Line ice-melting method for extra-high voltage DC electric transmission system

A technology of UHV DC and power transmission system, which is applied in the installation of cables, electrical components, overhead installation, etc., and can solve the problems of increased investment, power line icing accidents, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

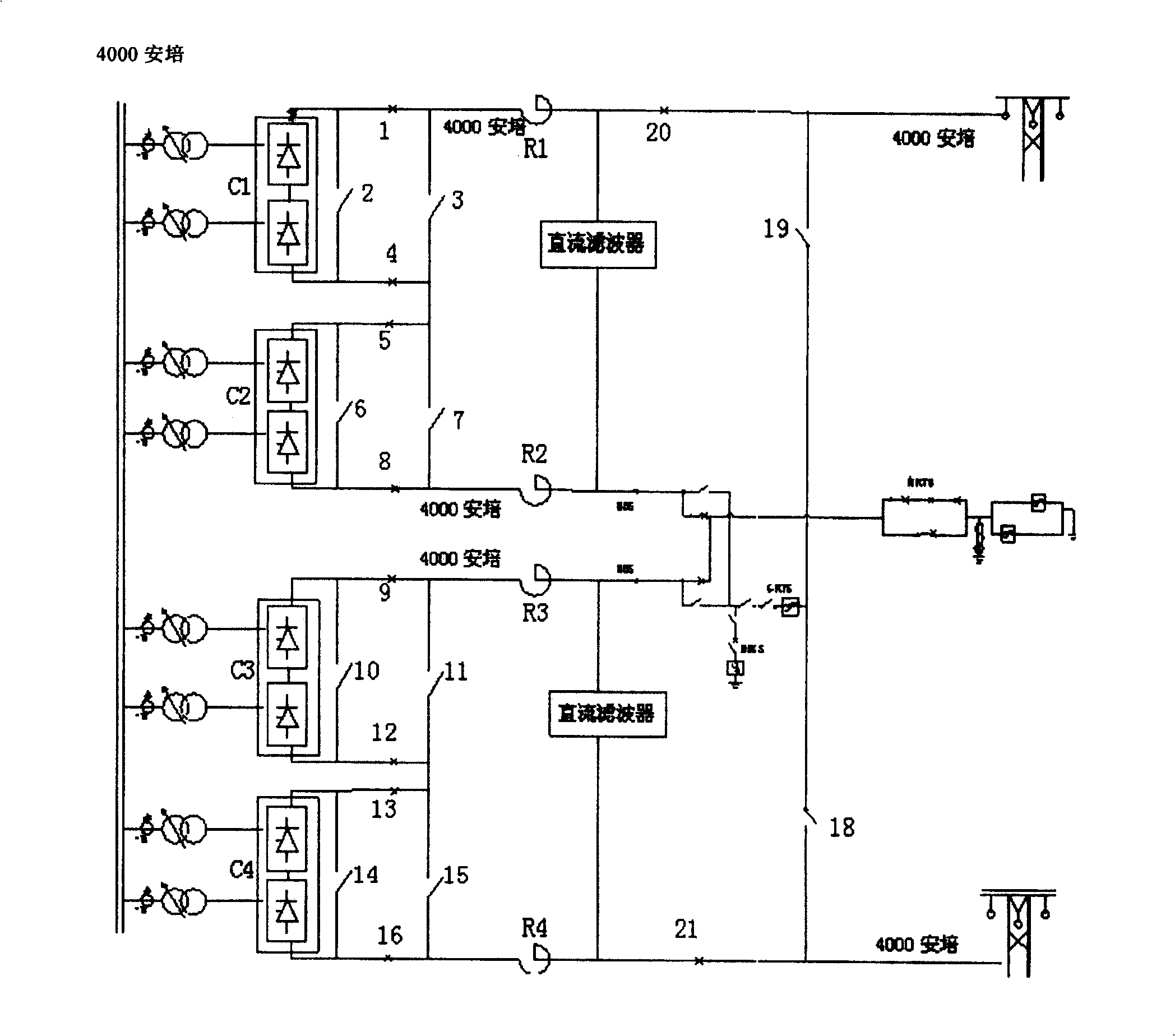

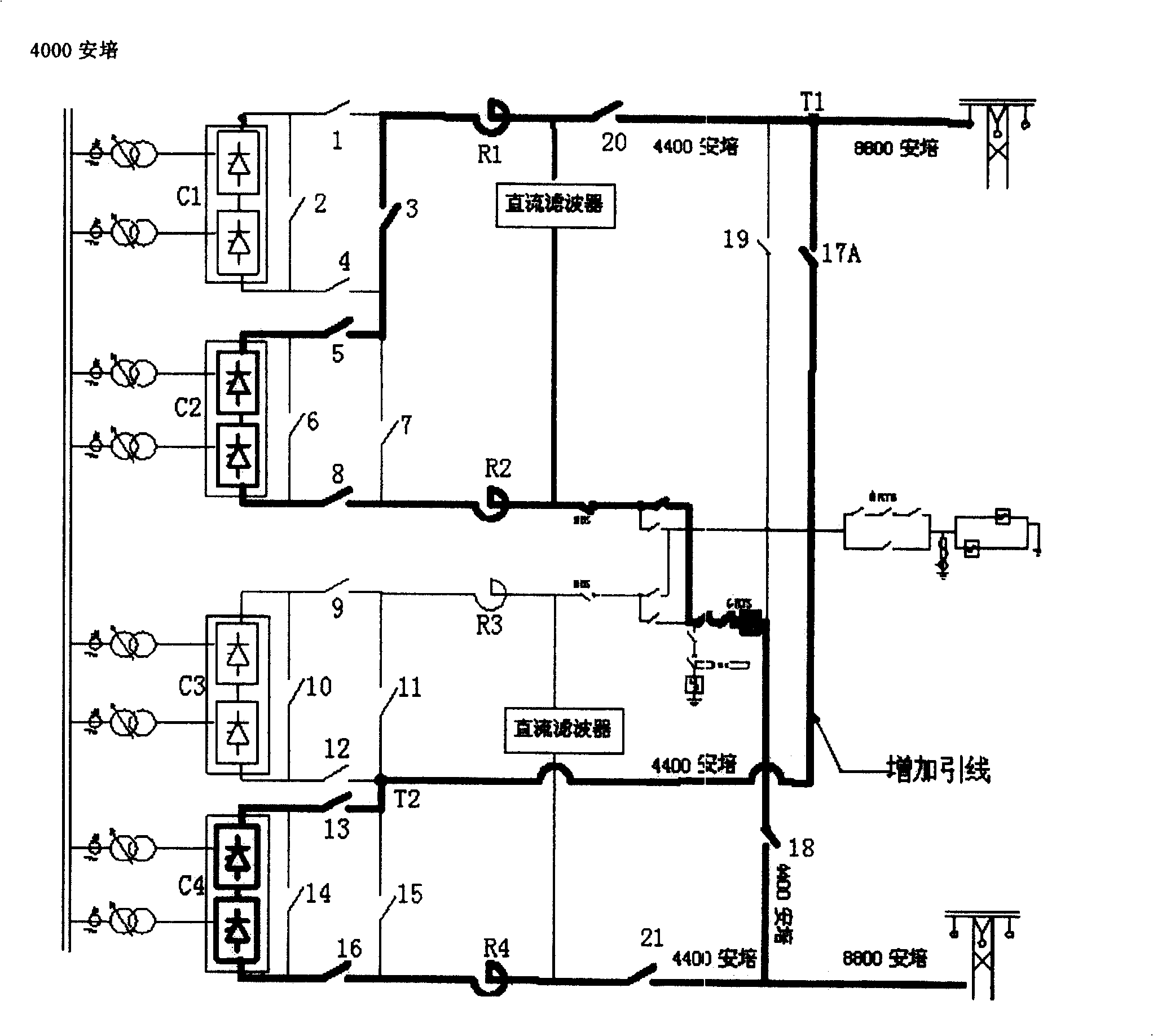

[0020] Example 1: Two inverters with two poles

[0021] Figure 2 shows the parallel connection diagram of two DC deicing bipolar converters, which can use any converter of one pole and the high-end converter (C1 or C4) of the other pole to form a parallel connection. A high-side converter is necessary because the low-voltage side of the converter needs to withstand voltages of opposite polarity in a parallel connection. Taking converters C2 and C4 as an example, as shown in FIG. 2 , a connecting line is added at the low voltage end of C4 to the outside of the line isolating switch 20 of the other pole, that is, the connecting line between T1 and T2. If an isolating switch 17A is added on the connection line, online melting of ice can be realized. The process is as follows: first close the switches 20, 3, 5, 8, and 18, turn the converter C2 into the metal loop operation mode, close the switches 17A, 13, 16, and 21, so that the converter C4 is connected to the loop, Then inver...

