Grafted polypropylene diaphragm and manufacturing method

A technique of grafting polypropylene and manufacturing methods, which is applied in the direction of separators/films/diaphragms/spacers, textiles and papermaking, electrical components, etc., and can solve the impact of the environment, personnel safety, unreachable, complex technical conditions, etc. problems, to overcome adverse effects, improve uniformity, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

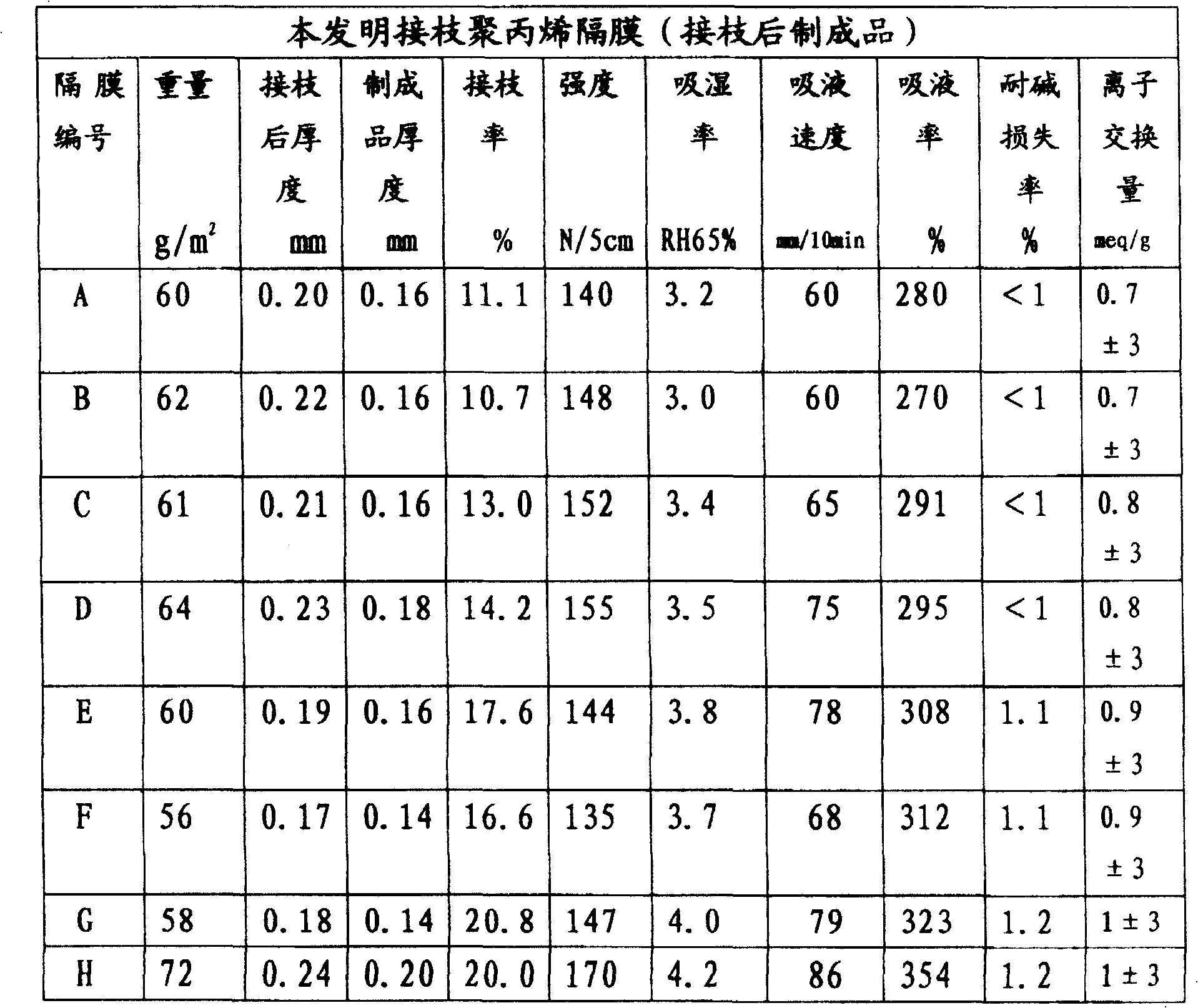

[0026] Example 1 Preparation of grafted polypropylene diaphragm A

[0027] Follow these steps:

[0028] ① Hydrophilic pretreatment of raw fiber

[0029] First use demetallized water and high-efficiency hydrophilic penetrating agent (sodium isomeric fatty alcohol oxirane sulfonate) to prepare circulating water by mixing at a weight ratio of 1000:8;

[0030] Take the raw material fiber according to the following proportioning: two-component low-melting point hot-melt composite fiber (diameter 1.5dtex length 3mm) 9.6kg, accounting for 80wt%, two-component low-melting point hot-melt composite fiber (diameter 2dtex, length 4mm) 1.2 kg, accounting for 10wt%, and vinylon superfine fiber (model BSSF-1, diameter 0.5dtex, length 3mm) 1.2kg, accounting for 10wt%, put into the pulp storage tank (volume 20M 3 ) in the paper-making circulating water, mixed with the paper-making circulating water for beating, diluting, and dispersing until the raw material fiber is in the form of a single ...

Embodiment 2

[0039] Example 2 Preparation of grafted polypropylene diaphragm B

[0040] Follow these steps:

[0041] ① Hydrophilic pretreatment of raw fiber

[0042] First use demetallized water and high-efficiency hydrophilic penetrating agent (sodium isomeric fatty alcohol oxirane sulfonate) to prepare circulating water by mixing at a weight ratio of 1000:8;

[0043] Weigh the raw material fiber according to the following ratio: two-component low-melting point hot-melt composite fiber (diameter 1.5dtex length 3mm) 8.4kg, accounting for 70wt%, two-component low-melting point hot-melt composite fiber (diameter 2dtex, length 4mm) 1.2 kg, accounting for 10wt%, vinylon superfine fiber (model BSSF-1, diameter 0.5dtex, length 3mm) 2.4kg, accounting for 20wt%, put into the pulp storage tank (volume 20M 3 ) in the paper-making circulating water, mixed with the paper-making circulating water for beating, diluting, and dispersing until the raw material fiber is in the form of a single fiber and s...

Embodiment 3

[0046] Example 3 Preparation of grafted polypropylene diaphragm C

[0047] Follow these steps:

[0048] ① Hydrophilic pretreatment of raw fiber

[0049] First use demetallized water and high-efficiency hydrophilic penetrating agent (sodium isomeric fatty alcohol oxirane sulfonate) to prepare circulating water by mixing at a weight ratio of 1000:8;

[0050] Weigh the raw material fiber according to the following ratio: two-component low-melting point hot-melt composite fiber (diameter 1.5dtex length 3mm) 7.8kg, accounting for 65wt%, two-component low-melting point hot-melt composite fiber (diameter 2dtex, length 4mm) 1.2 kg, accounting for 10wt%, vinylon superfine fiber (model BSSF-1, diameter 0.5dtex, length 3mm) 3.0kg, accounting for 25wt%, put into the pulp storage tank (volume 20M 3 ) in the paper-making circulating water, mixed with the paper-making circulating water for beating, diluting, and dispersing until the raw material fiber is in the form of a single fiber and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com