Outward discharging wet type two-effect drying heat pump unit

A heat pump unit, wet type technology, applied in dryers, drying, heat pumps, etc., can solve the problems of reduced waste heat recovery efficiency, unstable operation of the evaporator, and reduced enthalpy value, and achieve the effect of improving the heating energy efficiency ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

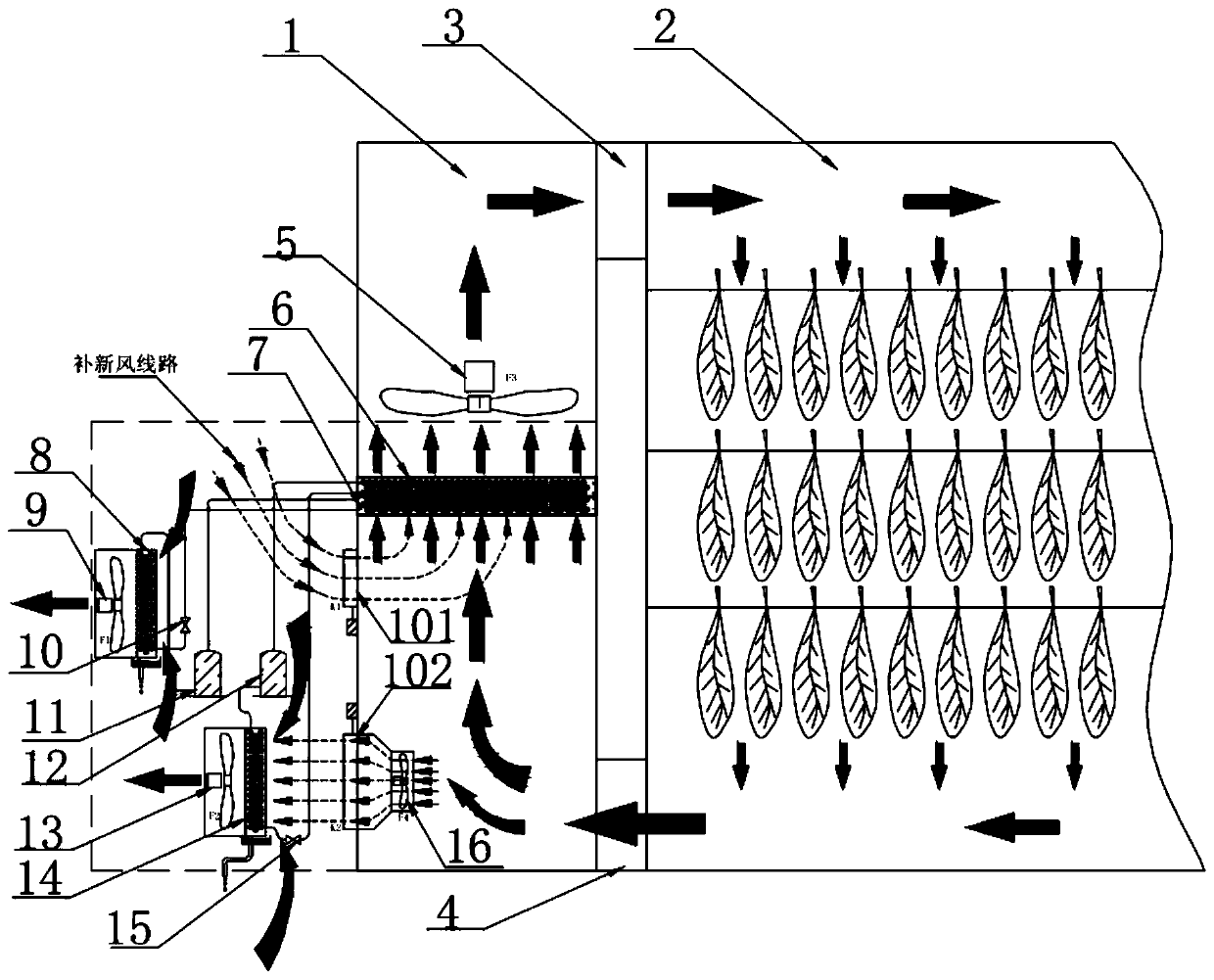

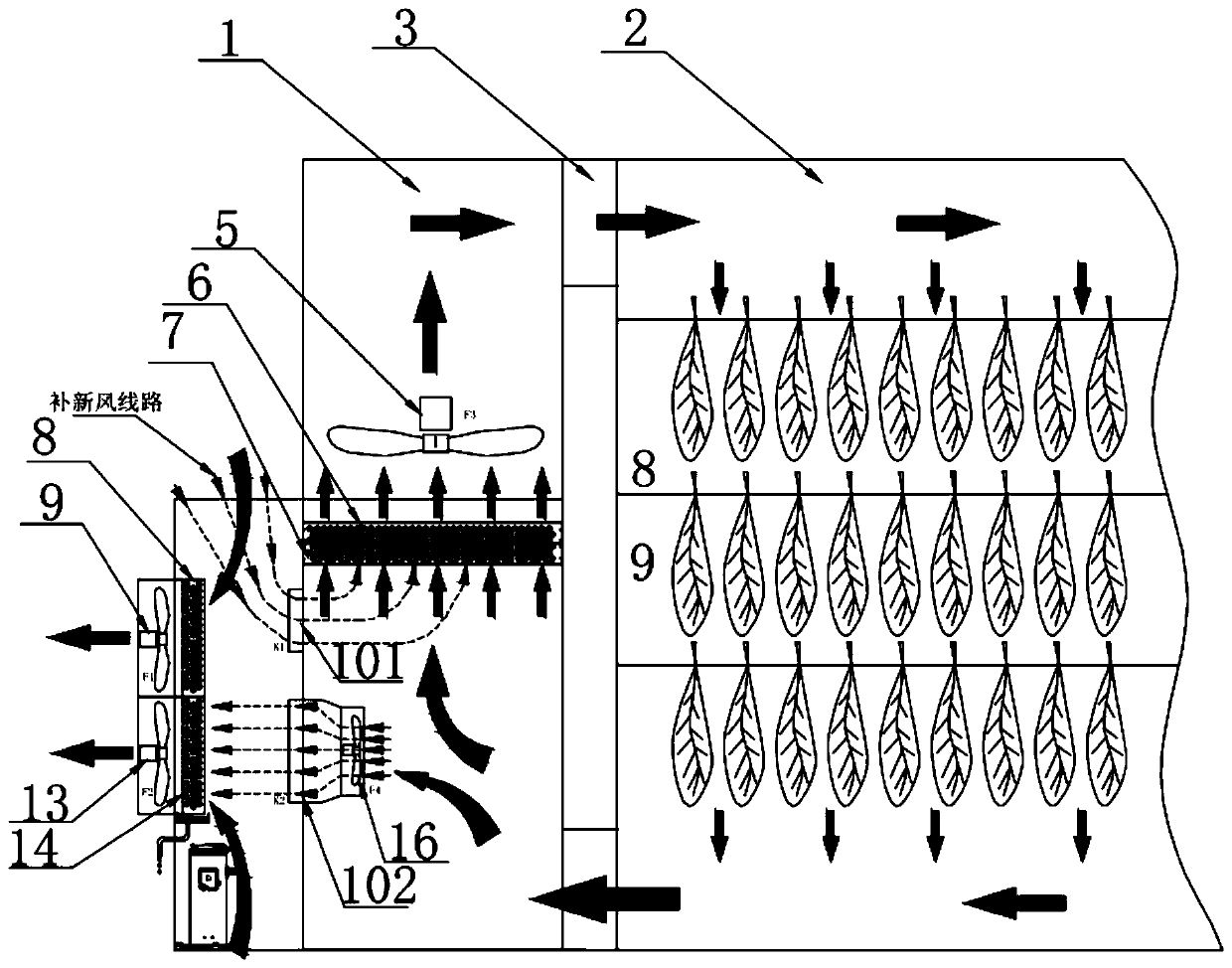

[0045] refer to Figure 1-Figure 3 , the present invention provides a heat pump unit for drying external moisture with two effects, which includes an air circulation channel 1, and the air circulation channel 1 includes an air inlet 4 and an air outlet 3 of the heat pump unit.

