Preparation method of novel biodegradable wrapping film

A biodegradable and stretch film technology, which is applied in the field of packaging film, can solve the problems of being susceptible to corrosion damage, shortening the service life of stretch film, and low strength in use, and achieves easy degradation, reduced raw material costs, good strength and corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

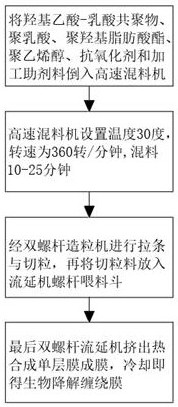

[0049] see figure 1 , the present invention provides a method for preparing a novel biodegradable stretch film. The biodegradable stretch film is mainly prepared by combining glycolic acid-lactic acid copolymer with polylactic acid, polyhydroxyalkanoate and polyvinyl alcohol;

[0050] Its biodegradable stretch film is prepared from the following raw materials in parts by weight:

[0051] Glycolic acid-lactic acid copolymer: 70-95 parts

[0052] Polylactic acid: 5-10 parts

[0053] Polyhydroxyalkanoate: 2-16 parts

[0054] Polyvinyl alcohol: 1-5 parts

[0055] Antioxidant 0.1-0.6 parts

[0056] Processing aid 0.2-1.2 parts.

[0057] It is characterized in that the above materials are added in different ratios to prepare A group materials, B group materials, and C group materials, and the specific ratios are as follows:

Embodiment 1

[0059] Group A

[0060] Glycolic acid-lactic acid copolymer: 70 parts

[0061] Polylactic acid: 10 parts

[0062] Polyhydroxyalkanoate: 16 parts

[0063] Polyvinyl alcohol: 2.5 parts

[0064] Antioxidant 0.5 parts

[0065] 1 part processing aid

[0066] In this example, 70 parts of glycolic acid-lactic acid copolymer, 10 parts of polylactic acid, 16 parts of polyhydroxyalkanoate, 2.5 parts of polyvinyl alcohol, 0.5 parts of antioxidant and 1 part of processing aid were poured into High-speed mixer, set the temperature at 30 degrees, the speed is 360 rpm, mix the material for 10-25 minutes, then go through the twin-screw granulator for stretching and pelletizing, and then put the pelletized material into the first casting machine The screw feeds the hopper, and finally the twin-screw casting machine extrudes the thermally synthesized single-layer film to form a film, and then cools to obtain a biodegradable stretch film.

Embodiment 2

[0068] Group B material

[0069] Glycolic acid-lactic acid copolymer: 80 parts

[0070] Polylactic acid: 6 parts

[0071] Polyhydroxyalkanoates: 11 parts

[0072] Polyvinyl alcohol: 1.5 parts

[0073] Antioxidant 0.5 parts

[0074] 1 part processing aid

[0075] In this example, glycolic acid-lactic acid copolymer: 80 parts, polylactic acid: 6 parts, polyhydroxyalkanoate: 11 parts, polyvinyl alcohol: 1.5 parts, antioxidant 0.5 part and processing aid 1 part were poured into High-speed mixer, set the temperature at 30 degrees, the speed is 360 rpm, mix the material for 10-25 minutes, then go through the twin-screw granulator for stretching and pelletizing, and then put the pelletized material into the first casting machine The screw feeds the hopper, and finally the twin-screw casting machine extrudes the thermally synthesized single-layer film to form a film, and then cools to obtain a biodegradable stretch film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com