A noble metal-carbon nanotube three-dimensional porous composite and its preparation method and application

A carbon nanotube, three-dimensional porous technology, applied in the direction of alkali metal compounds, alkali metal oxides/hydroxides, separation methods, etc., can solve the problems of non-combustible coal soot separation, affecting material adsorption performance, uneven loading, etc. Achieve the effects of easy separation of coal-fired soot, increase of adsorption capacity, and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] TiO 2 The method for preparing silver-carbon nanotube three-dimensional porous composite as connecting layer comprises the following steps:

[0064] 1) carbon nanotube sponge is placed in the ethanol solution of tetrabutyl titanate, the volume ratio of tetrabutyl titanate and ethanol is 1:7, the mass ratio of carbon nanotube sponge and tetrabutyl titanate is 1: 100, shake on a shaker for 1 hour, so that tetrabutyl titanate is evenly adsorbed on the surface of the carbon nanotube sponge;

[0065] 2) Transfer the carbon nanotube sponge adsorbed with tetrabutyl titanate to water for ultrasonication, the volume ratio of carbon nanotube sponge to water is 1:100, and the ultrasonic time is 40min, so that tetrabutyl titanate is hydrolyzed into TiO 2 Wrapped on the surface of carbon nanotube sponge to form TiO 2 - Carbon nanotube sponge core-shell structure;

[0066] 3) adding ethanol dropwise to the three-dimensional composite, and then compressing and cleaning, repeating t...

Embodiment 2

[0073] TiO 2 The method for preparing a gold-carbon nanotube three-dimensional porous composite as a connecting layer comprises the following steps:

[0074]1) carbon nanotube sponge is placed in the ethanol solution of tetrabutyl titanate, the volume ratio of tetrabutyl titanate and ethanol is 1:7, the mass ratio of carbon nanotube sponge and tetrabutyl titanate is 1: 100, shake on a shaker for 10 minutes, so that tetrabutyl titanate is evenly adsorbed on the surface of carbon nanotube sponge;

[0075] 2) Transfer the carbon nanotube sponge adsorbed with tetrabutyl titanate to water for ultrasonication, the volume ratio of carbon nanotube sponge to water is 1:1000, and the ultrasonic time is 40min, so that tetrabutyl titanate is hydrolyzed into TiO 2 Wrapped on the surface of carbon nanotube sponge to form TiO 2 - Carbon nanotube sponge core-shell structure;

[0076] 3) adding ethanol dropwise to the three-dimensional composite, and then compressing and cleaning, repeating...

Embodiment 3

[0083] The method for preparing silver-carbon nanotube three-dimensional porous composite with carbon as connecting layer comprises the following steps:

[0084] 1) Put the carbon nanotube sponge in 1M glucose aqueous solution, place the carbon nanotube sponge and the glucose aqueous solution in a reaction kettle at 190°C for 4 hours, so that the surface of the carbon nanotube sponge is evenly coated with a layer of carbon as a connecting layer;

[0085] 2) Immerse the carbon nanotube sponge with a carbon connection layer on the surface into 1M AgNO 3 Ag adsorption in solution for 24h + , and dry;

[0086] 3) Adsorbed Ag + The carbon nanotube sponge was heated at 550 °C under the protection of inert gas to make AgNO 3 Decompose to obtain Ag-carbon nanotube three-dimensional porous composite.

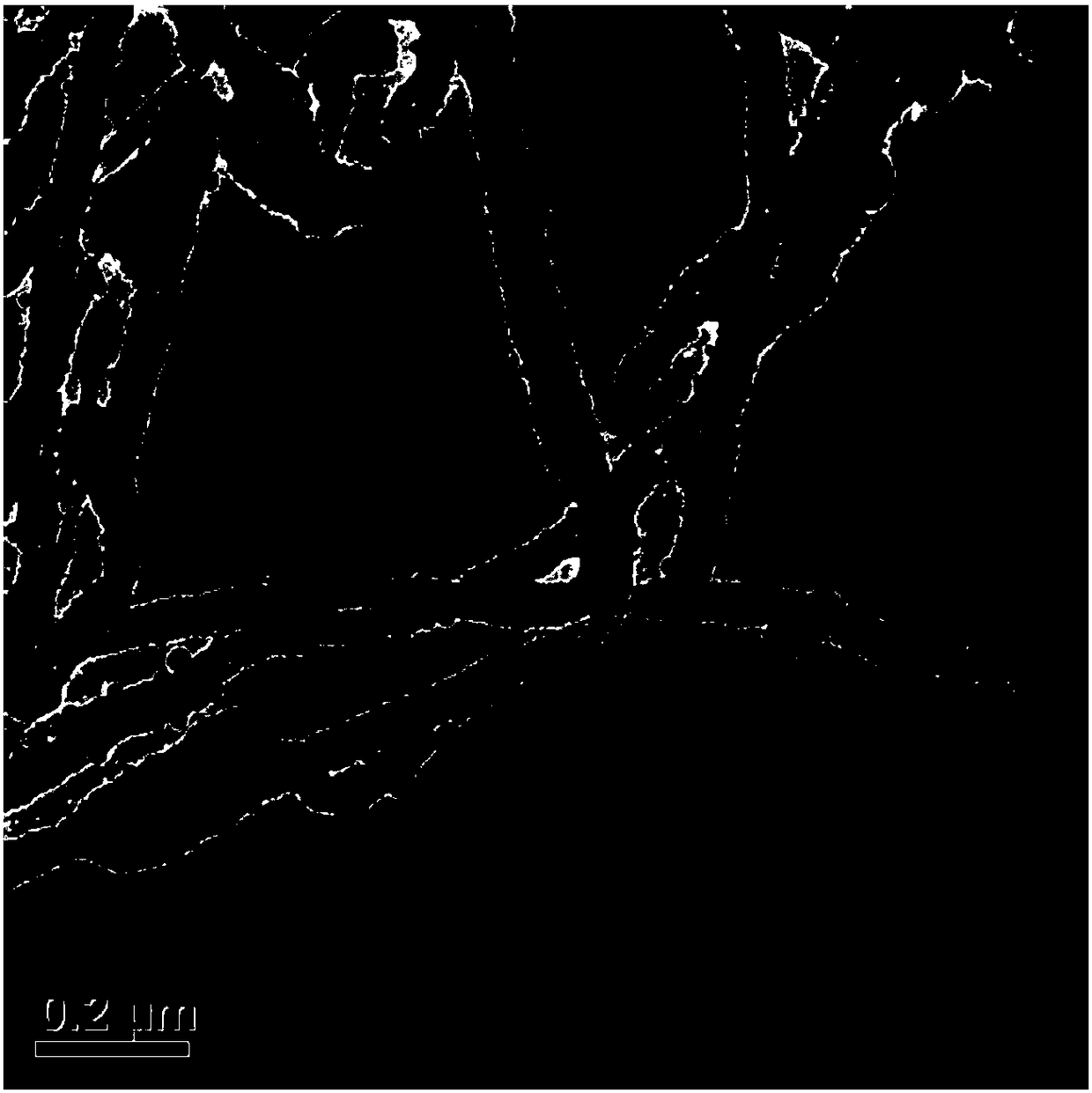

[0087] Observed by a scanning electron microscope (model Hitachi S4800 FESEM), the length of the carbon nanotube sponge is tens to hundreds of microns, and the silver nanoparticles a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com