High-integration integrated low-temperature stop valve with one-way function

A one-way function, globe valve technology, applied in functional valve type, lift valve, valve details, etc., can solve the problems of easy interference, poor boosting effect, complicated booster pipeline structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

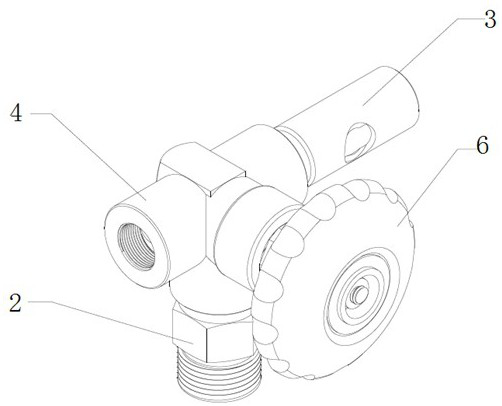

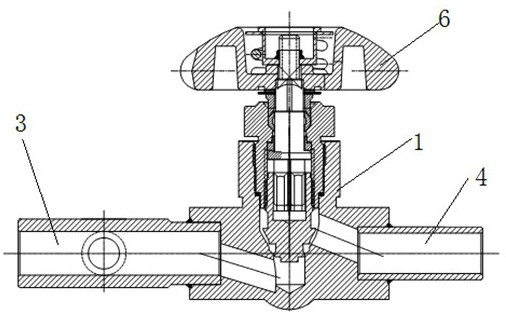

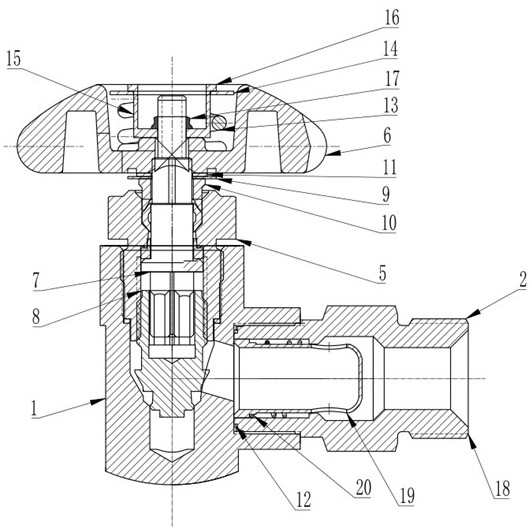

[0019] As shown in the figure: the technical solution of this embodiment is: a highly integrated integrated cryogenic cut-off valve with one-way function, including the valve body 1 of the cut-off valve, the one-way valve 2, the first connecting pipe 3, the second Connecting pipe 4, valve cover 5 and hand wheel 6 are all highly integrated on the valve body 1, and the one-way valve 2 is connected to the valve body 1 through a straight thread to realize the shortest gas cylinder connecting pipeline Minimize the use of space and space, reduce the occupation of the valve space at the root of the vehicle bottle while meeting the regulatory requirements, simplify the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com