Socket for electronic module

A technology for electronic modules and sockets, which is applied in the field of sockets for electronic modules, can solve the problems of increased socket height, insufficient elasticity, inconvenient operation, etc., and achieve a firm locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

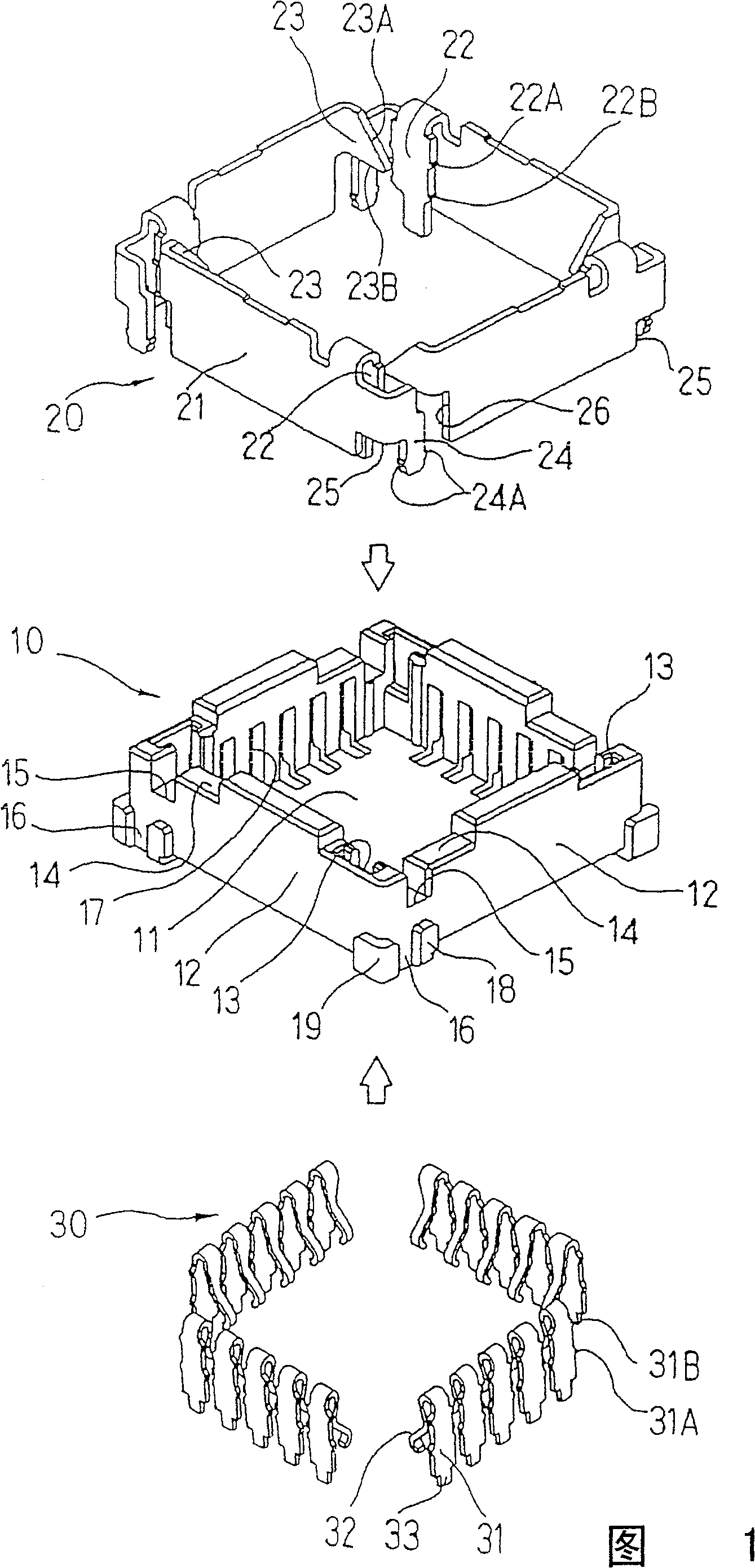

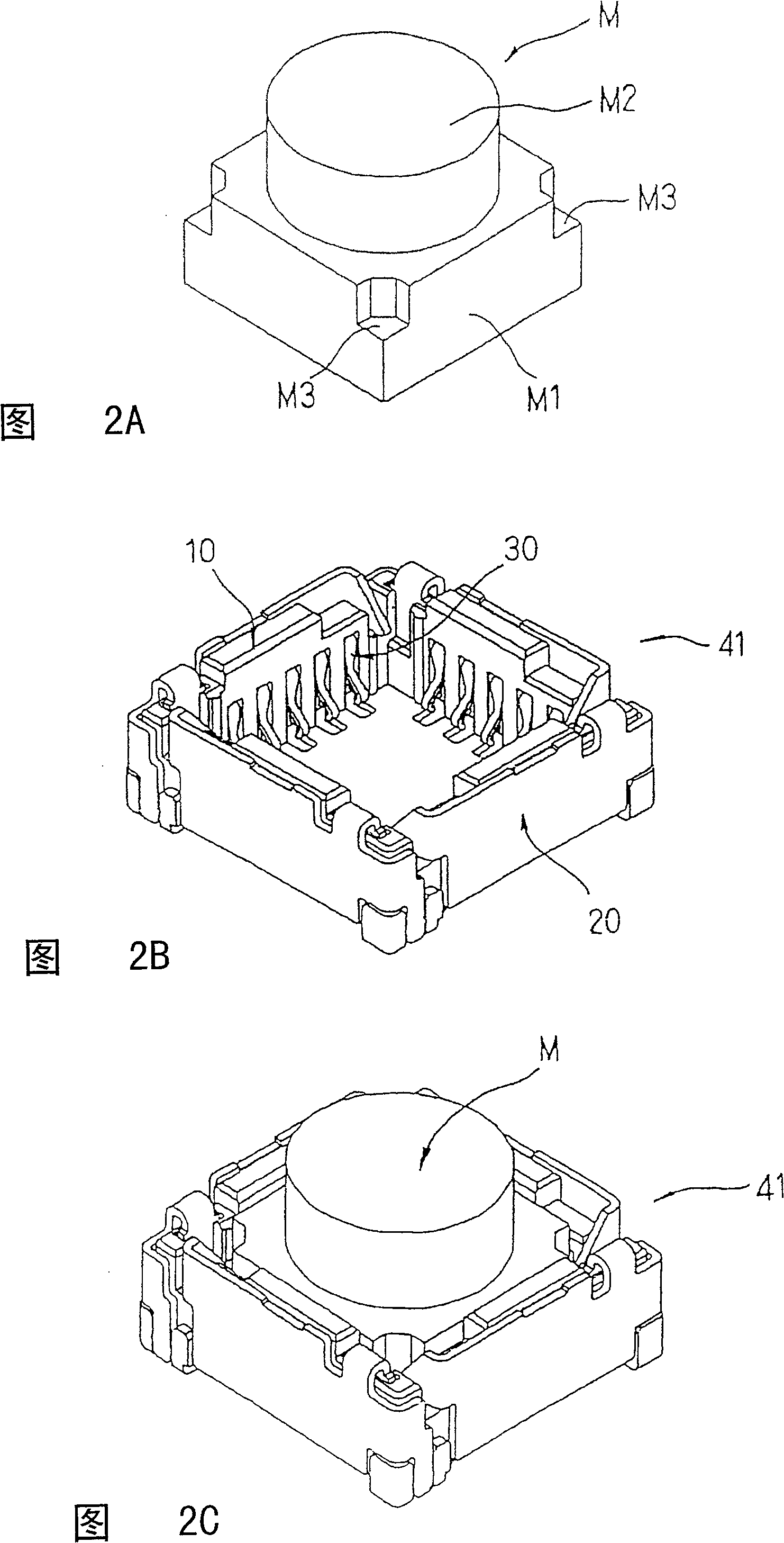

[0040] FIG. 1 is a perspective view of a separated state before assembly of each member constituting the socket for an electronic module according to one embodiment of the present invention.

[0041] In the figure, 10 is a casing made of an electrically insulating material, and a locking member 20 made of a metal plate and a terminal 30 are attached to the casing 10 .

