Heat pump system of heat pump water heater

A heat pump water heater and heat pump system technology, which is applied to the improvement field of the heat pump system of the existing heat pump water heater, can solve the problems such as the reduction of the refrigerant circulation flow, the reduction of the heating capacity of the heat pump system, the increase of the exhaust pressure difference, and the improvement of the return flow. The effect of increasing the superheat of the air, improving the heating efficiency, and increasing the evaporation pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

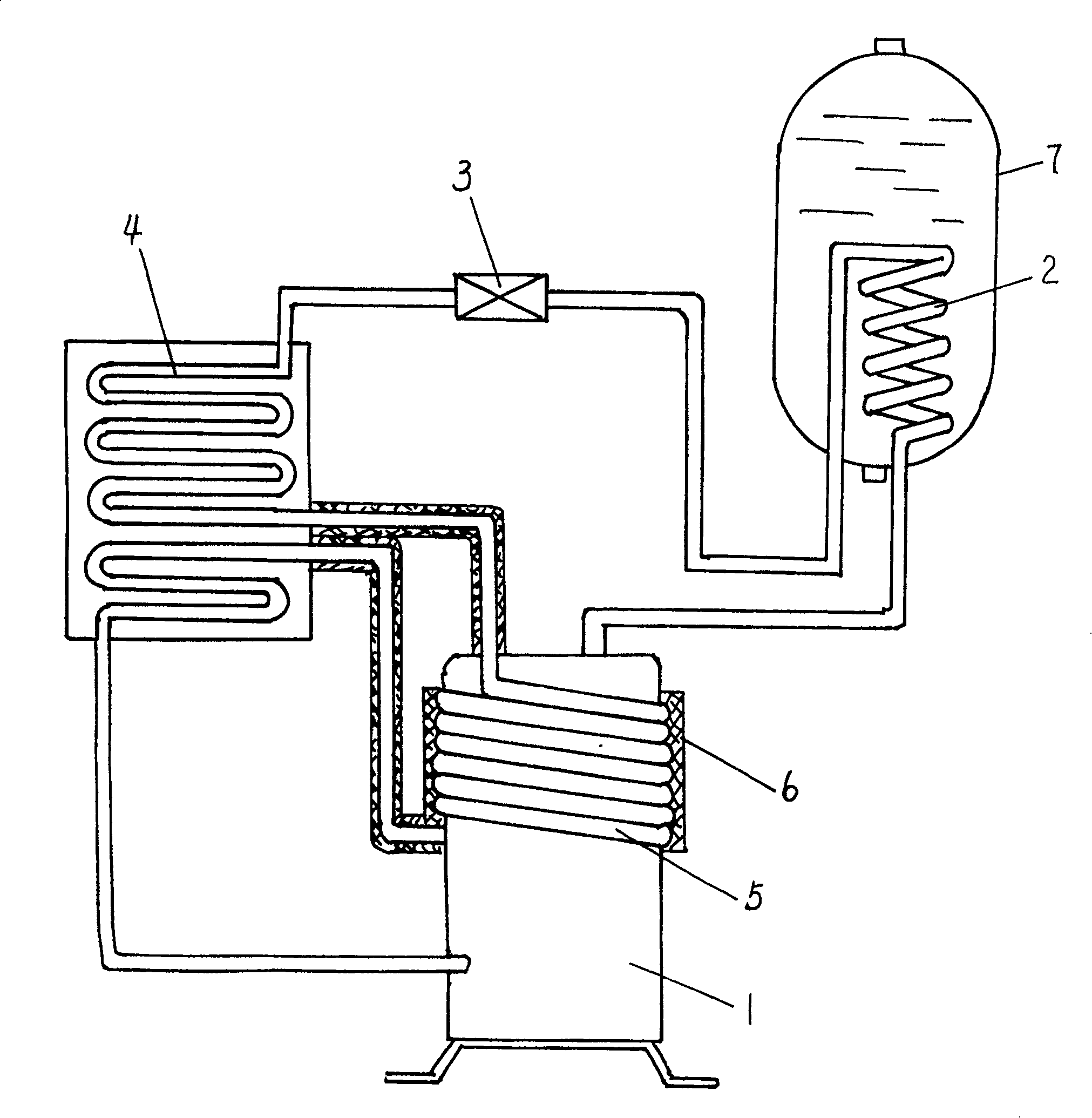

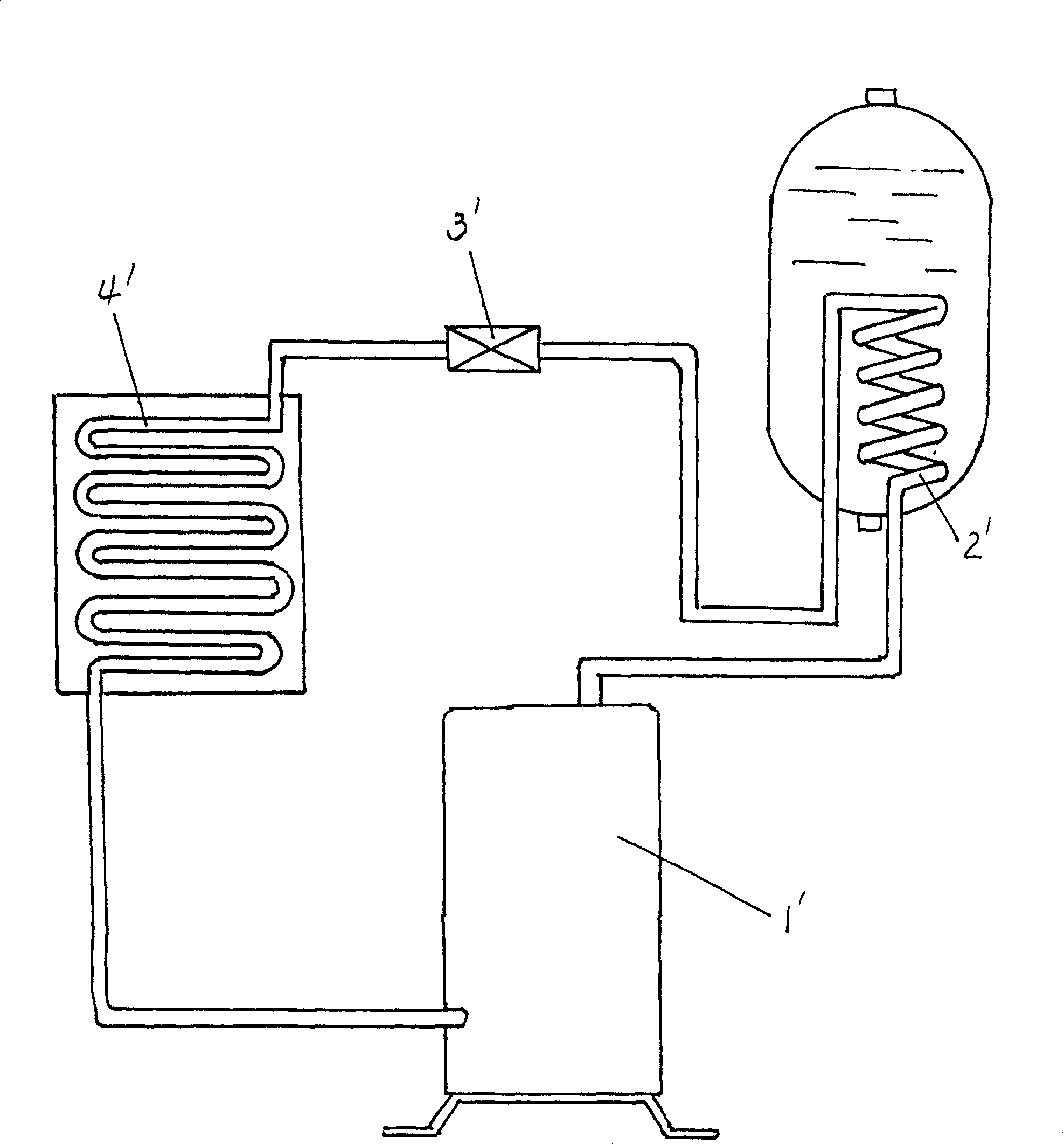

[0012] Please refer to figure 1 The heat pump system of the heat pump water heater of the present invention is mainly composed of a compressor 1, a condenser 2, a throttling element 3, and an evaporator 4 connected in sequence through conduits, and a coil 5 is coiled outside the shell of the compressor 1 , the coil 5 is a copper coil, and a pair of leading ends thereof are respectively connected in series with the circuit of the evaporator 4 . The outer surface of the coil pipe 5 is wrapped with a thermal insulation layer 6, and the thermal insulation layer 6 plays the role of thermal insulation. The throttling element 3 can be any one of a capillary tube, an electronic expansion valve, a thermal expansion valve, and a throttle valve.

[0013] Please see below figure 1 To describe the working process of the heat pump system of the present invention: the high-temperature and high-pressure gas from the compressor 1 is introduced into the condenser 2 through the copper pipe, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com