A kind of preparation method of superhydrophobic metal matrix composite coating

A metal-based composite, super-hydrophobic technology, applied in coatings, electrolytic coatings, etc., can solve the problems of great harm to the environment and human health, affect the practicability, and large porosity of the super-hydrophobic metal-based composite coating, so as to improve the density. The effect of smoothness, ease of realization, and compact and flat coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

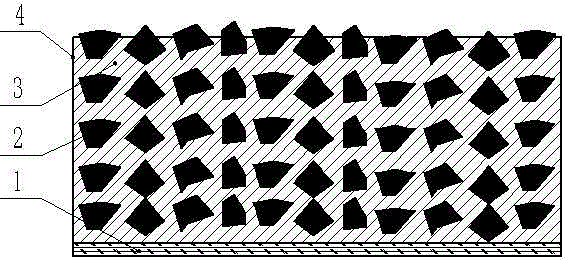

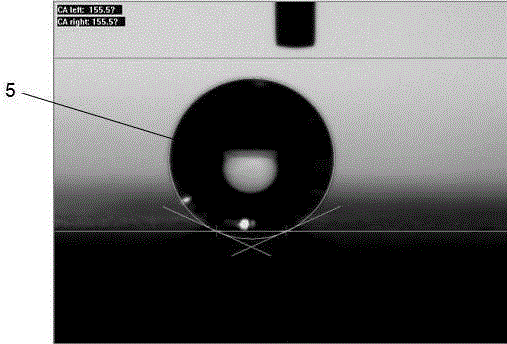

[0030] Combine below figure 1 and figure 2 The specific implementation process of the present invention - "a method for preparing a super-hydrophobic metal-based composite coating" will be further described.

[0031] (a) Take 100g of polytetrafluoroethylene particles 2 with an average particle size of 0.2 micron (surface area is about 15m 2 / g), 7.5g of cetyltrimethylammonium bromide (CTAB), 0.75g of non-ionic fluorocarbon surfactant FC-4430 were added to 100ml of deionized water, and stirred vigorously at room temperature for 120 minutes to form a water-based suspension.

[0032] (b) Add 100ml of the water-based suspension to the nickel electroplating solution and stir vigorously for 60 minutes to prepare 2L of mixed electrolyte. The composition of nickel electroplating solution is: NiSO 4 ·6H 2 O200g / L, NiCl 2 ·6H 2 O20g / L, HBO 3 30g / L.

[0033] (c) Using a stainless steel sheet as the cathode substrate 1 and an electrolytic nickel plate as the anode, perform elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com