Equipment for making hot-filling polyester bottle

A technology for processing equipment and PET bottles, applied in the processing field of plastic packaging containers, can solve the problems of unreasonable structure, low scrap rate and high scrap rate, and achieve the effect of reasonable structure and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

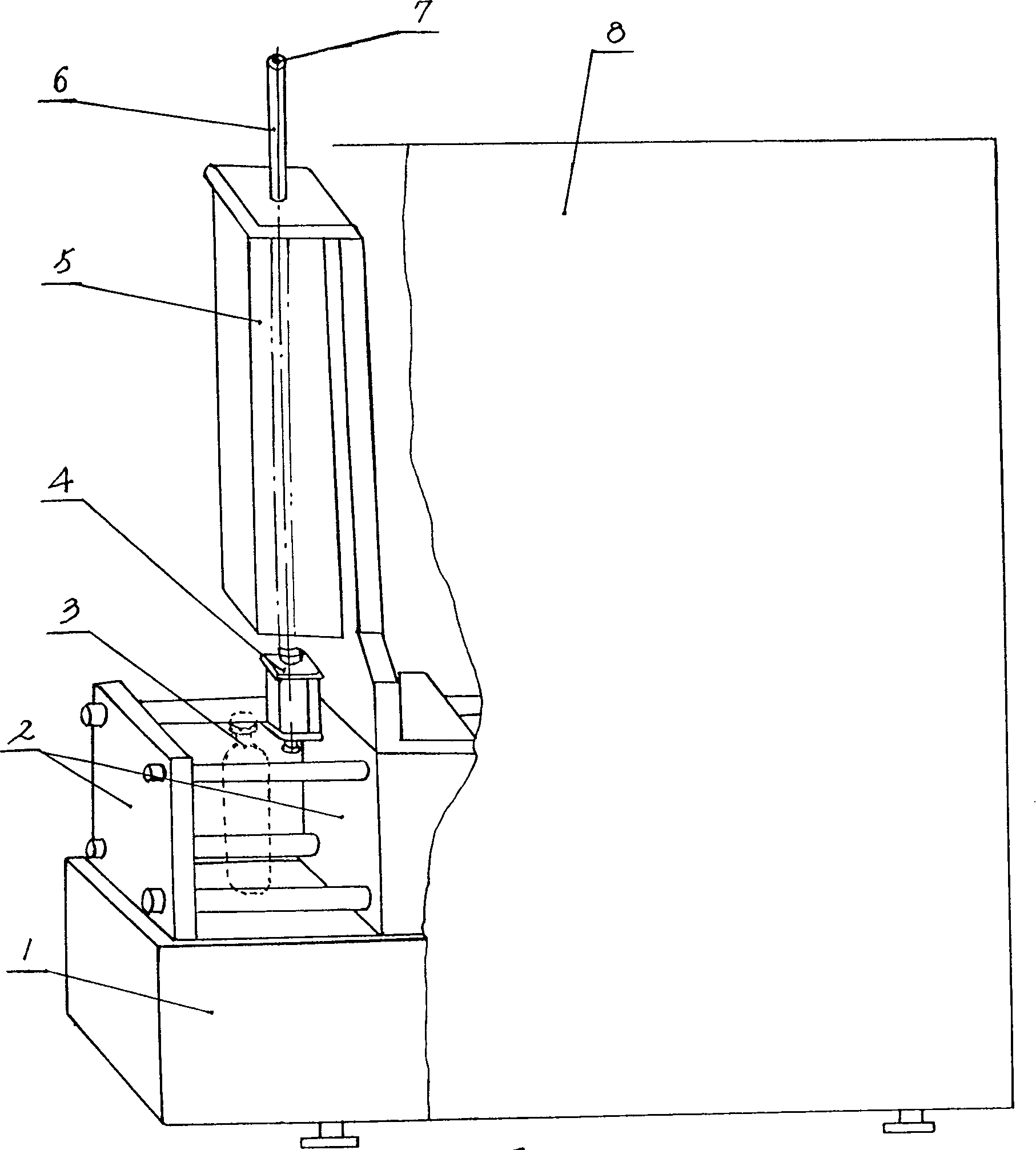

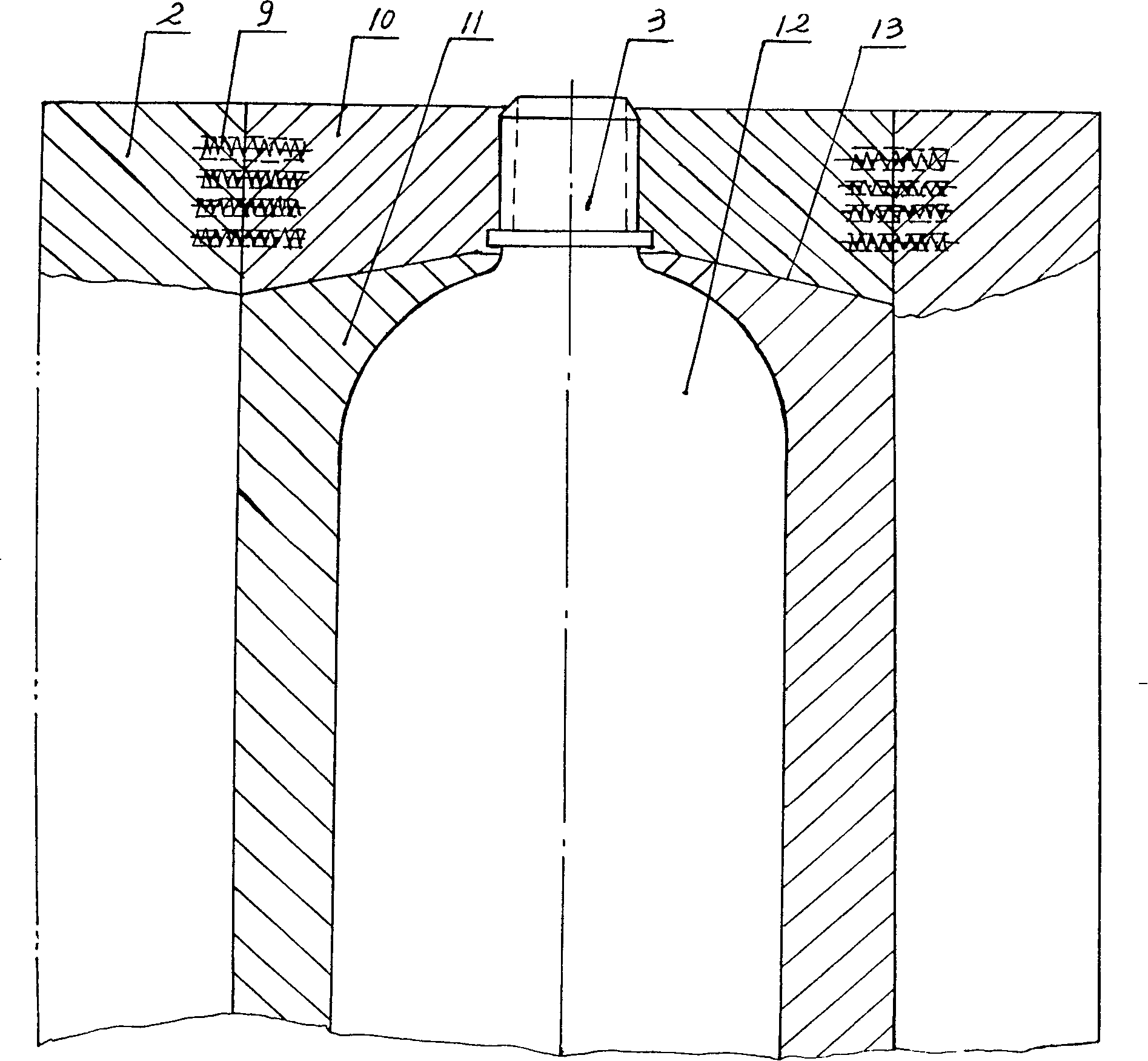

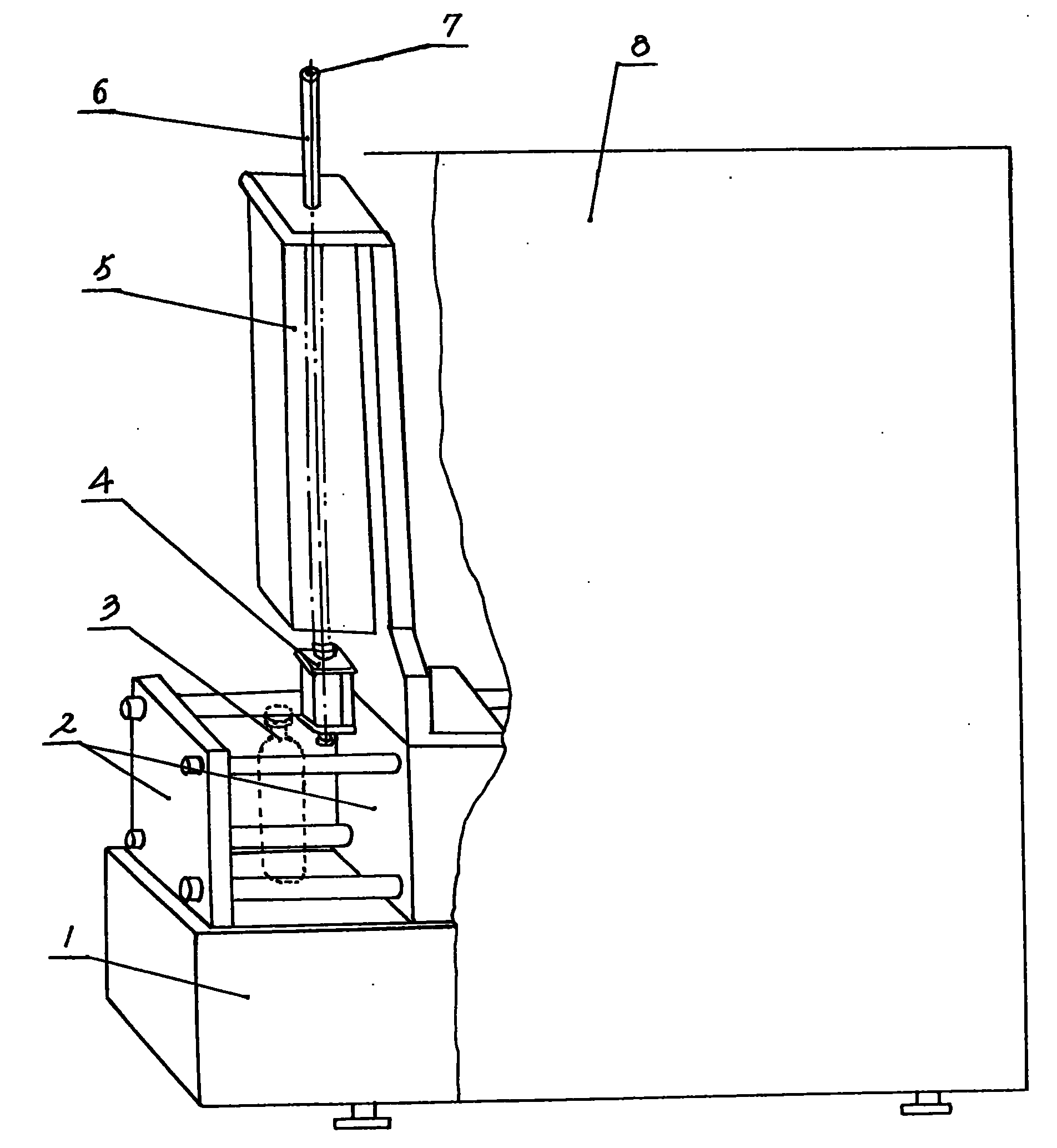

[0014] refer to figure 1 , figure 2 , a processing equipment for hot-filling polyester bottles, comprising a base 1, a stretch-blow machine, said stretch-blow machine comprising a stretch rod 6, a stretch cylinder 5, a blow cylinder 4 and a locking plate 2, said The locking plate 2 is fixedly connected with the thermal mold 11, the polyester bottle mouth of the thermal mold 11 cooperates with the blowing cylinder 4, the stretch rod 6 passes through the blowing cylinder 4 and the stretching cylinder 5, the described The center of the stretch rod 6 is provided with a vent hole 7, and its main technical feature is that a bottle mouth clamping block 10 is installed above the hot mold 11, and there is a compression spring 9 on the outside of the clamping block 10, and the other end of the compression spring 9 is Connect to lock template 2.

[0015] There is an oblique l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com