Encirclement type road-vehicle hanger rail

A technology of hanging rails and guide rails, applied in the field of embracing road-vehicle hanging rails, can solve the problems of restricting the arrangement space of equipment in the suspended power cabin, complex stress on the train body structure, and increasing the cost of bow pillows, which is conducive to flexibility and flexibility. Layout, prevent derailment and rollover accidents, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following content is a detailed description of the present invention in conjunction with the accompanying drawings, and should not be construed as a limitation of the present invention.

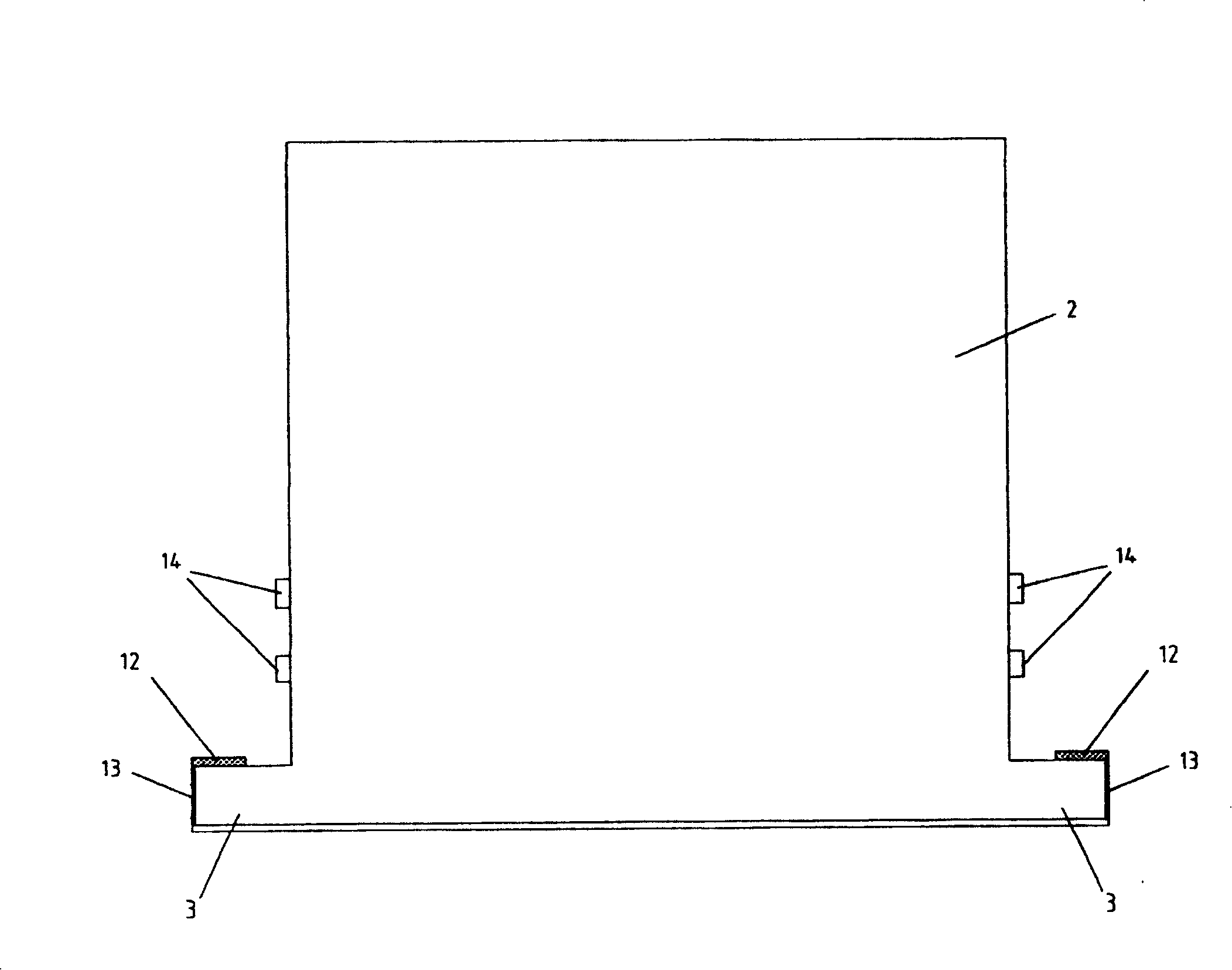

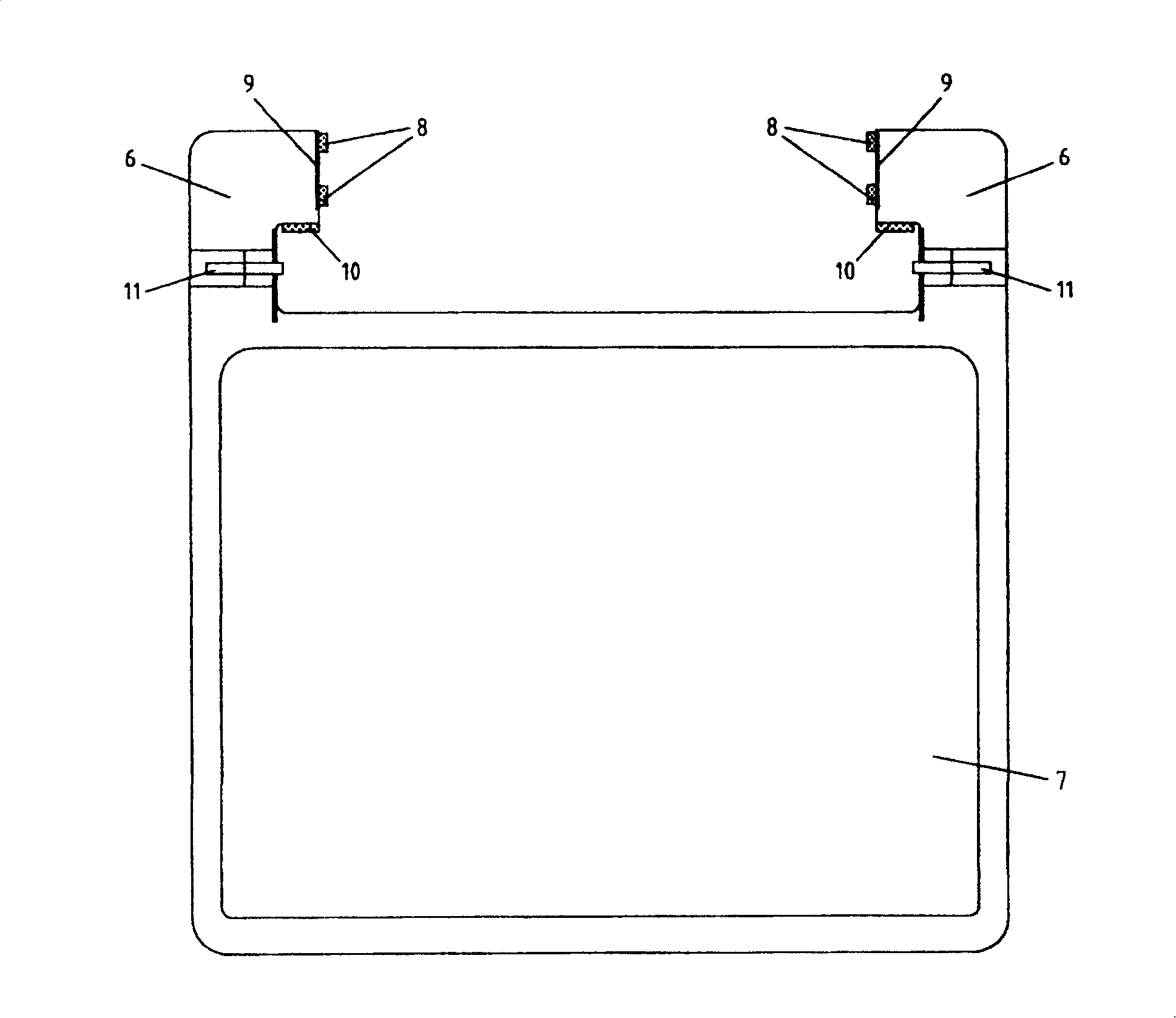

[0027] The embracing road-vehicle suspension rail of the present invention is composed of two parts, the box girder guide rail and the vehicle, and the carriage part is an upper and lower part made of one body, wherein the upper part is a suspension power cabin, which provides power for the train, and the lower part is for carrying people or Cargo compartment. Wherein the train carriage surrounds the road wing of the box girder guide rail.

