Electric connector and assembling method thereof

A technology of electrical connectors and assembly methods, which is applied in the direction of two-part connection devices, connections, circuit/collector components, etc., can solve the problems of inability to transmit data signals and meet the needs of diversified connector functions, and achieve easy The effect of manufacturing, good signal transmission capability, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

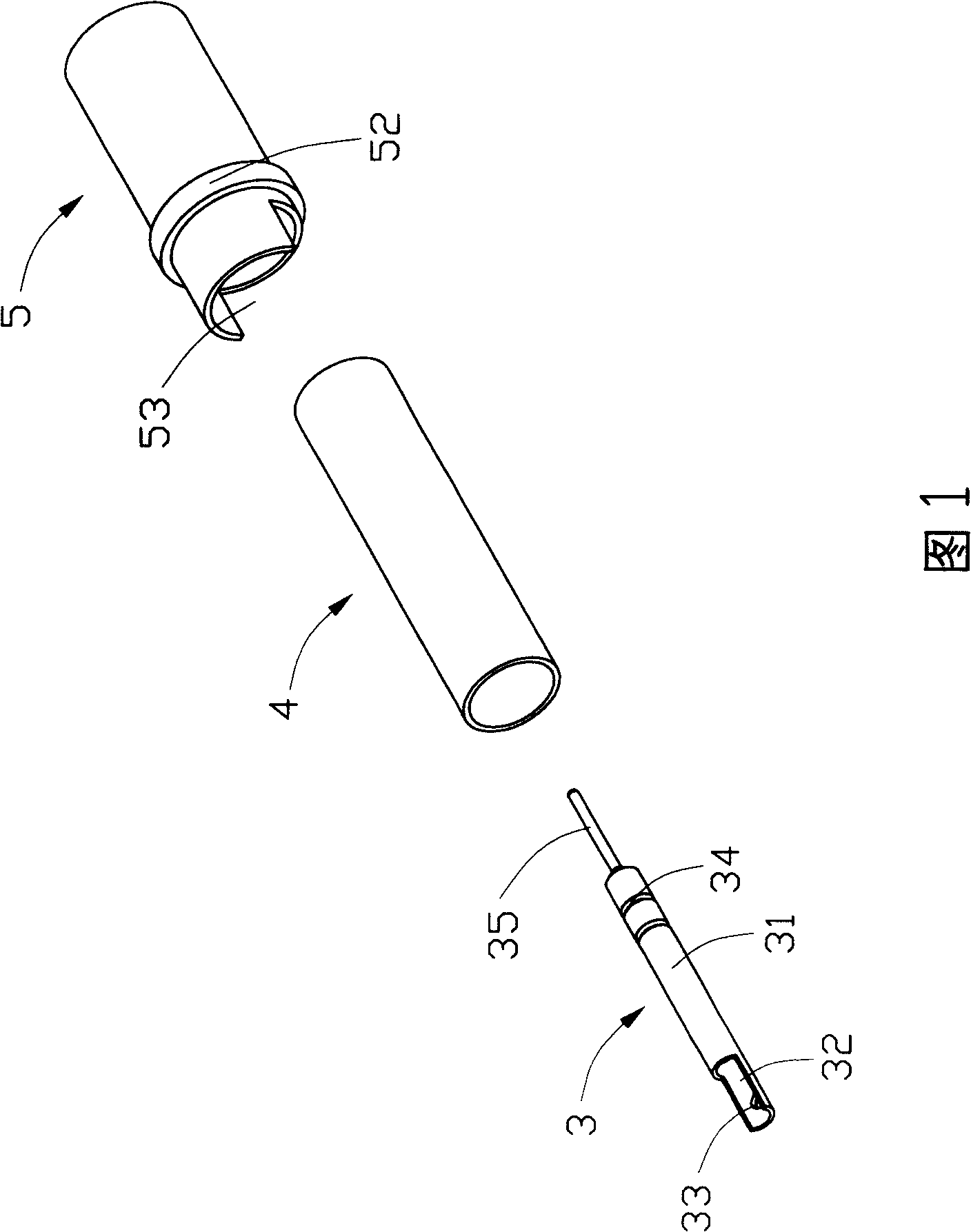

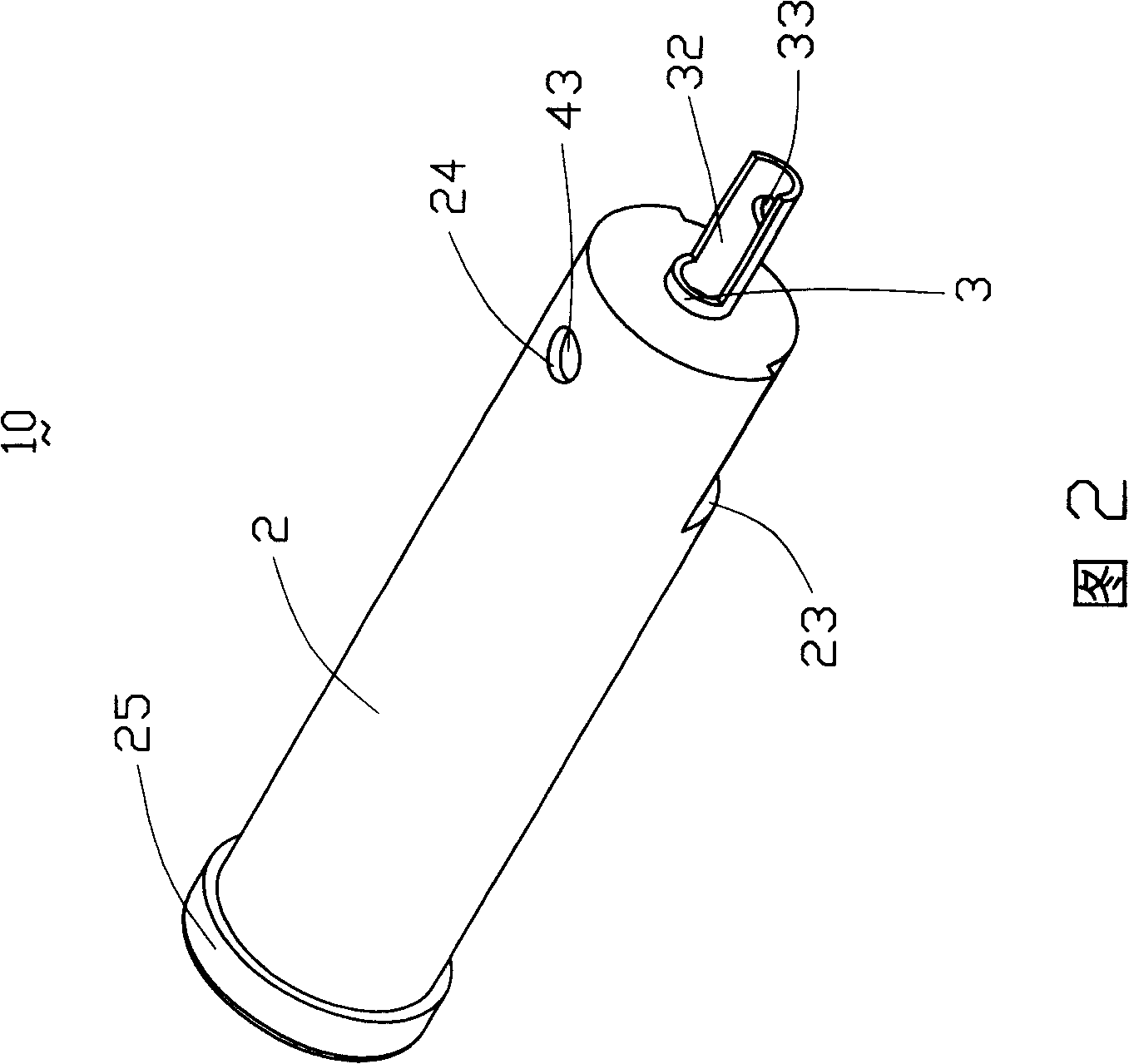

