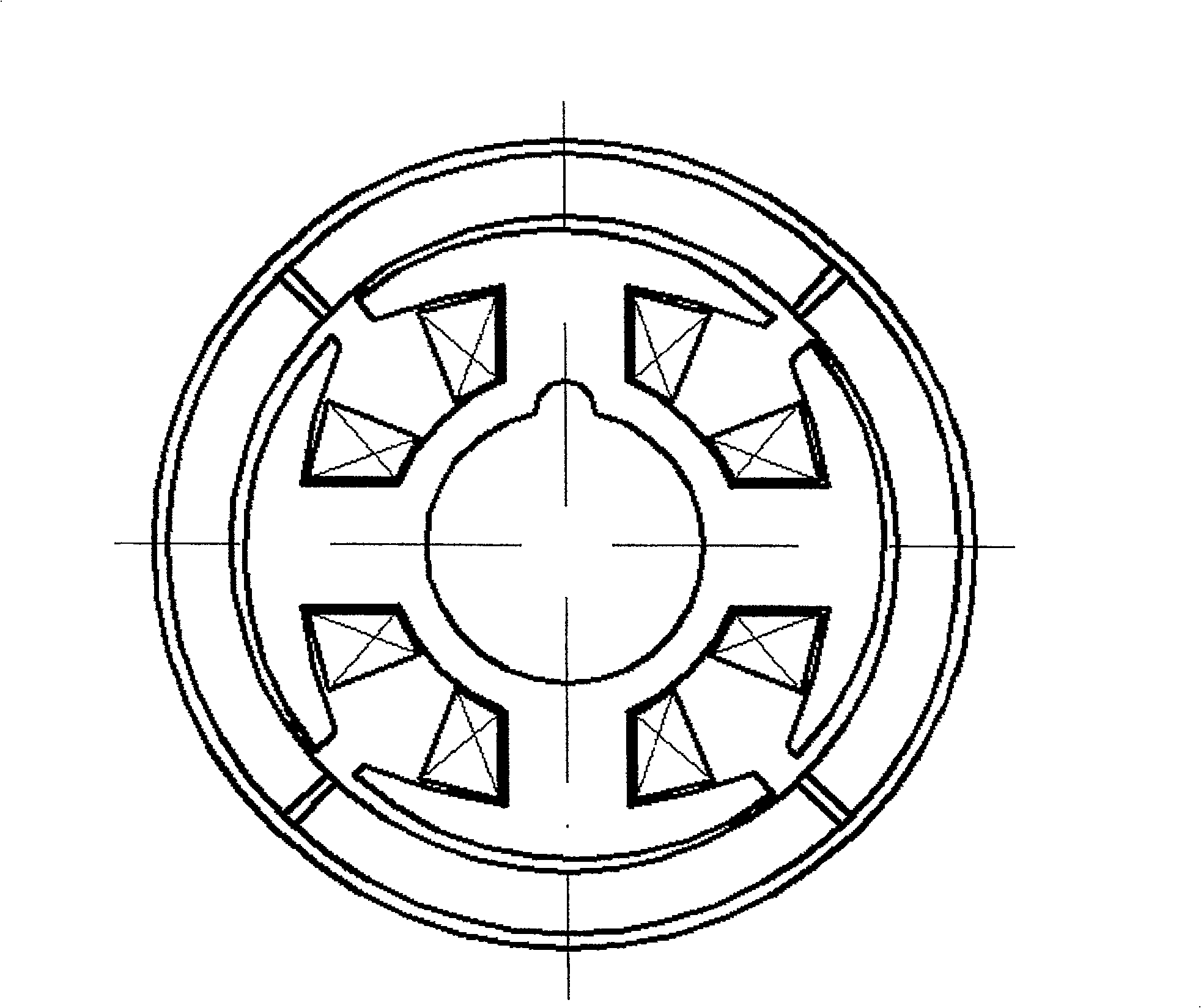

Control method and control circuit for brushless DC motor

A technology of DC motor and control method, which is applied in excitation or armature current control, control system, electronic commutation motor control, etc., can solve the problems of reducing winding installation space and complex motor structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The control method of the unidirectional brushless DC motor proposed by the present invention does not need to use the Hall effect detector. A control circuit is arranged on the H-bridge (H-bridge) of the stator structure of the motor, and based on the so-called motor winding timing Multiplexing (motor winding time-sharing) technology for control. That is to say, using the controller to control the inverter (inverter), when the absolute value of the back electromotive force is extremely large, inject a load current in the motor winding in the same direction as the back electromotive force, so that the motor winding becomes a driving element; and when The absolute value of the back electromotive force is extremely small, so that the motor winding has almost no current and becomes a detection element. At this time, the controller continuously adjusts the time length of the motor winding as the driving element according to the detected back electromotive force information a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com