Positive-negative integral current lead structure with screw section and its manufacturing method

A current lead, spiral technology, applied in the field of low temperature and superconducting applications, can solve the problems of unbalanced temperature field, increased heat leakage of lead wires, unbalanced cooling airflow distribution, etc., achieve good symmetry and synchronization, and increase stability. , the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

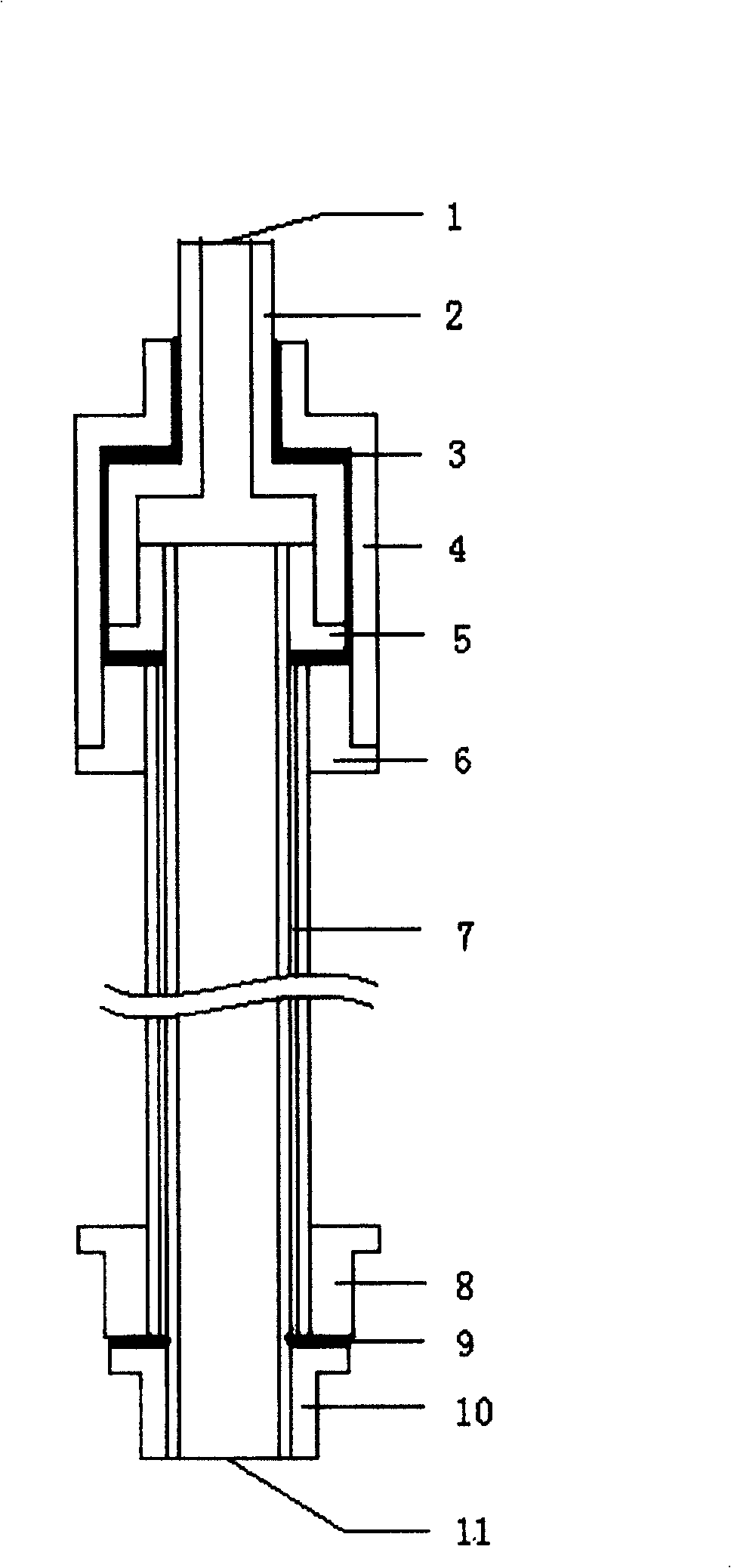

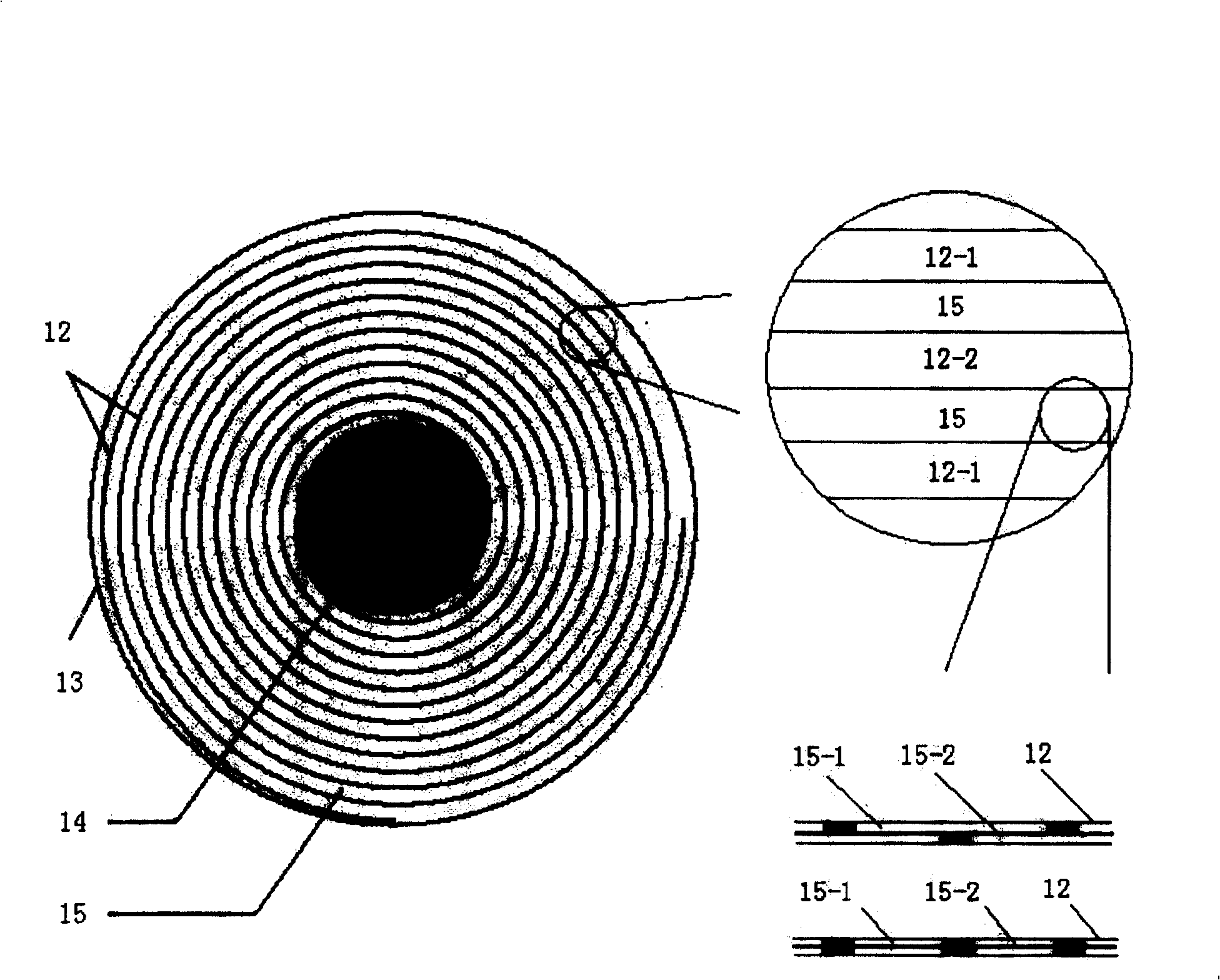

[0023] figure 1 It is a positive and negative integrated current lead overall structure with a spiral cross section. figure 2 Is the cross-sectional schematic diagram of the main part of the lead wire. Lead body 7 is composed of positive and negative copper coils 12, electrical insulating cylinder 13, electrical insulating rod 14, airflow channel 15-1 and electrical insulating layer 15-2, electrical insulating rod 14 is located in the middle, and electrical insulating cylinder 13 is on the outermost. The positive and negative copper coils 12 , the airflow channel 15 - 1 and the electrical insulating layer 15 - 2 are spirally wound around the electrical insulating rod 14 as the center.

[0024] The main body of the lead wire is composed of positive and negative copper coils, an airflow channel and an electrical insulation layer, an electrical insulation rod in the middle and an electrical insulation cylinder outside. The positive and negative copper coils carry the current o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com