A kind of multilayer pcb circuit board

A PCB circuit board and substrate technology, which is applied in the direction of circuit devices, printed circuits, printed circuits, etc., can solve the problems of poor performance of multi-layer PCB circuit boards, degradation of electronic product performance, and difficult-to-stack structure symmetry, etc., to achieve electromagnetic compatibility performance Excellent, balanced performance, and performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

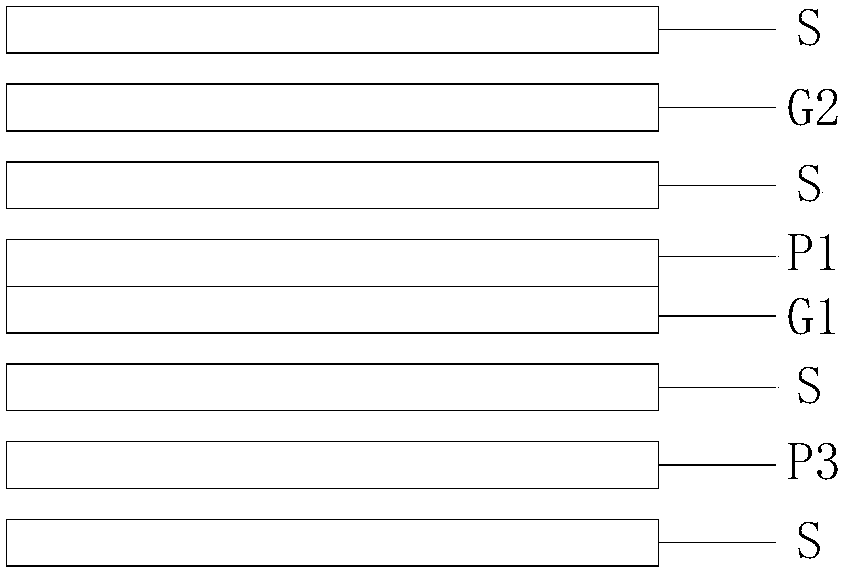

[0029] Such as figure 1 As shown, the total number of layers of the PCB circuit board is 8 layers, and from top to bottom are the signal layer S, the second ground layer G2, the signal layer S, the first power layer P1, the first ground layer G1, the signal layer S, the third power layer P3 and the signal layer S.

[0030] The thickness of the PCB circuit board is 1.2-2.4mm.

Embodiment 2

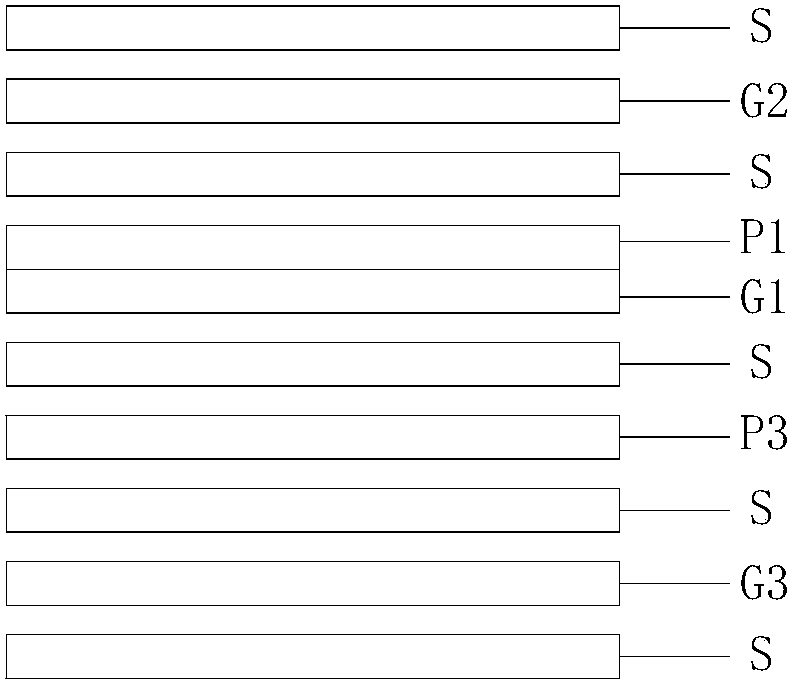

[0032] Such as figure 2 As shown, the total number of layers of the PCB circuit board is 10 layers, which are the signal layer S, the second ground layer G2, the signal layer S, the first power layer P1, the first ground layer G1, and the signal layer from top to bottom. S, the third power layer P3, the signal layer S, the third ground layer G3 and the signal layer S.

[0033] The thickness of the PCB circuit board is 1.6-3.2mm.

Embodiment 3

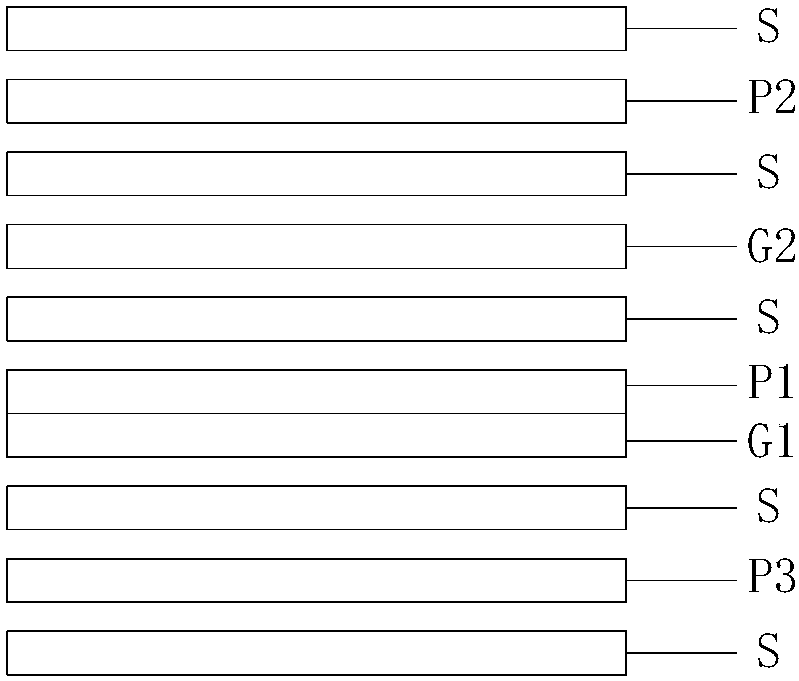

[0035] Such as image 3 As shown, the total number of layers of the PCB circuit board is 10 layers, which are the signal layer S, the second power layer P2, the signal layer S, the second ground layer G2, the signal layer S, and the first power layer from top to bottom. P1, the first ground layer G1, the signal layer S, the third power layer P3 and the signal layer S.

[0036] The thickness of the PCB circuit board is 1.6-3.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com