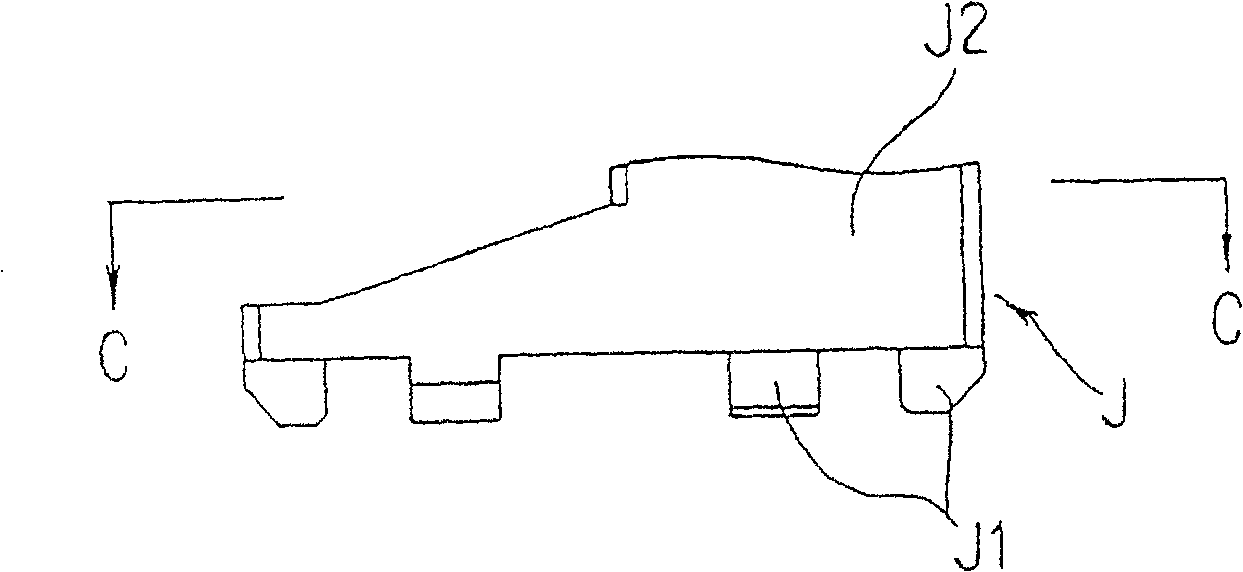

[0042]The casing 10 has a plate-shaped bottom wall portion 11 and a quadrangular peripheral wall 12 vertically erected from the peripheral portion thereof. The surrounding wall 12 forms a space inside it as a housing part for housing the module, and the module is stored in the housing part, and the bottom wall part 11 restricts the further movement of the module in the housing direction. The wall portions on the four sides of the peripheral wall 12 are formed in the same manner in the circumferential direction. When the side of each wall portion is viewed from the outside, on the right side, the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com