Method for preparing low-bitter peptide powder by enzymatic hydrolysis of wheat gluten protein

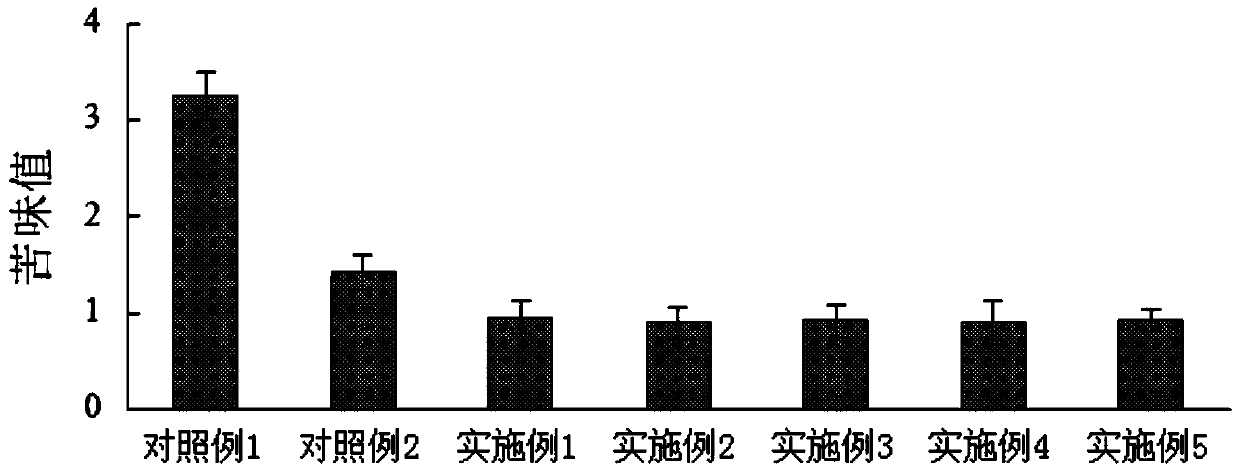

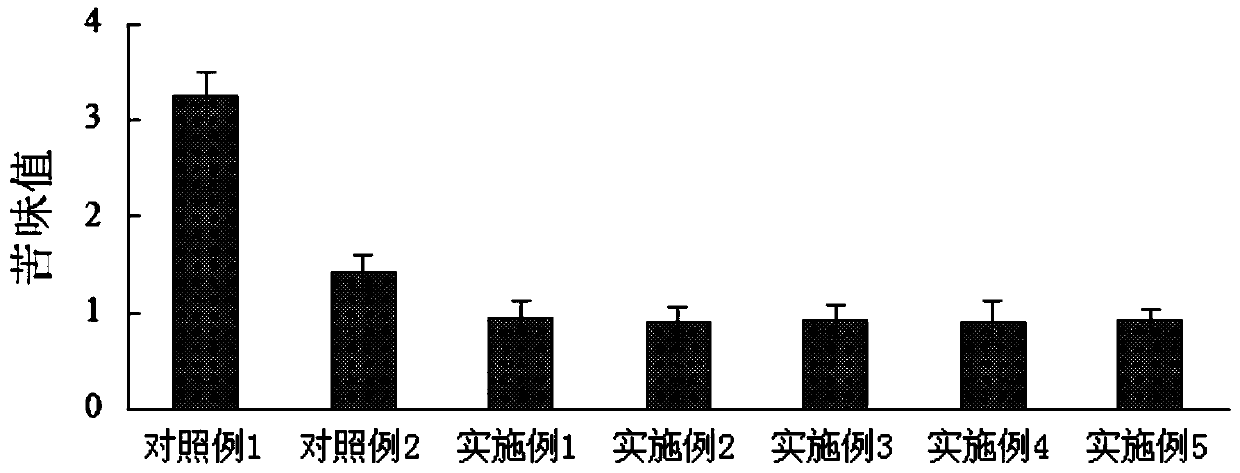

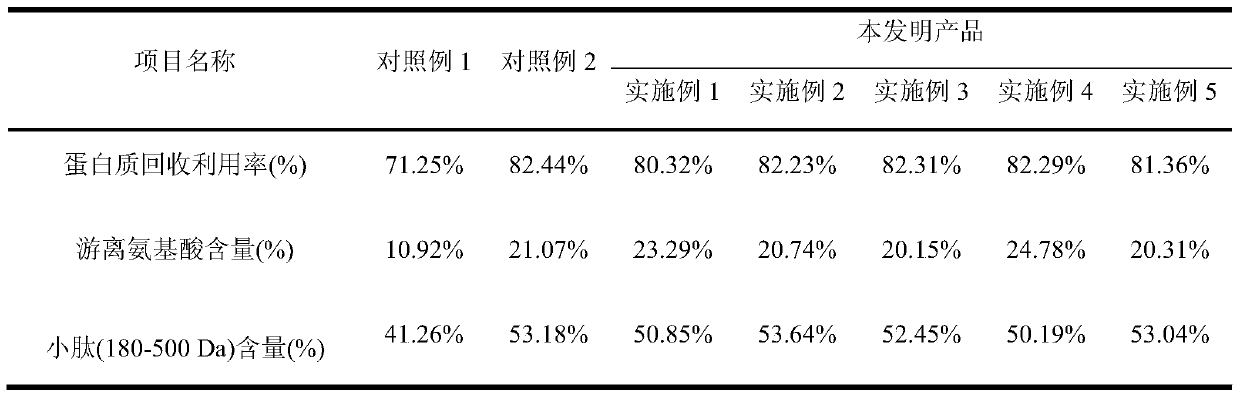

A wheat gluten protein and low bitterness technology, applied in the field of bioengineering, can solve the problems of inability to guarantee the effective content of small peptides, high bitterness value, low degree of hydrolysis, etc., achieve high amino acid retention rate, strong nutrition, and reduce the salt content of peptide powder. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Dissolve wheat gluten in water, heat up to 60°C, stir for 1 hour to solubilize, add water to make up to a solid-liquid ratio of 1:10, and when the temperature is 55°C, add 2.5% ProteAX enzyme (according to wheat gluten material mass calculation), constant temperature water bath, using NaOH solution to maintain the pH of the reaction system = 7.0, enzymatic hydrolysis for 330 minutes, and inactivating the enzyme at 95°C for 15 minutes; Then add 4% Glutaminase SD-C100S enzyme (calculated according to the mass of wheat gluten protein material), keep the temperature at 70°C, enzymolysis for 180min, after the enzymolysis reaction ends, centrifuge for 15min at a speed of 7500r / min, and collect the supernatant; The supernatant was spray-dried to obtain wheat gluten peptide powder, and then packaged to obtain wheat gluten low-bitter peptide powder rich in small peptides.

Embodiment 2