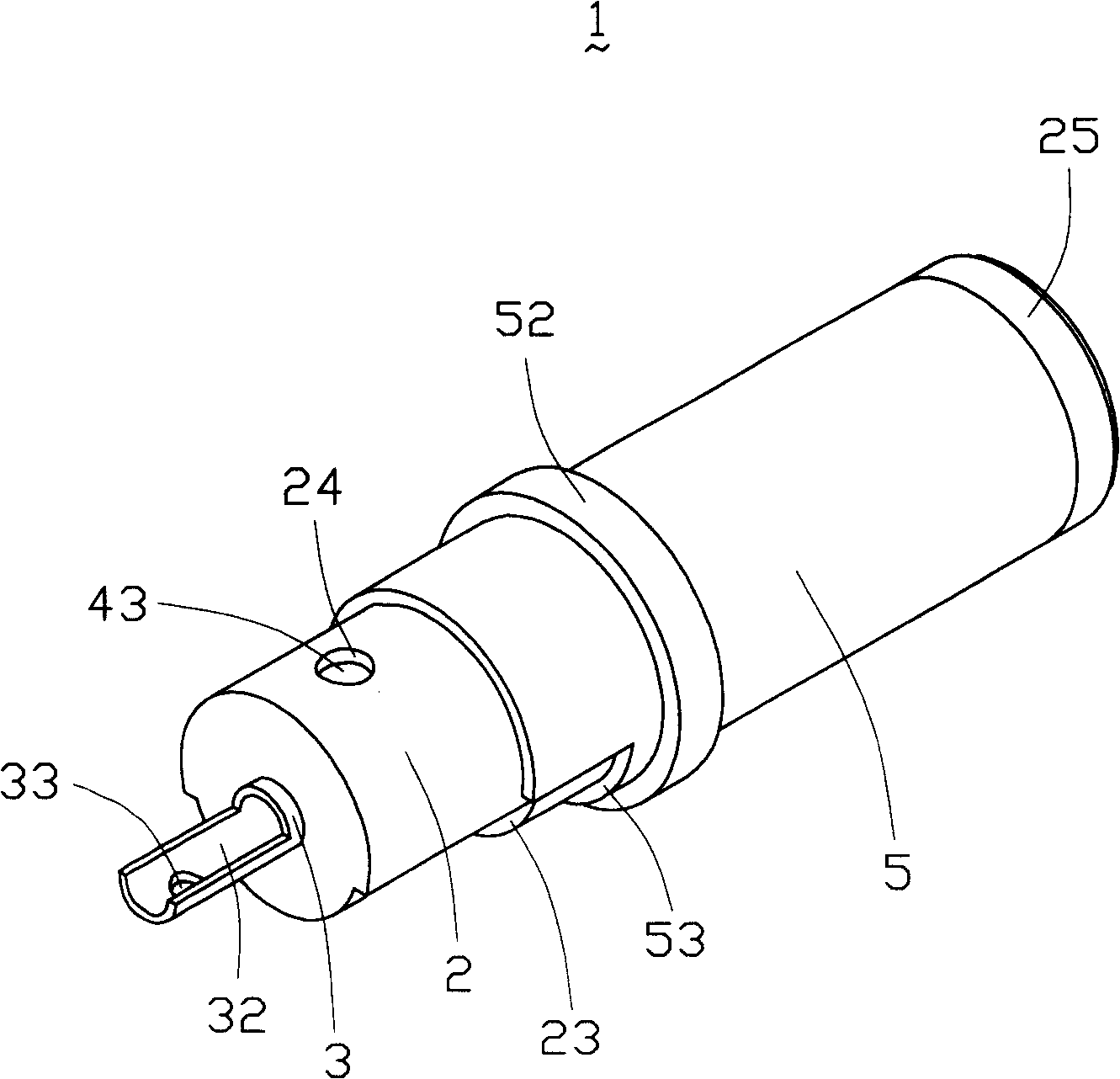

[0016] Please refer to FIG. 1 to FIG. 2 , the assembling method of the electrical connector 1 of the present invention includes an injection molding step and a casing assembling step. The injection molding step is to fix the pre-provided central terminal 3 and metal tube 4 in the mold cavity, and then inject molten plastic into the mold cavity to solidify the plastic to combine the central terminal, metal tube and plastic together to form The signal module 10 ; the step of assembling the shell is to set the pre-provided metal sleeve 5 on the signal module 10 formed by the above injection molding step.

[0017] Please refer to FIG. 1 , the pre-provided central terminal 3 is roughly columnar, and includes a base 31 , a docking portion 35 extending forward from one end of the base 31 , and a connecting portion 32 extending backward from the other end of the base 31 . Wherein, the base portion 31 is provided with an annular groove 34 , the connection portion 32 is in the shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com