Method for reducing carbon tetrachloride generation in methane chloride production course by heat chlorination method

A technology of methane chloride and carbon tetrachloride, which is applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve problems such as unclear market prospects of tetrachlorethylene, long construction period of equipment, and large investment of equipment , to achieve the effect of small investment, simple equipment modification and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

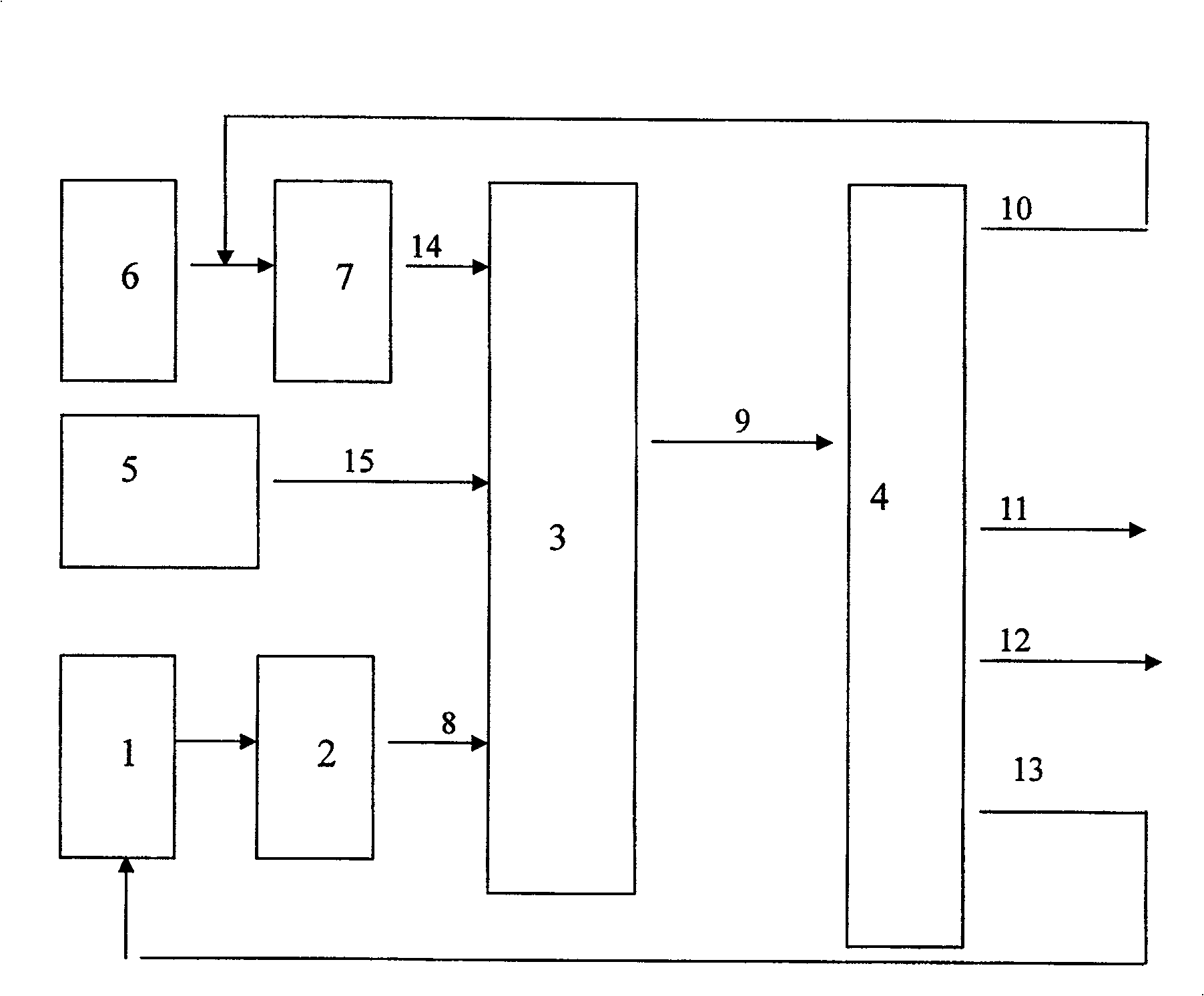

[0019] Embodiment 1: increase one carbon tetrachloride vaporizer (1), carbon tetrachloride superheater (2) and monochloromethane superheater (7) can share one, in normal production process (CH 3 Cl flow 150Nm 3 / h), the carbon tetrachloride is regulated (7.5Nm 3 / h) enter the reactor to participate in the reaction, the reaction temperature is 400 ° C, the residence time is 10 seconds, the reaction is cooled and analyzed after sampling, and the conversion rate of carbon tetrachloride is more than 95%.

Embodiment 2

[0020] Embodiment 2: increase carbon tetrachloride vaporizer (1), each one of carbon tetrachloride superheater (2) in normal production process (CH 3 Cl flow 300Nm 3 / h), carbon tetrachloride is regulated (30Nm 3 / h) enter the superheater to overheat to 270°C, enter the reactor to participate in the reaction, the reaction temperature is 450°C, the residence time is 5 seconds, the reaction is cooled and the sample is analyzed, and the conversion rate of carbon tetrachloride is more than 98%.

Embodiment 3

[0021] Embodiment 3: increase carbon tetrachloride vaporizer (1), each one of carbon tetrachloride superheater (2) in normal production process (CH 3 Cl flow 300Nm 3 / h), carbon tetrachloride is regulated (3Nm 3 / h) enter the superheater to overheat to 270°C, enter the reactor to participate in the reaction, the reaction temperature is 430°C, the residence time is 5 seconds, the reaction is cooled and the sample is analyzed, and the conversion rate of carbon tetrachloride is more than 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com