Preparation method of modified collagen fiber material capable of efficiently capturing iodine vapor

A technology of collagen fibers and fibrils, which is applied in the field of preparation of modified collagen fibers to efficiently capture iodine vapor materials, which can solve the problems of low recycling rate, difficult post-processing, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a material for efficiently capturing iodine vapor by modified collagen fibers, comprising the following steps:

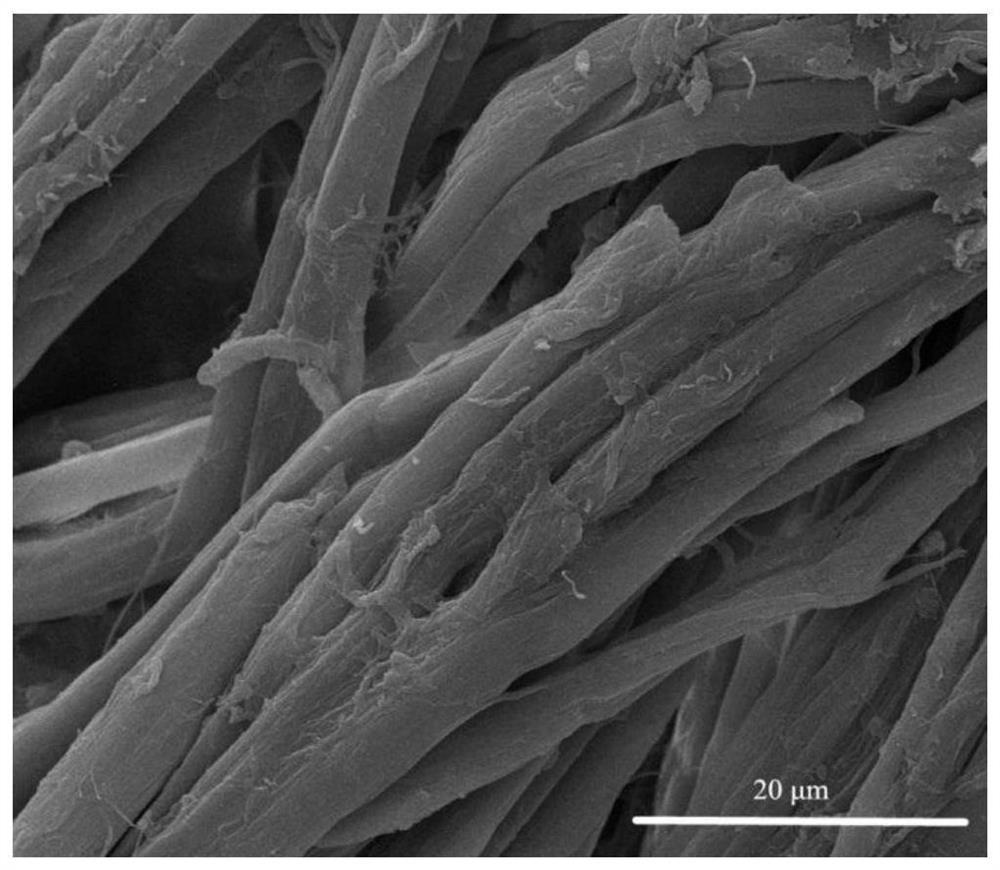

[0044] Step 1. After cleaning, alkali treatment, dehydration and other treatments according to conventional methods, the untanned animal skins are pulverized by a pulverizer to obtain granular collagen fibers with a particle size of 50 mesh, added to deionized water, and cleaned in an ultrasonic cleaning machine. Ultrasonic cleaning for 5 hours, washing to neutrality, drying in an oven after filtration; wherein the ultrasonic cleaning temperature and oven temperature are controlled at 40°C;

[0045] Step 2, pulverize the cleaned collagen fibers in a pulverizer, and the particle size is 40 mesh; get 10g of collagen fibers and 5g of sodium hydroxide solid alkali modifier to grind and mix evenly, and put them in a tube furnace where the ambient gas is nitrogen. Calcined at 150°C for 2h, then cooled to room temperature;

[0046]Step 3: Rin...

Embodiment 2

[0048] A method for preparing a material for efficiently capturing iodine vapor by modified collagen fibers, comprising the following steps:

[0049] Step 1. After cleaning, alkali treatment, dehydration and other treatments according to conventional methods, the untanned animal skins are pulverized by a pulverizer to obtain granular collagen fibers with a particle size of 50 mesh, added to deionized water, and cleaned in an ultrasonic cleaning machine. Ultrasonic cleaning for 5 hours, washing to neutrality, drying in an oven after filtration; the ultrasonic cleaning temperature and oven temperature are controlled at 45°C;

[0050] Step 2, pulverize the cleaned collagen fiber in a pulverizer, the particle size is 60 mesh; get 10g collagen fiber and 5g potassium hydroxide solid alkali modifier to grind and mix evenly, and place in a tube furnace where the ambient gas is nitrogen. Calcined at 180°C for 5h, then cooled to room temperature;

[0051] Step 3. Rinse the calcined mat...

Embodiment 3

[0053] A method for preparing a material for efficiently capturing iodine vapor by modified collagen fibers, comprising the following steps:

[0054] Step 1. After cleaning, alkali treatment, dehydration and other treatments according to the conventional method, the untanned animal skin is pulverized by a pulverizer to obtain granular collagen fibers with a particle size of 60 mesh, added to deionized water, and cleaned in an ultrasonic cleaner. Ultrasonic cleaning for 5 hours, washing to neutrality, drying in an oven after filtration; wherein the ultrasonic cleaning temperature and oven temperature are controlled at 50°C;

[0055] Step 2, pulverize the cleaned collagen fiber in a pulverizer, the particle size is 80 mesh; take 10g of collagen fiber and 10g of potassium hydroxide and sodium hydroxide and mix (weight ratio 1:1) Solid alkali modifier grinds and mixes evenly , calcined at 220°C for 5h in a tube furnace with nitrogen as the ambient gas, and cooled to room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com