Radiotherapy compensation film manufacturing mold

A compensation film and mold technology, which is applied in the field of medical devices, can solve the problems of inconvenient adjustment and control of the thickness and density of the radiotherapy compensation film, troublesome production process, and low cost, so as to reduce production trouble, have high practicability, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

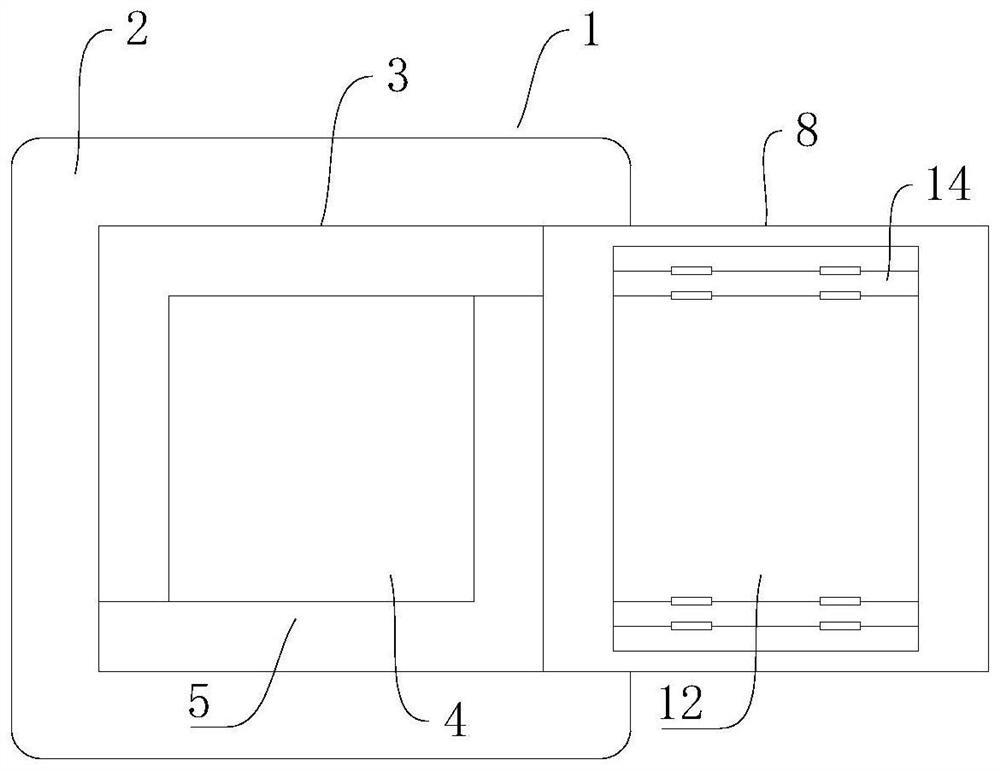

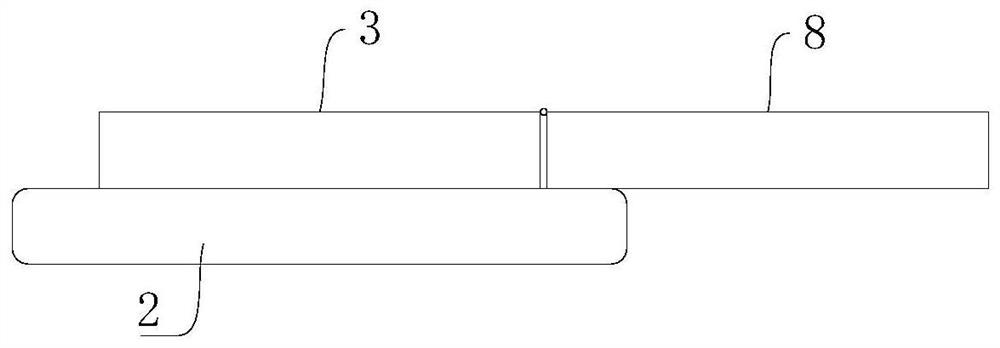

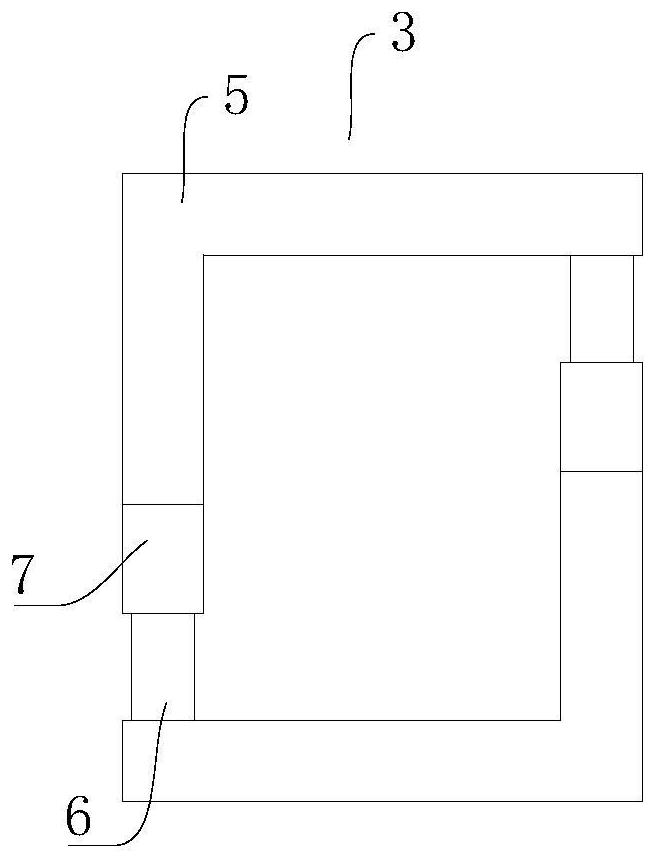

[0041] Please refer to Figure 1-Figure 5 , figure 1 It is a connection diagram of the device main body 1 and the end cover 8 in the embodiment of the present invention; figure 2 It is a structural diagram of another perspective after the device main body 1 is connected to the end cover 8 in the embodiment of the present invention; image 3 It is a schematic diagram of the connection of the physical frame 3 in the embodiment of the present invention; Figure 4 It is a schematic structural diagram of another state of the body frame 3 in the embodiment of the present invention; Figure 5 It is a structural schematic diagram of the pressing assembly in the embodiment of the present invention.

[0042] The present embodiment provides a mold for making radiotherapy compensation film, which includes a device main body 1. The device main body 1 includes a base plate 2 and a body frame 3. Then it is a closed frame structure, its shape can be circular, also can be square etc., do ...

