Sand control well completion structure capable of easily pulling out underground sand control pipe column

A technology of sand control pipe and well structure, applied in the direction of wellbore/well components, drill pipe, casing, etc., can solve problems such as difficulties, deflection of sand control string, poor isolation effect, etc., and achieve easy maintenance and use, Easy to put in and pull out, not easy to deform and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

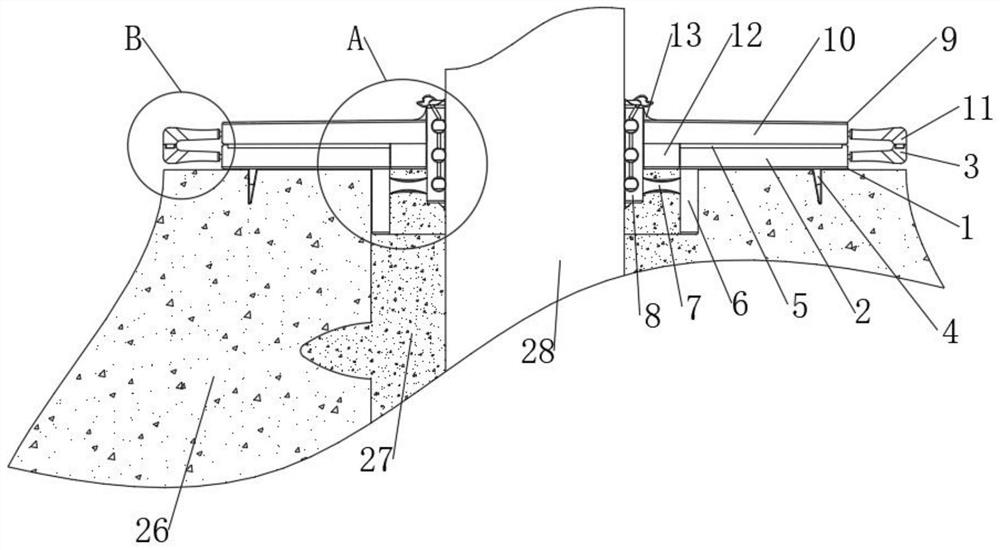

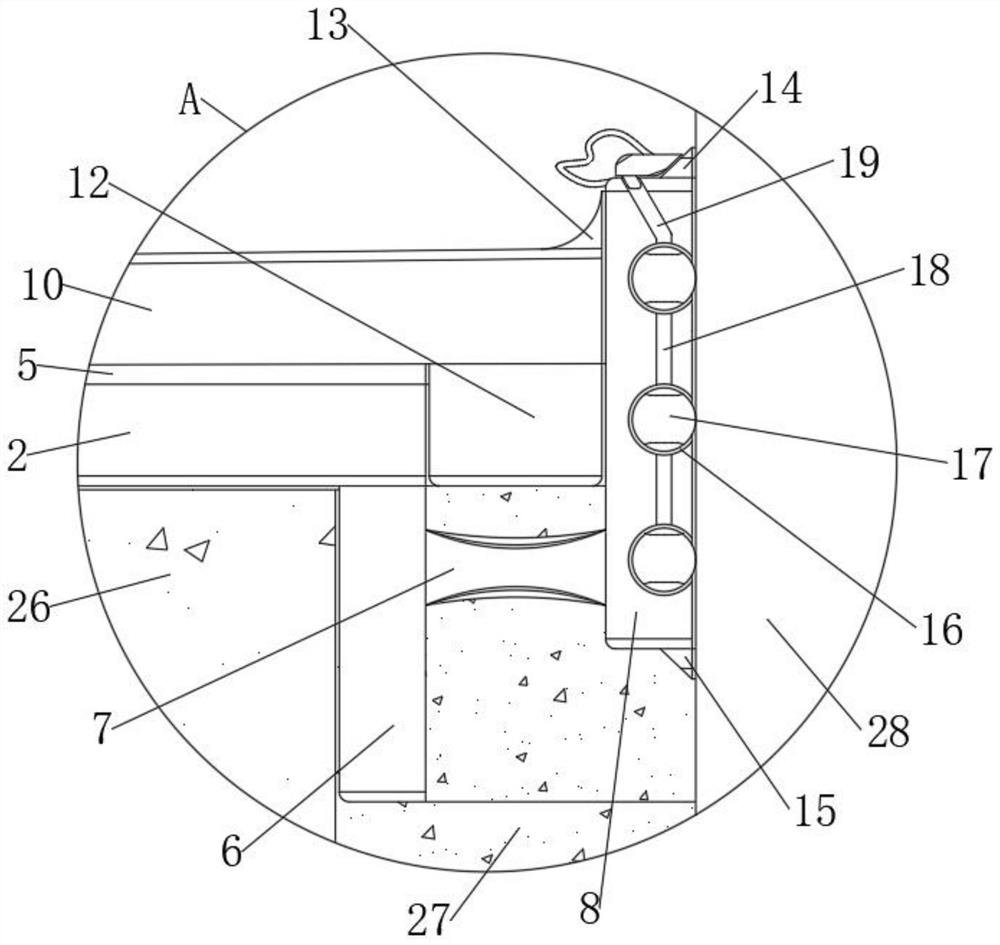

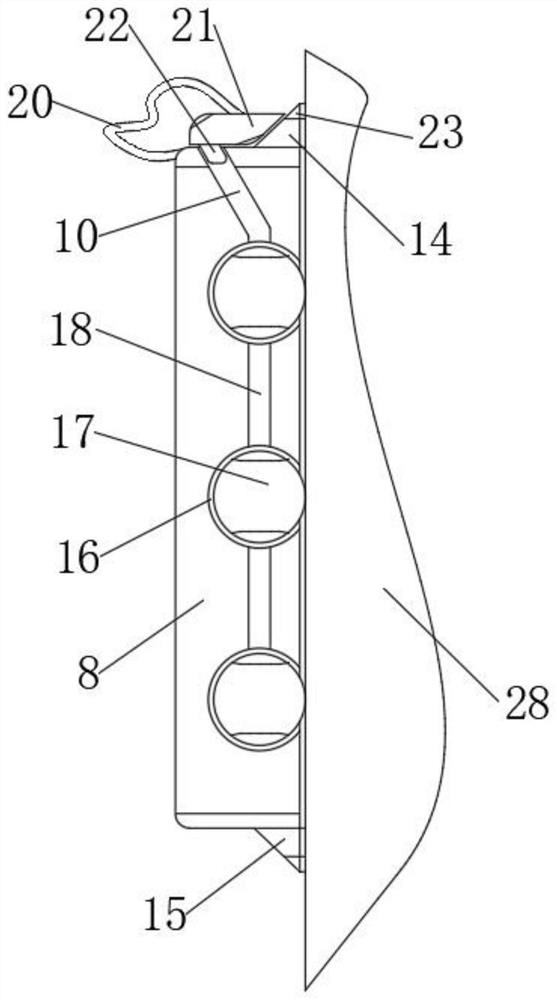

[0036] See Figure 1-12 The present invention provides the following technical solution: a sand-absorbing well completion structure of an easy-to-out sand sand-absorbing tube, including a loose sandstone formation 26, a spacer filling layer 27, and a sand-absorbing tube 28, and the interior of the loose sandstone formation 26 is opened. The inside of the wellhead is provided with a sand-absorbing tube 28, and the sandstone portion is disposed in the inside of the wellhead, wherein the discharging layer 27 is provided, wherein the zone sandstone formation 26, the isolator filler layer 27 and the sand-absorbing pillar 28 are now If there is a technology, please refer to the disclosure of the disclosure of the disclosure of the disclosure of the Chinese invention patent publication of CN20132079528.0, which is no longer described herein.

[0037] Refer figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, the upper end of the well...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com