Condensed steam source heat pump driven steam boiler with economizer

A technology for driving steam and economizers, applied in the field of condensing steam source heat pumps driving steam boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

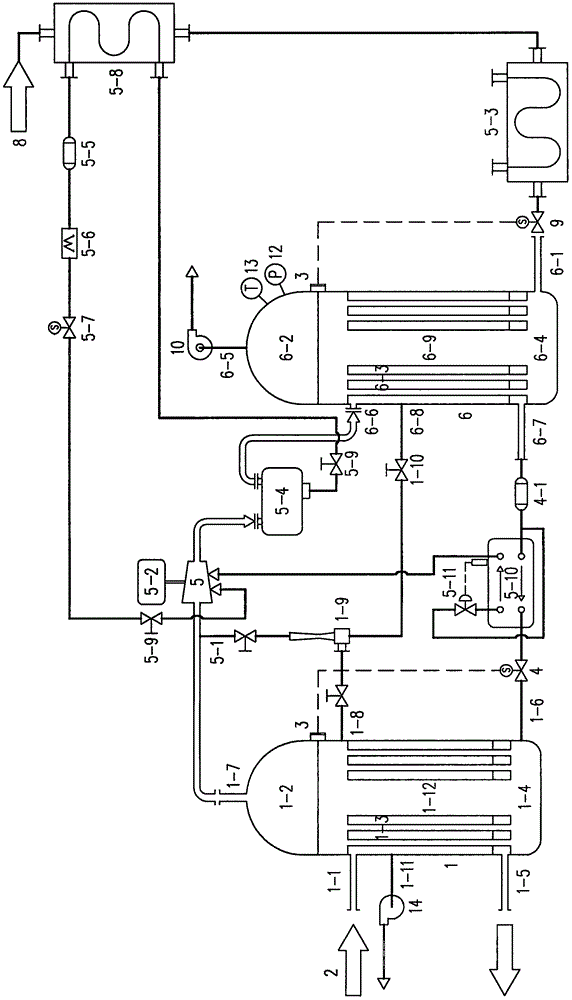

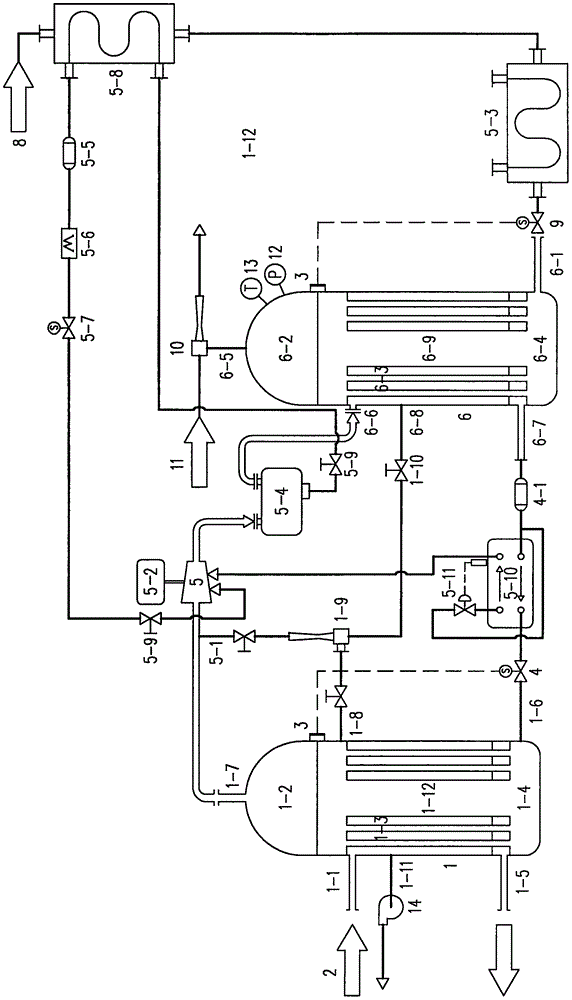

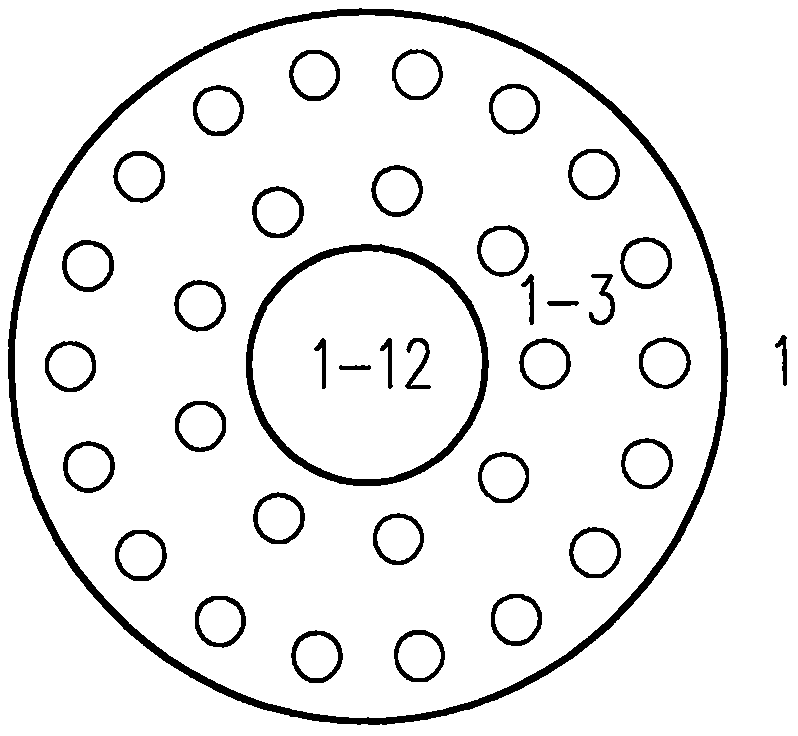

[0058] The embodiment of the steam boiler driven by the condensing steam source heat pump with economizer proposed by the present invention is attached figure 1As shown, the description is as follows: It is a rising film evaporator 1 with 4050kW of heat obtained by evaporation, installed vertically, and made of carbon steel with a siphon circulation in the tube and a countercurrent heat extraction; a stainless steel tube with a diameter of 200mm / wall thickness of 2.5mm has a condensing steam inlet 1-1; Cylindrical separation chamber 1-2 with a diameter of 1200mm / height 250mm; a ring with a diameter of 1200mm / height of 2000mm / diameter of 19mm distributed vertical siphon heat pipe clusters 1-3; a cylindrical shunt chamber with a diameter of 1200mm / height 250mm 1-4 ; condensate outlet 1-5 of stainless steel tube with diameter 40mm / wall thickness 1.5mm / length 60mm; copper tube liquid heat pump inlet 1-6 with diameter 60mm / wall thickness 1.5mm / length 60mm; diameter 120mm / wall thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com