Air conditioner for vehicle capable of preventing inverter overheating

An air conditioner and overheating technology, which is applied to irreversible cycle compressors, vehicle components, air handling equipment, etc., can solve the problems of motor drive unit temperature rise, pressure rise, and refrigerant flow path damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

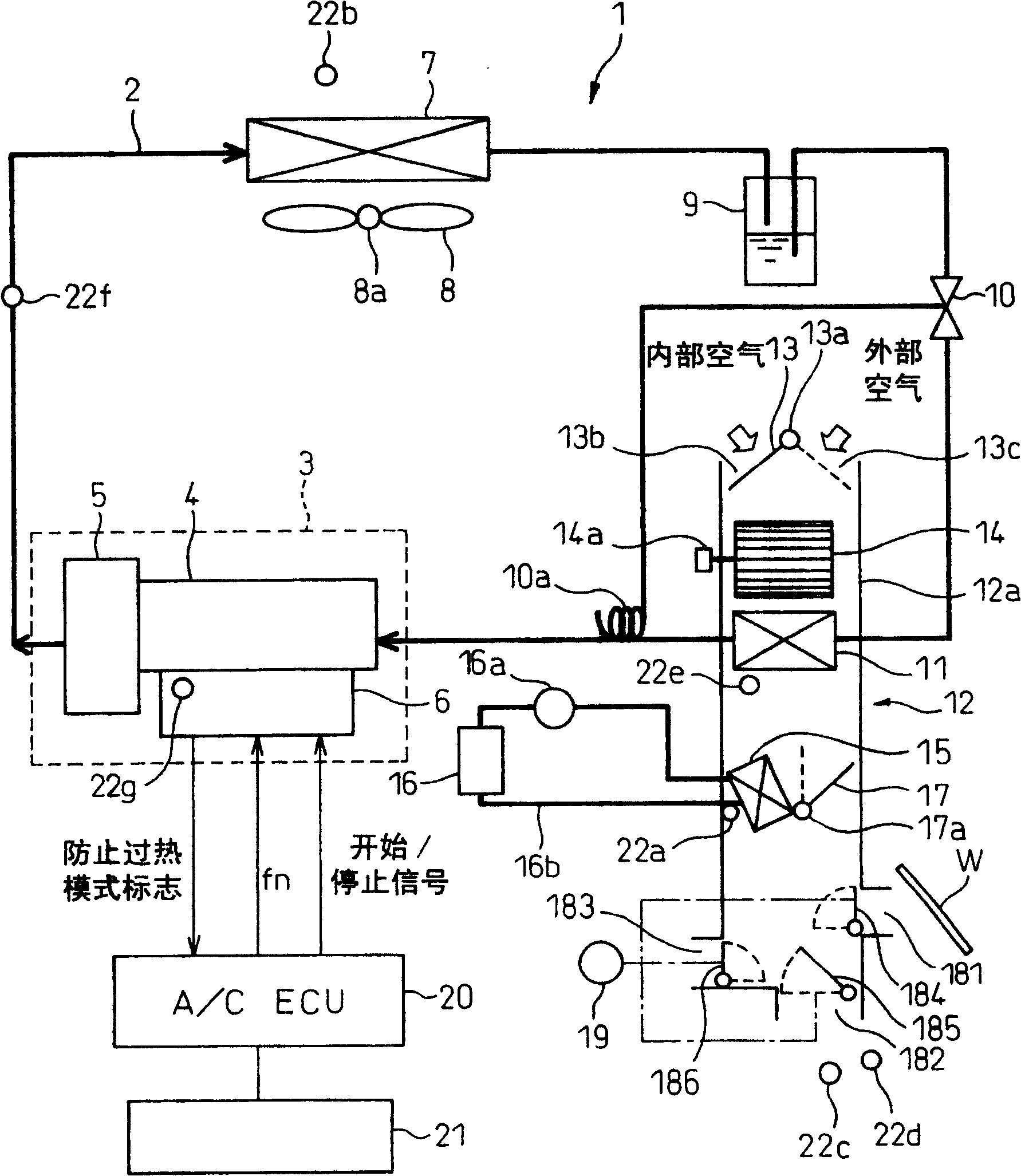

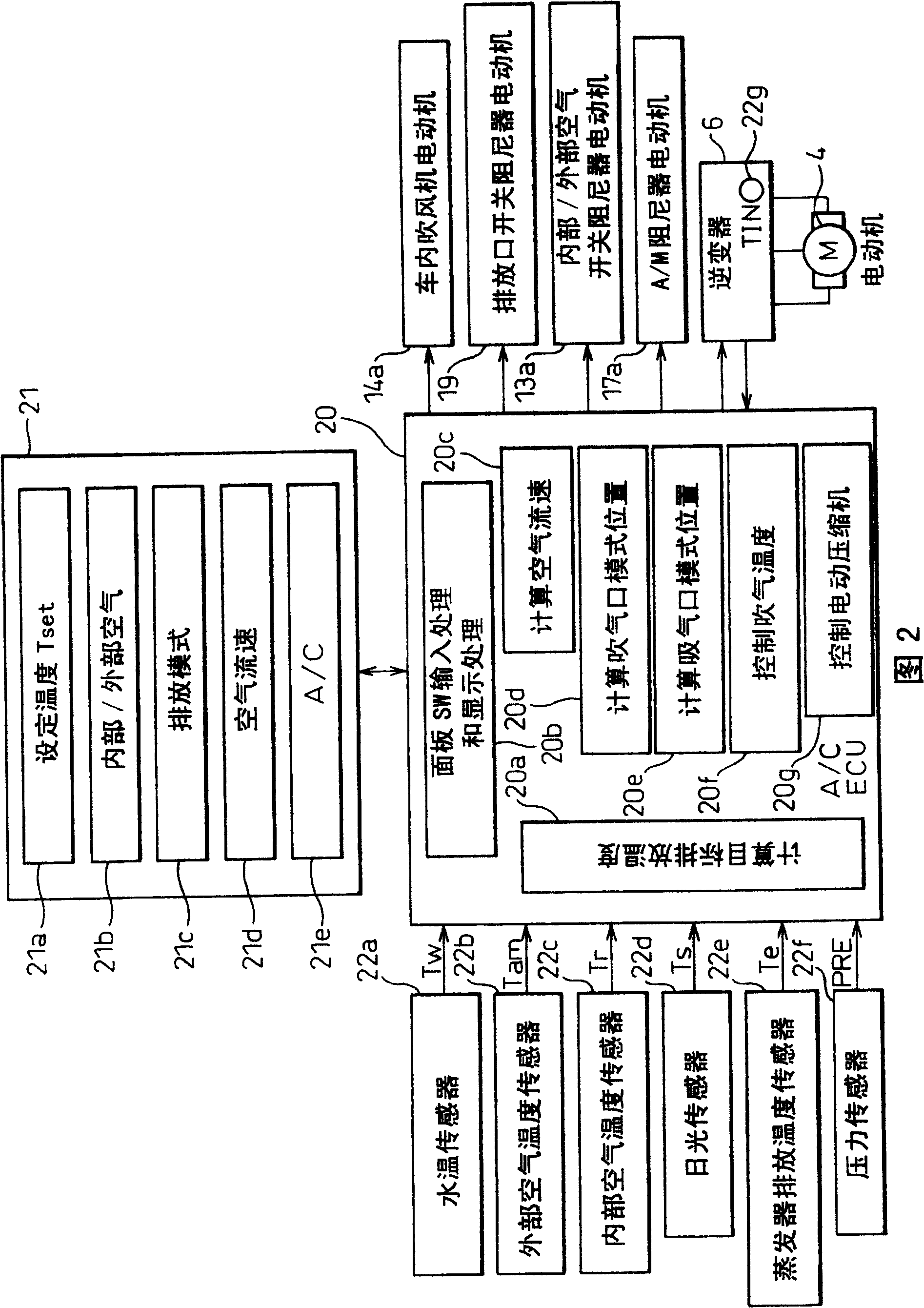

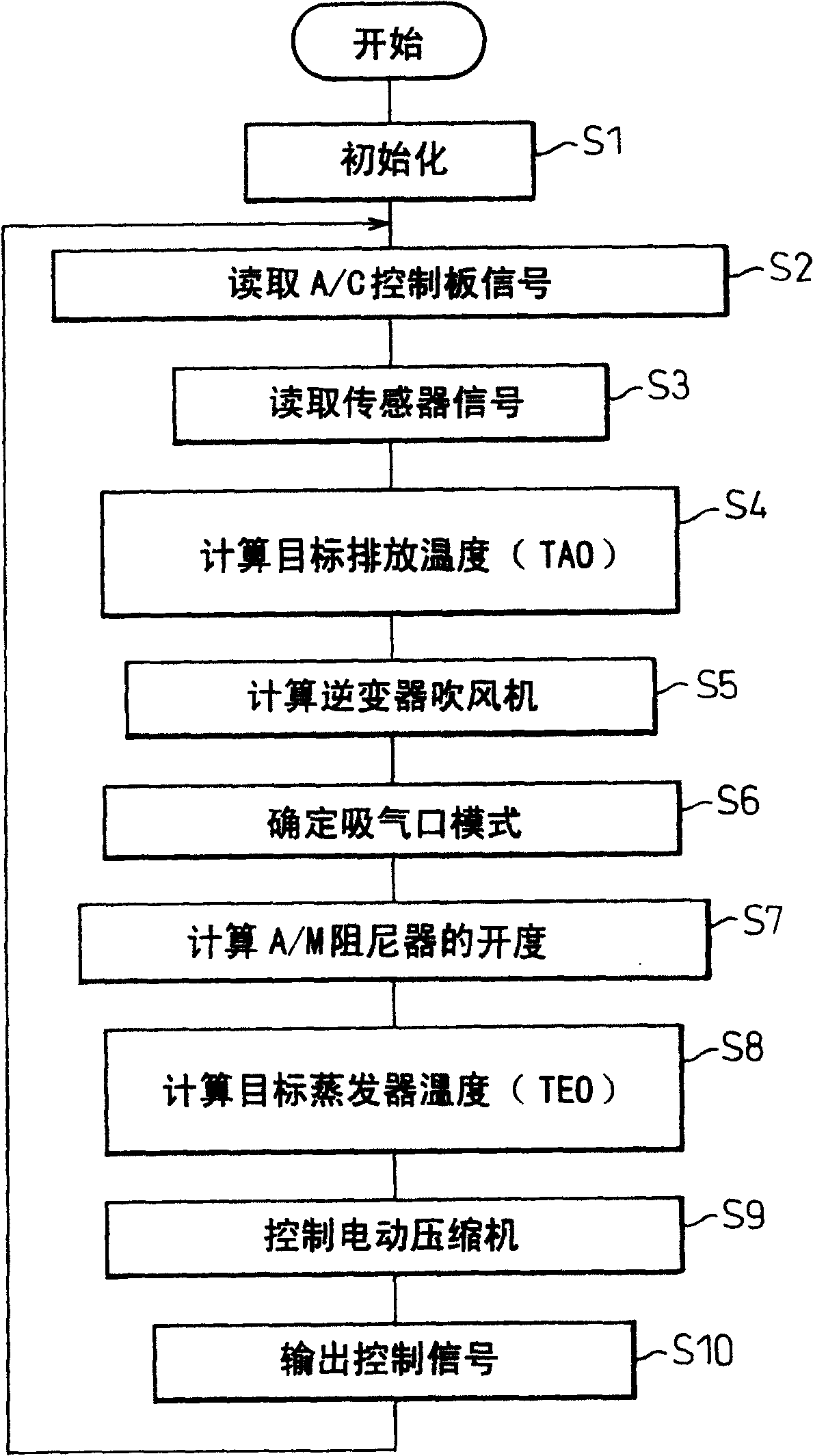

[0037] figure 1 It is a block diagram showing the general structure of the vehicle air conditioner in the present invention. The refrigeration cycle 2 of the air conditioner for the vehicle 1 includes an electric compressor 3 that sucks in, compresses, and discharges refrigerant. The electric compressor 3 includes an electric motor 4 and a