Embodiment 2

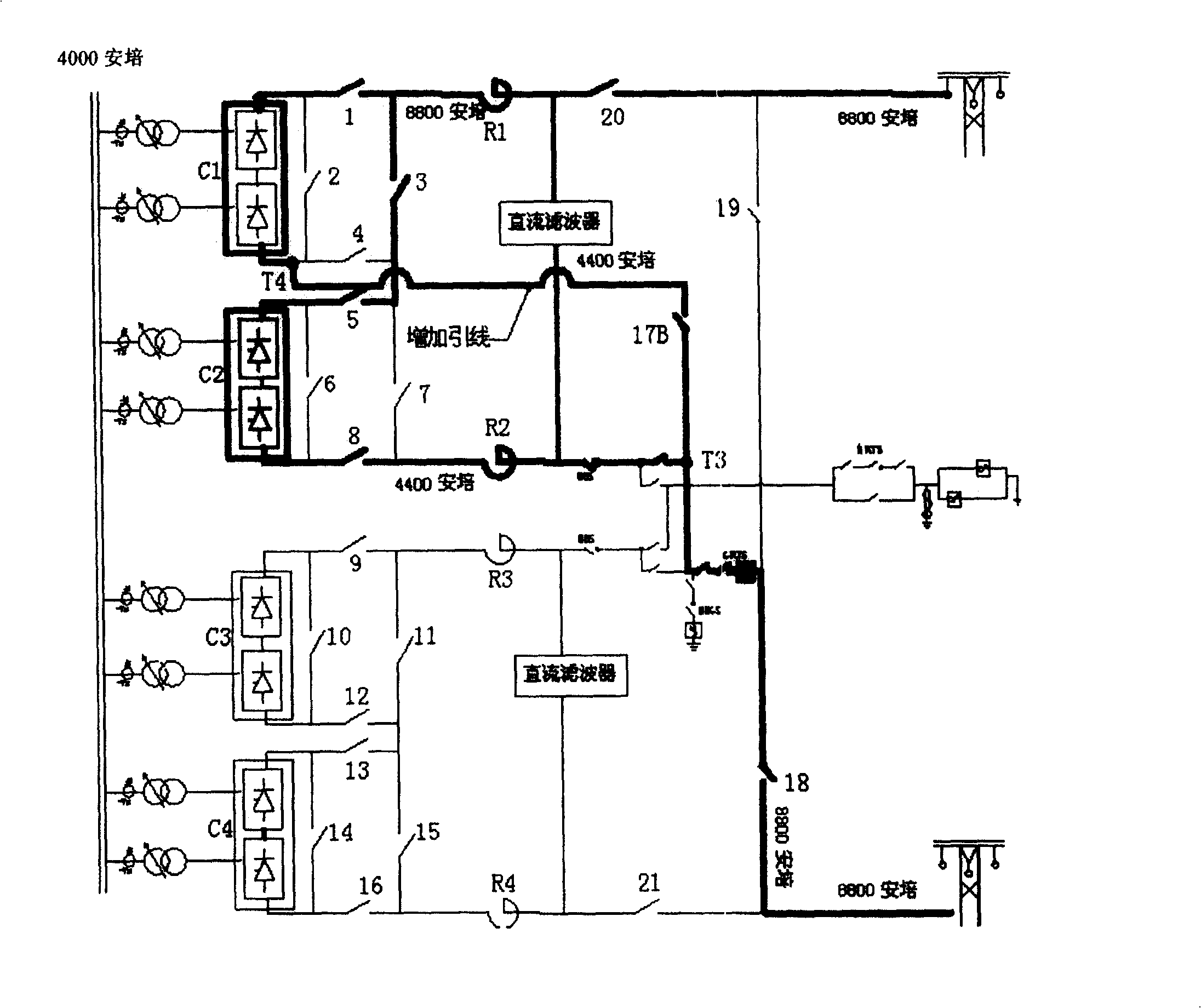

[0022] Example 2: Two converters of the same pole are connected in parallel

[0023] Figure 3 is a wiring diagram of parallel connection of two converters of DC ice-melting single pole, in which two converters of the same pole are connected in parallel, that is, converters C1 and C2 in the figure, or converters C3 and C4 ; The opposite end converter station adopts the same wiring.

[0024] Taking converters C1 and C2 as an example, a connection line is added from the low-voltage end of converter C1 to the DC neutral line, that is, the connection line between T3 and T4. At the same time, an isolating switch 17B is added on the connection line between T1 and T2, and this solution can realize ice melting without power failure. First close the switches 20, 3, 5, 8, and 18, and the converter station is converted to the single-pole single-converter C2 metal loop operation, and then close the isolation switches 1 and 17B to start the high-end converter and increase the current . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com