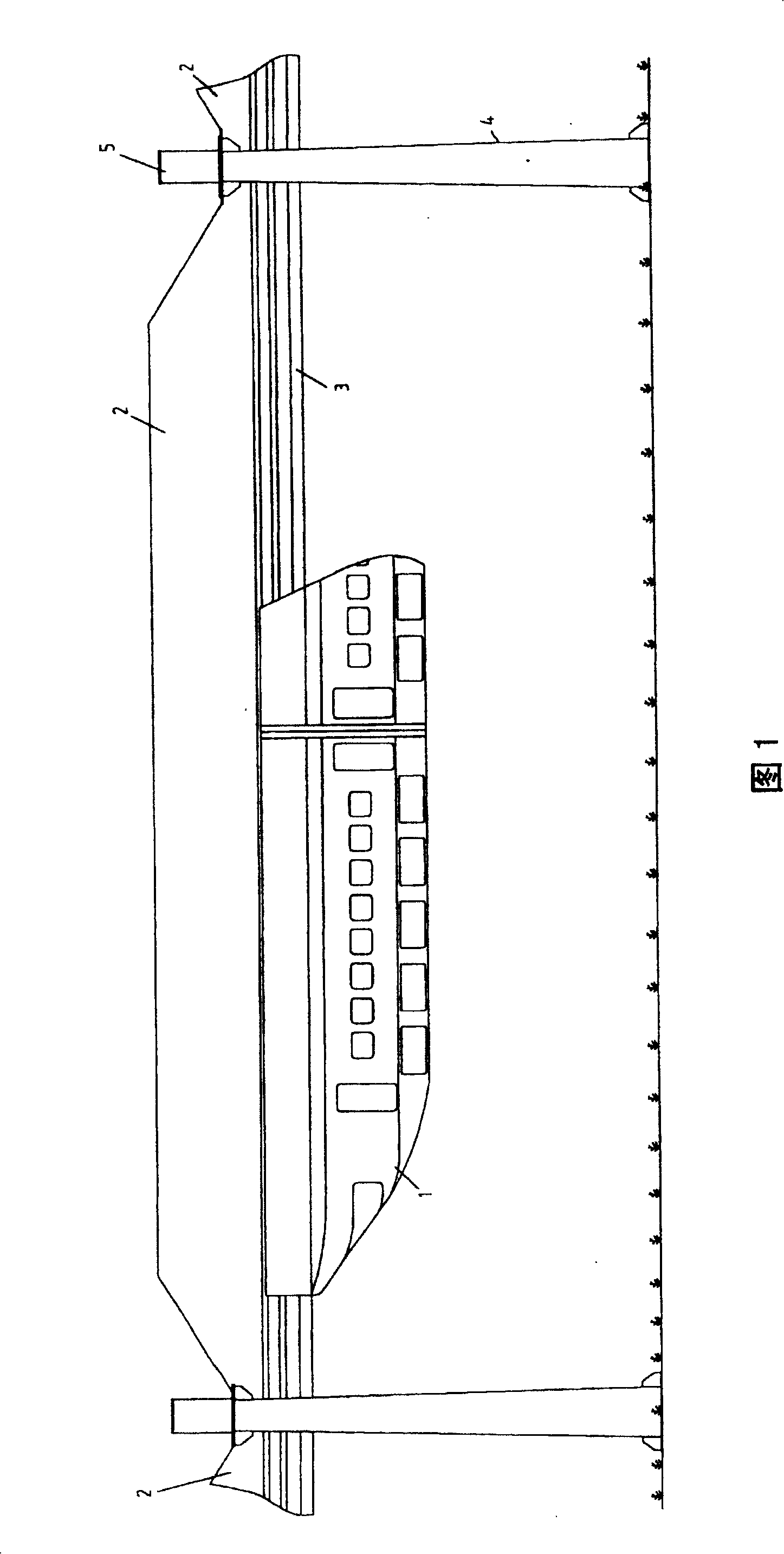

[0028] Specifically, please refer to FIG. 1 , which is a schematic side view of the layout of the suspension rail road car of the present invention. The two ends of the box-shaped beam guide rail 2 are fixed below the door beam 5 of the gantry 4, and every two box-shaped beams are smoothly connected, and a temperature joint is provided. Gantr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com