compression mechanism 5 driven by the electric motor 4, both of which are integrally formed in one unit. Specifically, the electric motor 4 is a three-phase AC motor, and the compression mechanism 5 is, for example, a well-known screw-type compression mechanism. Thus, the compression mechanism 5 can continuously change the discharge amount in the range of 0% to 100% according to the rotation speed of the electric motor 4 .

[0038] By variably controlling the frequency of the three-phase AC power supplied to the motor 4 by using the inverter 6 as a motor drive unit, the rotation speed of the motor 4 can be controlled at a rotation speed pr...

no. 2 example

[0111] In the above-mentioned first embodiment, the air conditioner control unit 20 judges whether the inverter 6 is working in the overheating prevention mode by detecting the overheating prevention mode flag output by the inverter 6, but in the second embodiment, the inverter 6 The temperature TIN detected by the inverter temperature sensor 22g is output to the air conditioner control unit 20, and the air conditioner control unit 20 judges the operating state of the inverter 6 based on the inverter temperature TIN from the inverter 6.

[0112] Figure 9 Showing the operation judgment procedure of the inverter 6 in the air conditioner control unit 20 of the second embodiment, FIG. 10 shows the control procedure of the inverter 6 in the second embodiment. As in the operation judging program in the first embodiment ( Figure 7 ) is the same as in the control program (Fig. 8), the same process is attached with the same sign, which will not be described here. In addition, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com