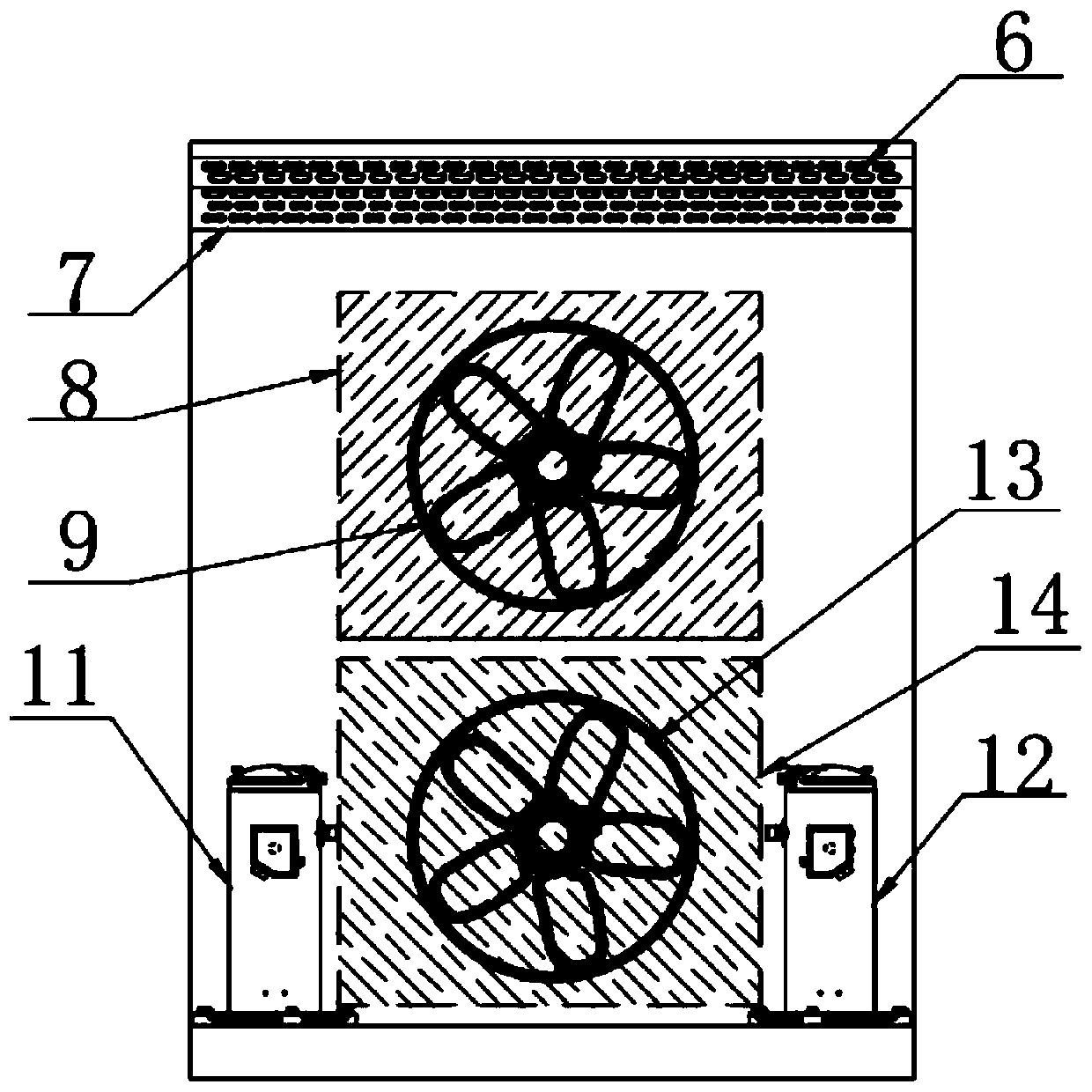

[0046] The external moisture-expelling two-effect tobacco leaf drying heat pump unit also includes at least two sets of heat pump units, each heat pump unit includes a compressor, a condenser, a throttling device, and an evaporator that are sequentially connected to form a refrigerant cycle; The evaporators are located in the ambient air outside the air circulation channel 1, and each condenser is located in the air circulation channel 1; the air circulation channel 1 is also provided with a dehumidification outlet 102 and a fresh air outlet 101, wherein at least one group of heat pump units evaporate The device is set at the dehumidification outlet 102 to recover the waste heat of the dehumidification...

Embodiment 2

[0087] This embodiment is the adjustment carried out on the basis of embodiment 1, as Figure 7 As shown in , the specific present embodiment omits the setting of the third fan 16, and the moisture discharge port 10 is provided with an orifice structure with an adjustable seal, and a dynamic and static valve connected with the moisture discharge port 102 is provided in the circulating air duct 1. The pressure conversion pipe 17, part of the warm and humid air entering the air circulation channel 1 from the air inlet 4 of the heat pump unit flows through the dynamic and static pressure conversion pipe 17, and the moisture discharge port 102 in sequence. Other structures of the external humidity-expelling two-effect tobacco leaf drying heat pump unit in this embodiment can refer to the description in Embodiment 1, and will not be repeated here.

[0088] In this embodiment, a dedicated dynamic-static pressure conversion pipe is installed at the air inlet 4 of the heat pump unit (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com