Aqueous high molecular polymer, coagulated dehydrant for sludge and sludge coagulating method

A water-soluble polymer and polymer technology, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of corrosion of manufacturing equipment, production of dioxins, insufficient performance of sludge filter cake, etc., and improve the cohesion performance. , the effect of improving work efficiency, improving cohesion performance or peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0083] The following examples illustrate the present invention, but the present invention is not limited by these examples.

[0084] In addition, in the following examples, N,N-dimethylaminoethyl methacrylate tertiary amine citrate is recorded as DM citrate, and N,N-dimethylaminoethyl methacrylate tertiary Amine malate is recorded as DM malate, methacrylic acid N,N-dimethylaminoethyl ester tertiary amine hydrochloride is recorded as DM hydrochloride, methacrylic acid N,N-diethylaminoethyl The ester tertiary amine citrate is recorded as DE citrate, the methacrylic acid N,N-diethylaminoethyl ester tertiary amine malate is recorded as DE malate, and the methacrylic acid N,N-diethyl Aminoethyl ester tertiary amine hydrochloride is denoted as DE hydrochloride, acrylamide is denoted as AAm, acrylic acid is denoted as AAc, and 2-acrylamidopropanesulfonic acid is denoted as ATBS.

[0085] (Measurement method of infrared spectrophotometry)

[0086] The measurement was carried out usi...

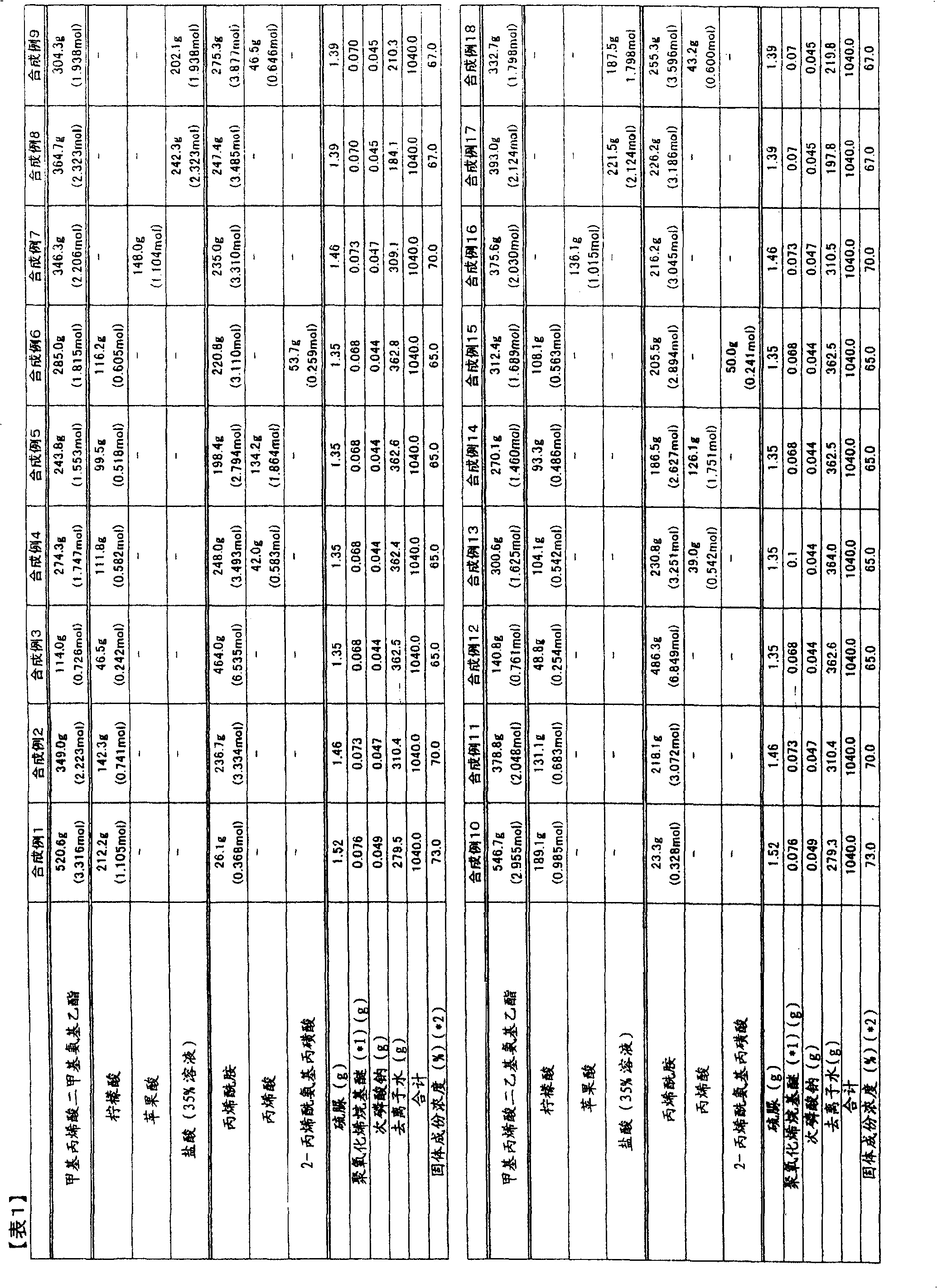

Synthetic example 1

[0110] Add 520.6g (3.316mol) N,N-dimethylaminoethyl methacrylate, 212.2g (1.105mol) citric acid, 26.1g (0.368mol) acrylamide, 1.52g thiourea to 279.5g deionized water successively , 0.076g polyoxyalkylene alkyl ether (HLB value is about 11), 0.049g sodium hypophosphite, and stir, synthesized the mixture of DM citrate monomer and AAm that solid content concentration is 73.0% (composition ratio is 90 mol%: 10 mol%). Table 1 shows the amount of raw materials used.

Synthetic example 2

[0112] Using the same method as in Synthesis Example 1, a mixture of DM citrate monomer and AAm (composition ratio: 40 mol %: 60 mol %) having a solid content concentration of 70.0 % was synthesized. Table 1 shows the amount of raw materials used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com