Design method for permanent magnet bias axial magnetic bearing

A technology for axial magnetic bearings and design methods, applied in the direction of shafts and bearings, bearings, mechanical equipment, etc., can solve problems such as poor accuracy, difficult processing, unreasonable permanent magnet size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

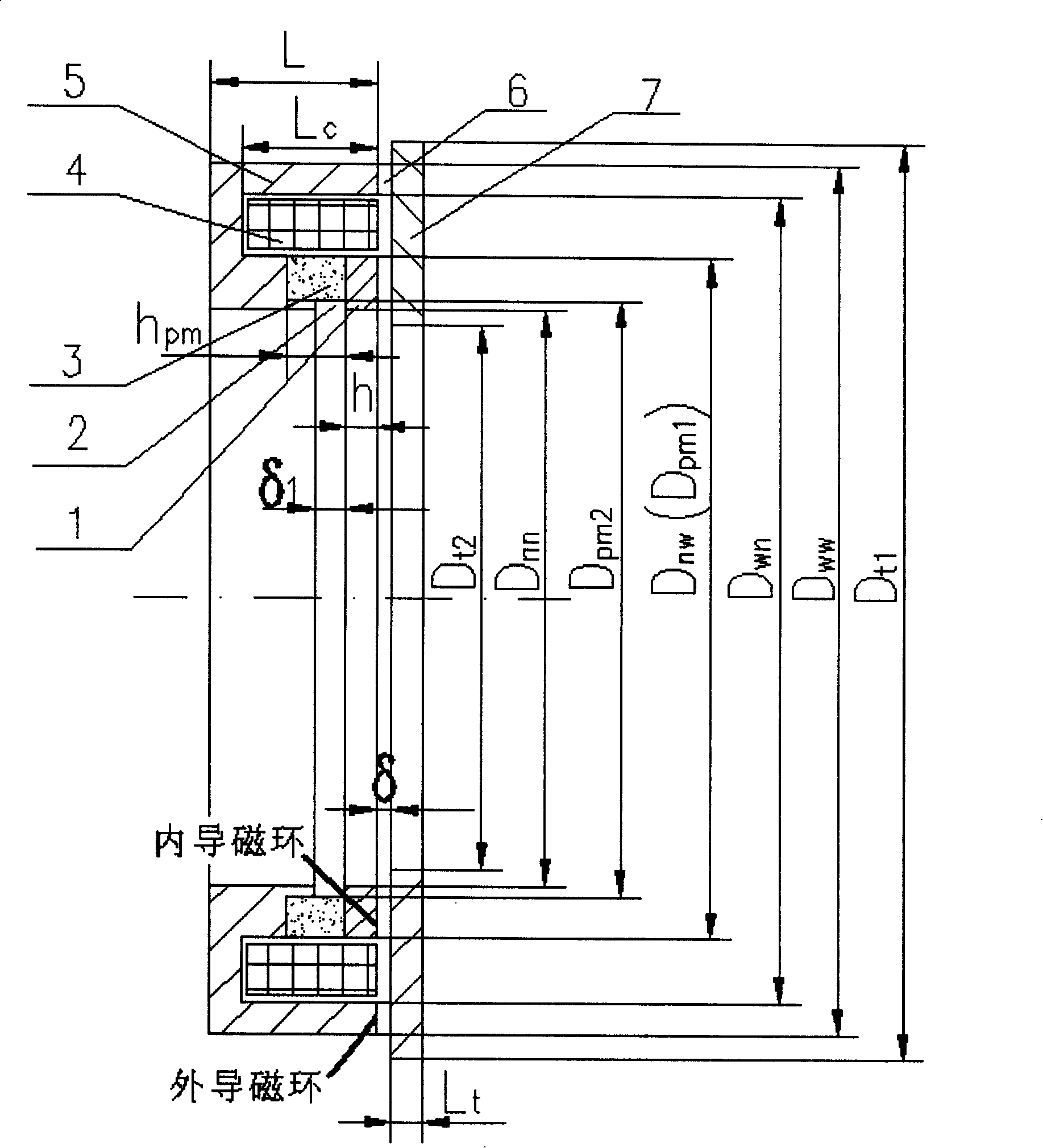

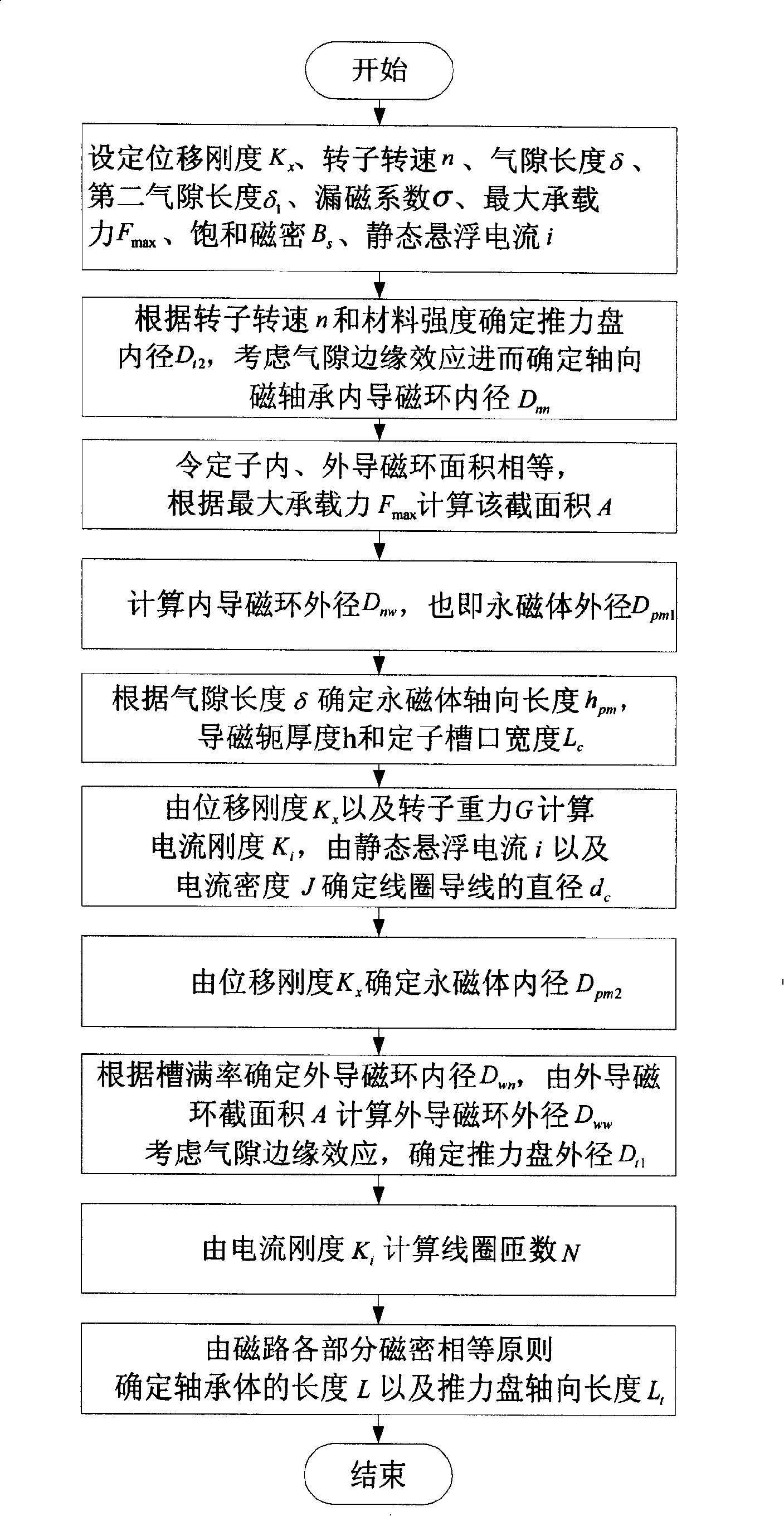

[0057] Such as figure 1 As shown, the design object of the present invention is a permanent magnetic bias axial magnetic bearing for a magnetic levitation flywheel. Among the figures, 1 is a magnetic yoke, 2 is a second air gap, 3 is a permanent magnet, 4 is a coil, and 5 is a bearing. body, 6 is the magnetic air gap between the bearing body (also known as the stator) and the thrust disc, and 7 is the thrust disc. Set the displacement stiffness K of the axial magnetic bearing according to the requirements of the existing magnetic bearing controller x It is -0.7N / um, and the air gap length δ is set to 0.25mm according to the existing processing level. The second air gap loses too much magnetomotive force, so the length of the second air gap should be slightly greater than twice the length of the air gap, and here the second air gap δ 1 According to the magnetic field analysis of the magnetic bearing, the magnetic leakage coefficient σ is set to 1.3, and the maximum bearing ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com