[0035] Embodiment 2: Dissolve wheat gluten in water, heat up to 55°C, stir for 1 hour to solubilize, add water to make up to a solid-liquid ratio of 1:15, and when the temperature is 50°C, add 2% ProteAX enzyme (according to wheat gluten material mass calculation), constant temperature water bath, using NaOH solution to maintain the pH of the reaction system = 7.0, enzymatic hydrolysis for 300 minutes, and inactivating the enzyme at 90°C for 15 minutes; Then add 3.5% Glutaminase SD-C100S enzyme (calculated according to the mass of wheat gluten protein material), keep the temperature at 65 ° C, enzymolysis 150min, after the end of the enzymolysis reaction, centrifuge at 7300r / min for 15min, and collect the supernatant; The supernatant was spray-dried to obtain wheat gluten peptide powder, and then packaged to obtain wheat gluten low-bitter peptide powder rich in small peptides.

Embodiment 3

[0036] Embodiment 3: Dissolve wheat gluten in water, heat up to 50°C, stir for 0.5h to solubilize, add water to make up to a solid-liquid ratio of 1:20, when the temperature is 45°C, add 1.5% ProteAX enzyme (according to wheat gluten protein Material mass calculation), constant temperature water bath, using NaOH solution to maintain the pH of the reaction system = 6.5, enzymatic hydrolysis for 270 minutes, and inactivating the enzyme at 90°C for 10 minutes; when the temperature is cooled to 65°C, use HCl or NaOH to adjust the pH of the enzymolysis solution after inactivating the enzyme = 6.0 , followed by adding 3% Glutaminase SD-C100S enzyme (calculated according to the mass of wheat gluten material), keeping the temperature at 60°C, enzymolysis for 120min, after the enzymolysis reaction was completed, centrifuged at 7000r / min for 10min, and collected the supernatant; The collected supernatant is spray-dried to obtain wheat gluten peptide powder, and then packaged to obtain wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com