A kind of method adopting polyethylene glycol/alkali method to degrade brominated flame retardant

A brominated flame retardant and polyethylene glycol technology, which is applied in the field of degrading brominated flame retardants by polyethylene glycol/alkali method, and achieves the effects of mild reaction conditions, easy degradation treatment and high treatment concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

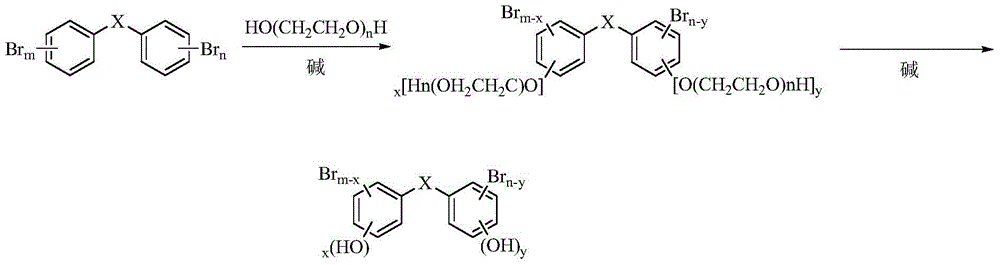

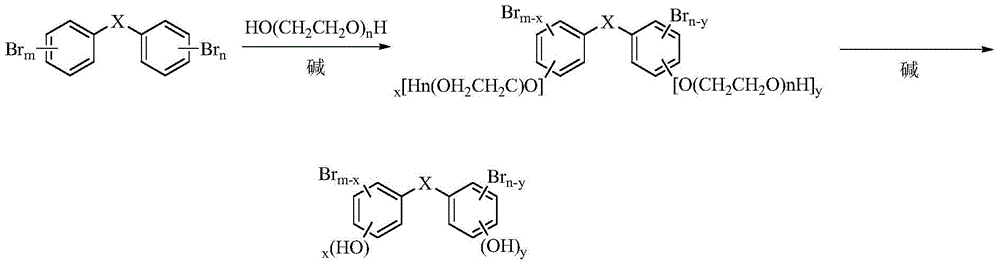

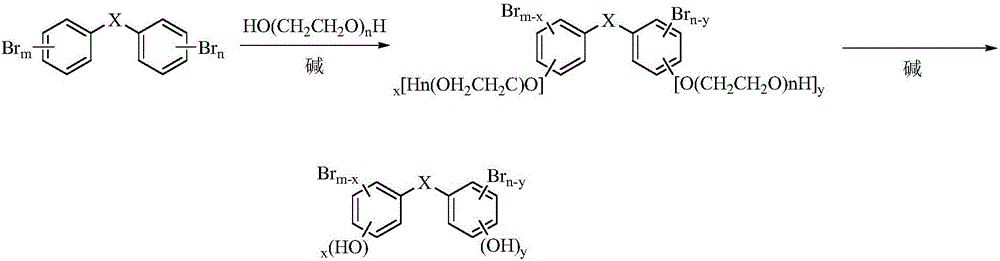

Method used

Image

Examples

Embodiment 1 10

[0019] Example 1 Degradation of decabromodiphenyl ether under the action of polyethylene glycol with different degrees of polymerization

[0020] Weigh 5.0g (5.2mmol) of decabromodiphenyl ether, add it to a 100ml three-neck flask, add polyethylene glycols with different degrees of polymerization (PEG-200, PEG-400, PEG-600, PEG-800 or PEG-1000 ) 50ml, and KOH3.5g (62.5mmol), the auxiliary agent is 5.0ml of ethylene glycol, the reaction temperature is controlled at 160°C under stirring at a speed of 300r / min, and the reaction pressure is normal pressure, according to the effect of polyethylene glycol The debromination rate of decabromodiphenyl ether is different, and the reaction time is also different (the reaction time starts from the reaction temperature rising to the set temperature). The specific debromination results are shown in Table 1 [debromination rate=n(Br) 溶液 / n(Br) 总 ].

[0021] Table 1. Degradation of decabromodiphenyl ether under the action of polyethylene glyc...

Embodiment 2

[0023] The influence of embodiment 2 additives on debrominated degradation of decabromodiphenyl ether in polyethylene glycol / KOH

[0024] Weigh 5.0g (5.2mmol) of decabromodiphenyl ether, add it to a 100ml three-necked flask, add 50ml of polyethylene glycol-600 (PEG-600), and KOH3.5g (62.5mmol), additives (ethylene glycol Alcohol, propylene glycol or glycerol) 5.0ml, the reaction temperature is controlled at 160°C under stirring at a speed of 300r / min, and the reaction pressure is normal pressure. According to the different debromination rates of decabromodiphenyl ether under the action of different additives, The reaction time is also different (the reaction time starts from the reaction temperature rising to the set temperature), and the specific debromination results are shown in Table 2 [debromination rate=n(Br) 溶液 / n(Br) 总 ].

[0025] Table 2. Effects of additives on the debromination degradation of decabromodiphenyl ether in polyethylene glycol / KOH

[0026] Au...

Embodiment 3

[0027] Embodiment 3 The influence of temperature on the debromination degradation of decabromodiphenyl ether in polyethylene glycol / KOH

[0028] Weigh 5.0g (5.2mmol) of decabromodiphenyl ether, add it to a 100ml three-necked flask, add 50ml of polyethylene glycol-600 (PEG-600), and KOH3.5g (62.5mmol), the auxiliary agent ethylene glycol 5.0ml, the reaction temperature is controlled under stirring at a rotating speed of 300r / min, and the reaction pressure is normal pressure. According to the different debromination rates of decabromodiphenyl ether at different temperatures, the reaction time is also different (reaction time increases from reaction temperature to start timing when the set temperature is reached), the specific debromination results are shown in Table 3 [debromination rate=n(Br) 溶液 / n(Br) 总 ].

[0029] Table 3. Effect of temperature on debromination degradation of decabromodiphenyl ether in polyethylene glycol / KOH

[0030] Auxiliary

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com