Electrical connector and assembly method thereof

A technology of electrical connectors and assembly methods, which is applied in the direction of connection, structural connection of printed circuits, printed circuits connected with non-printed electrical components, etc., which can solve tin cracks and affect the electrical connection between electrical connectors and circuit boards, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate a better understanding of the content of the present invention, the present invention will now be further described with reference to the accompanying drawings and specific embodiments.

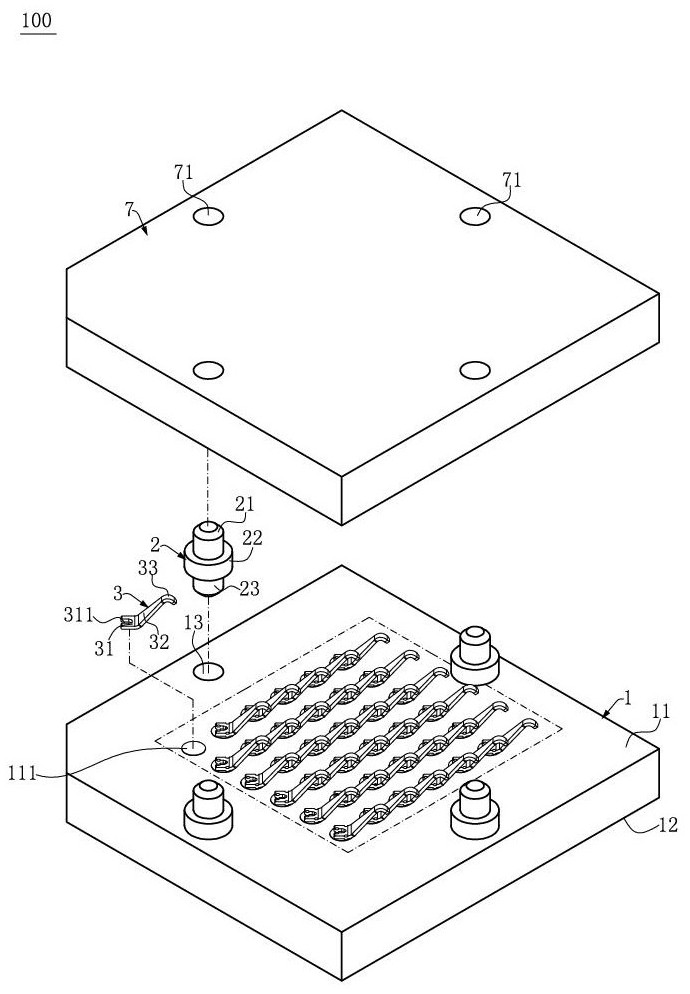

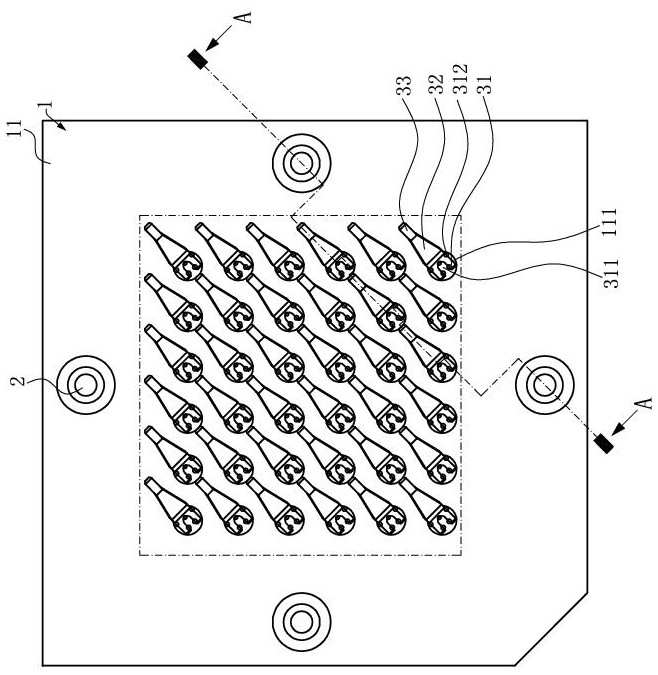

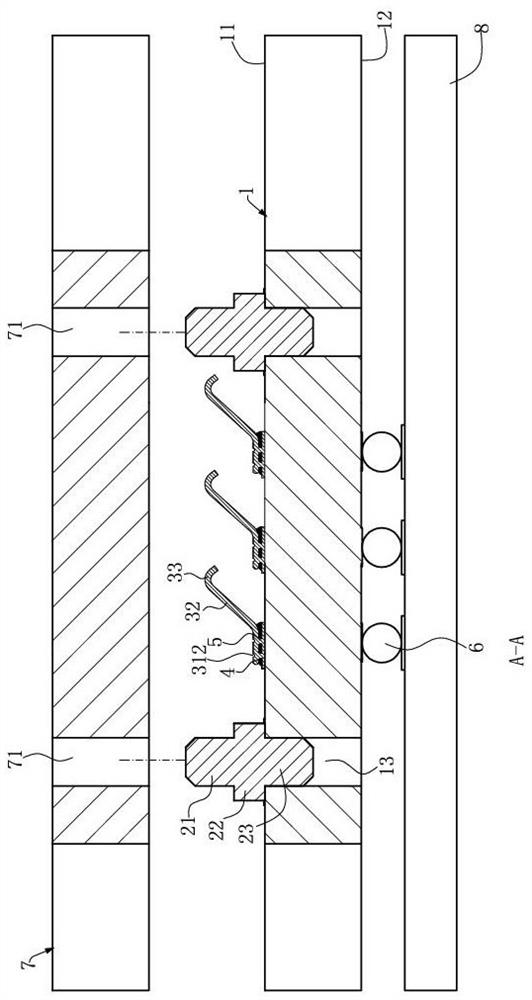

[0027] like figure 1 , image 3 As shown, as the best embodiment, the electrical connector 100 of the present invention is used to electrically connect a chip module 7 to a main board 8, and the electrical connector 100 includes a circuit board 1, a plurality of terminals 3 soldered to The circuit board 1 and a plurality of fixing members 2 are fixed on the circuit board 1 .

[0028] like figure 1 , image 3 As shown, the circuit board 1 is provided with an opposite upper surface 11 and a lower surface 12 and a plurality of first through holes 13 passing through the upper surface 11 and the lower surface 12, and the upper surface 11 is provided with a plurality of first through holes 13. The conductive pad 111 is provided with a plurality of solders 6 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com