Embodiment 2

[0049] Please refer to Figure 1-Figure 4 , in some embodiments of the present invention, the above-mentioned physical frame 3 includes two identically arranged connecting frames 5, that is image 3 and Figure 4 Shown connecting frame 5 structure, and in the present embodiment, the structure of body frame 3 is a rectangular frame body, so, connecting frame 5 just constitutes the 7-shaped frame body of this rectangular frame body, and body frame 3 overall structure changes , the mechanism of the connecting frame 5 will also change accordingly; the two connecting frames 5 are slidably connected with the bottom plate 2 respectively.

[0050] One end of the two connecting frames 5 is respectively provided with a telescopic rod 6 slidingly fitted with itself, and the other end of the telescopic rod 6 is fixedly connected with the other connecting frame 5 . Such as image 3 and Figure 4 As shown, that is, one end of the telescopic rod 6 is located in the inside of the connecti...

Embodiment 3

[0056] In some embodiments of the present invention, dovetail blocks are provided at the bottom ends of the above-mentioned two connecting frames 5 , and dovetail grooves used in conjunction with the dovetail blocks are provided on the upper surface of the bottom plate 2 .

[0057] The setting of the dovetail groove and the dovetail block is a way to realize the sliding connection between the connecting frame 5 and the bottom plate 2, and of course, there are other ways to realize it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com