System and method for removing organic sulfur in coal gas

A technology of organic sulfur and gas, applied in the direction of combustion method, combustible gas purification, combustible gas purification/transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

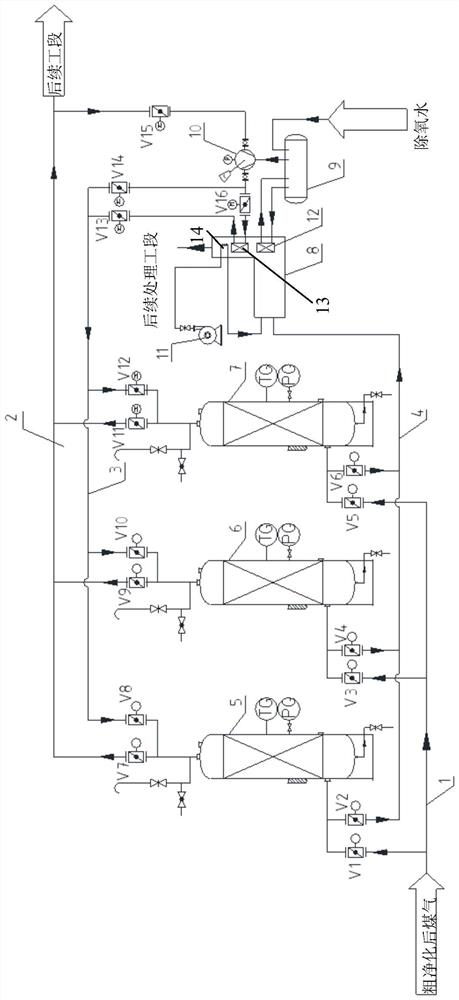

[0096] This embodiment provides a system for removing organic sulfur in gas, wherein the structural diagram of the system for removing organic sulfur in gas is as follows figure 1 shown, from figure 1 As can be seen, the system includes:

[0097] Three desulfurization towers (in the form of 2 for 1 standby), namely the first desulfurization tower 5, the second desulfurization tower 6, the third desulfurization tower 7, the incinerator 8, the regenerative gas blower 10 and the air blower 11;

[0098] The incinerator 8 includes a main combustion chamber and a flue gas discharge chamber, and a gas heating device 13, a steam generating device 12 and an air preheating device 14 are arranged in the flue gas discharge chamber;

[0099] The air inlets of the first desulfurization tower 5, the second desulfurization tower 6, and the third desulfurization tower 7 are respectively connected with the gas inlet main pipe 1 through the gas inlet branch pipes, and the gas inlet branch pipes...

Embodiment 2

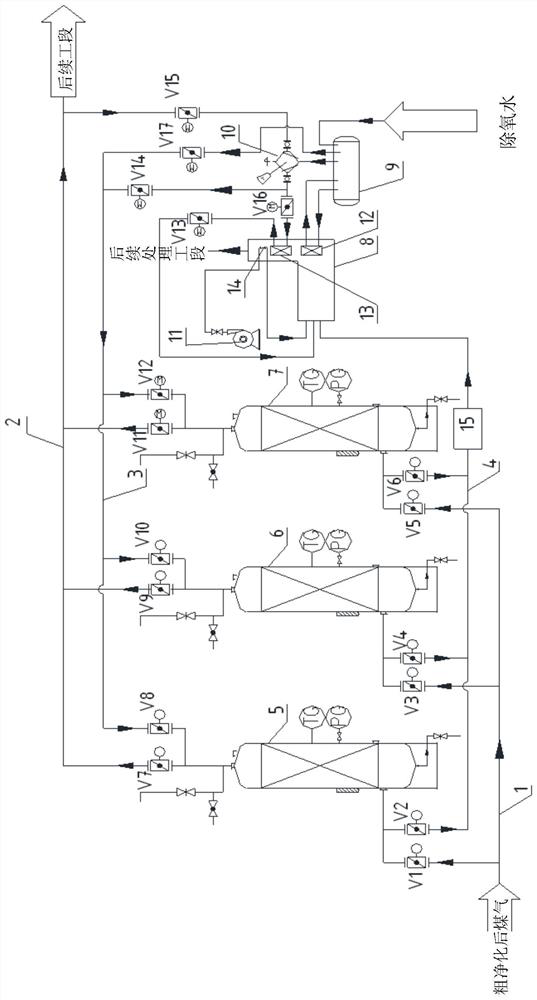

[0109] This embodiment provides a system for removing organic sulfur in gas, wherein the structural diagram of the system for removing organic sulfur in gas is as follows figure 2 shown, from figure 2 As can be seen, the system includes:

[0110] Three desulfurization towers (in the form of 2 for 1 standby), namely the first desulfurization tower 5, the second desulfurization tower 6, the third desulfurization tower 7, the incinerator 8, the regenerative gas blower 10 and the air blower 11;

[0111] The incinerator 8 includes a main combustion chamber and a flue gas discharge chamber, which is provided with a gas heating device, a steam generating device 12 and an air preheating device;

[0112] The air inlets of the first desulfurization tower 5, the second desulfurization tower 6, and the third desulfurization tower 7 are respectively connected with the gas inlet main pipe 1 through the gas inlet branch pipes, and the gas inlet branch pipes are all provided with cut-off v...

Embodiment 3

[0124] This embodiment provides a method for removing organic sulfur in gas, wherein the method for removing organic sulfur in gas utilizes the system for removing organic sulfur in gas provided in Example 1, which includes the following steps:

[0125] The coal gas used in this embodiment is blast furnace gas after rough purification, and the total sulfur in the gas is less than 300mg / m 3 Greater than or equal to 100mg / m 3 , gas pressure is 12KPa, dust content is less than 10mg / m 3 , gas temperature is 80℃, flow rate is 300000Nm 3 / h;

[0126] Open the first cut-off valve V1, the third cut-off valve V3, the seventh cut-off valve V7, and the ninth cut-off valve V9, and make the eighth cut-off valve V8, the tenth cut-off valve V10, the second cut-off valve V2, and the fourth cut-off valve V4 Wait until other valves are closed;

[0127] The blast furnace gas enters the first desulfurization tower 5 and the second desulfurization tower 6 respectively through the gas inlet mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com