Heating device for components

A technology for equipment and components, applied in the field of equipment for heating components, can solve the problems of high cost and complicated pit construction technology, and achieve the effects of speeding up assembly, shortening time, and saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

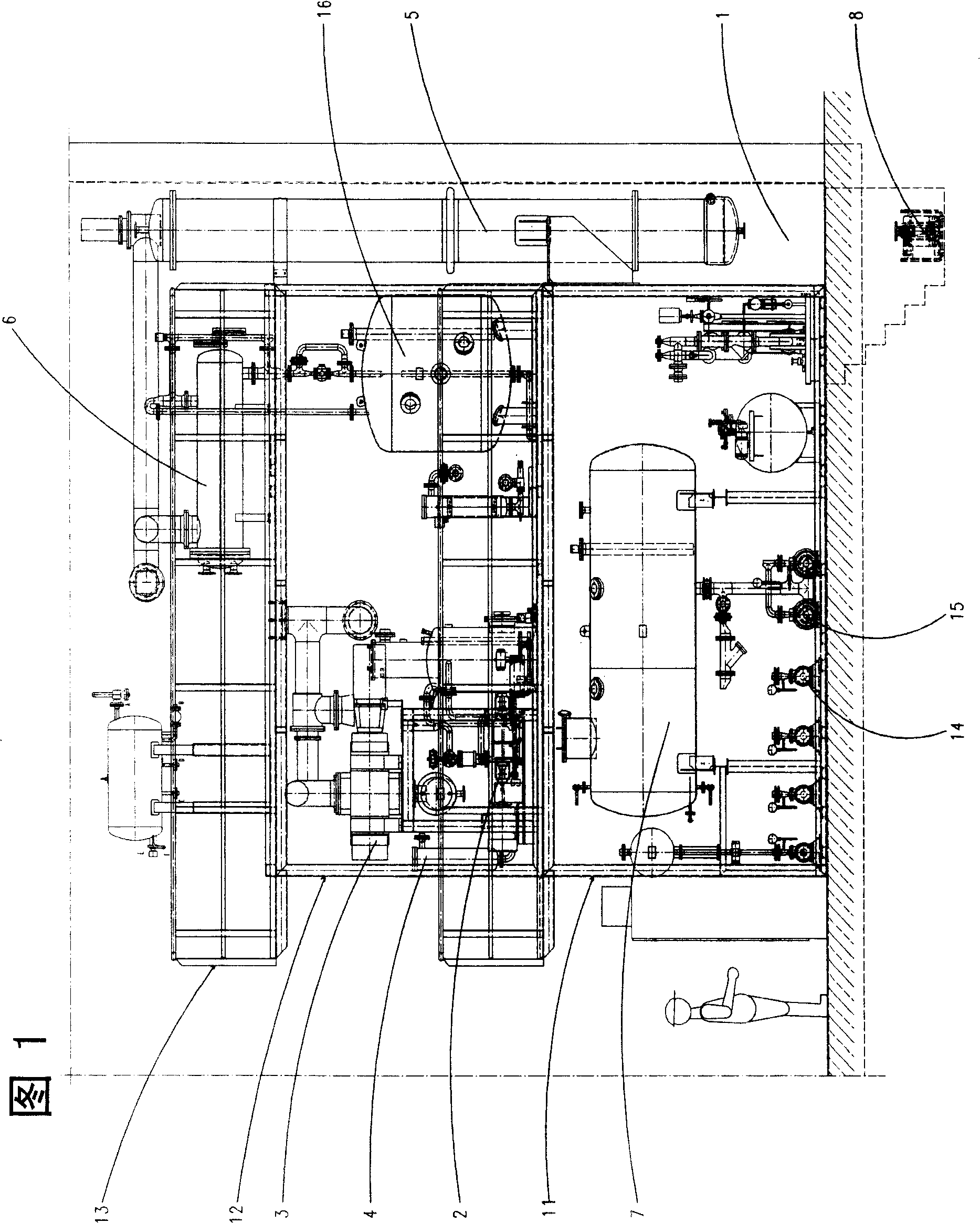

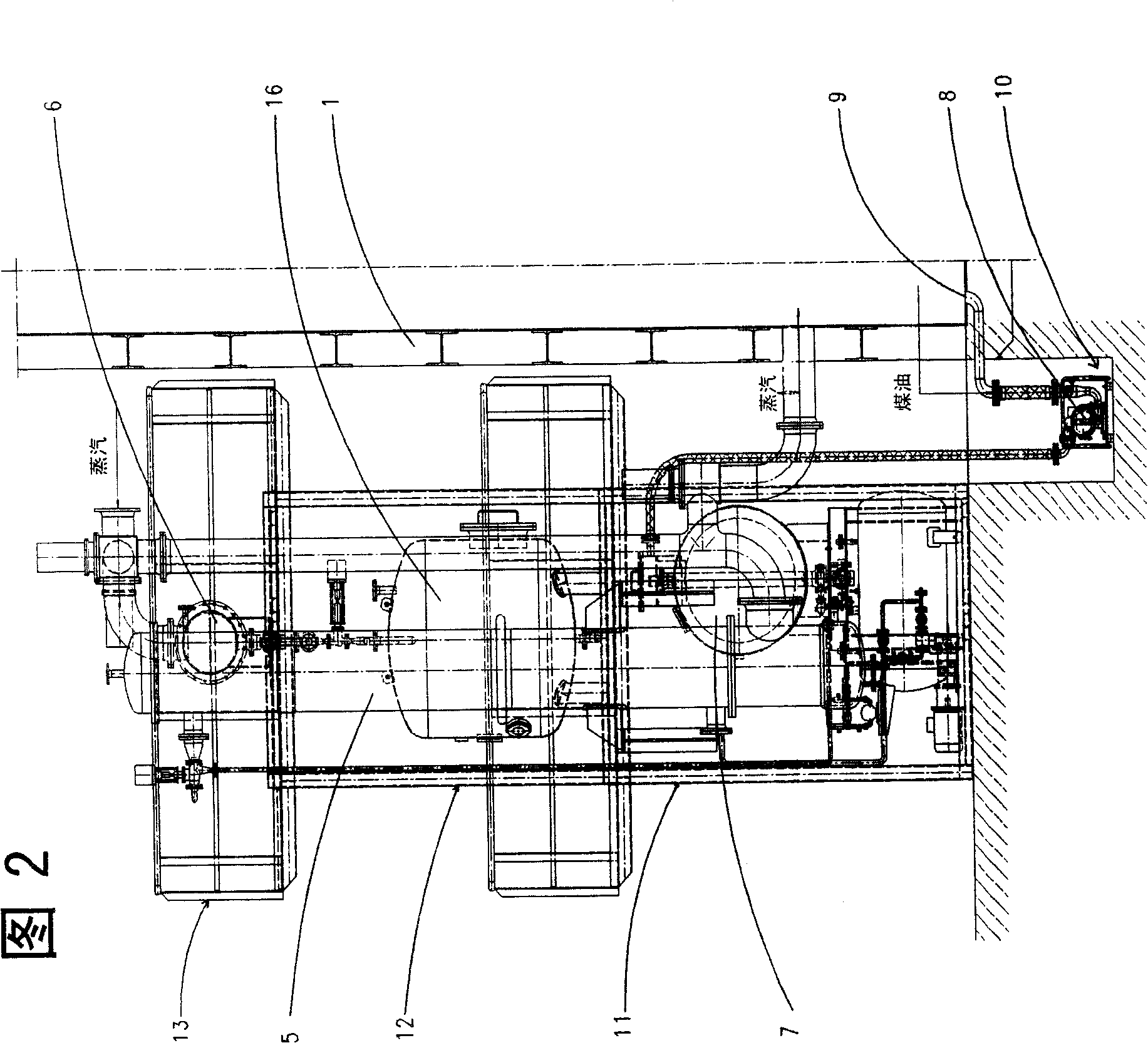

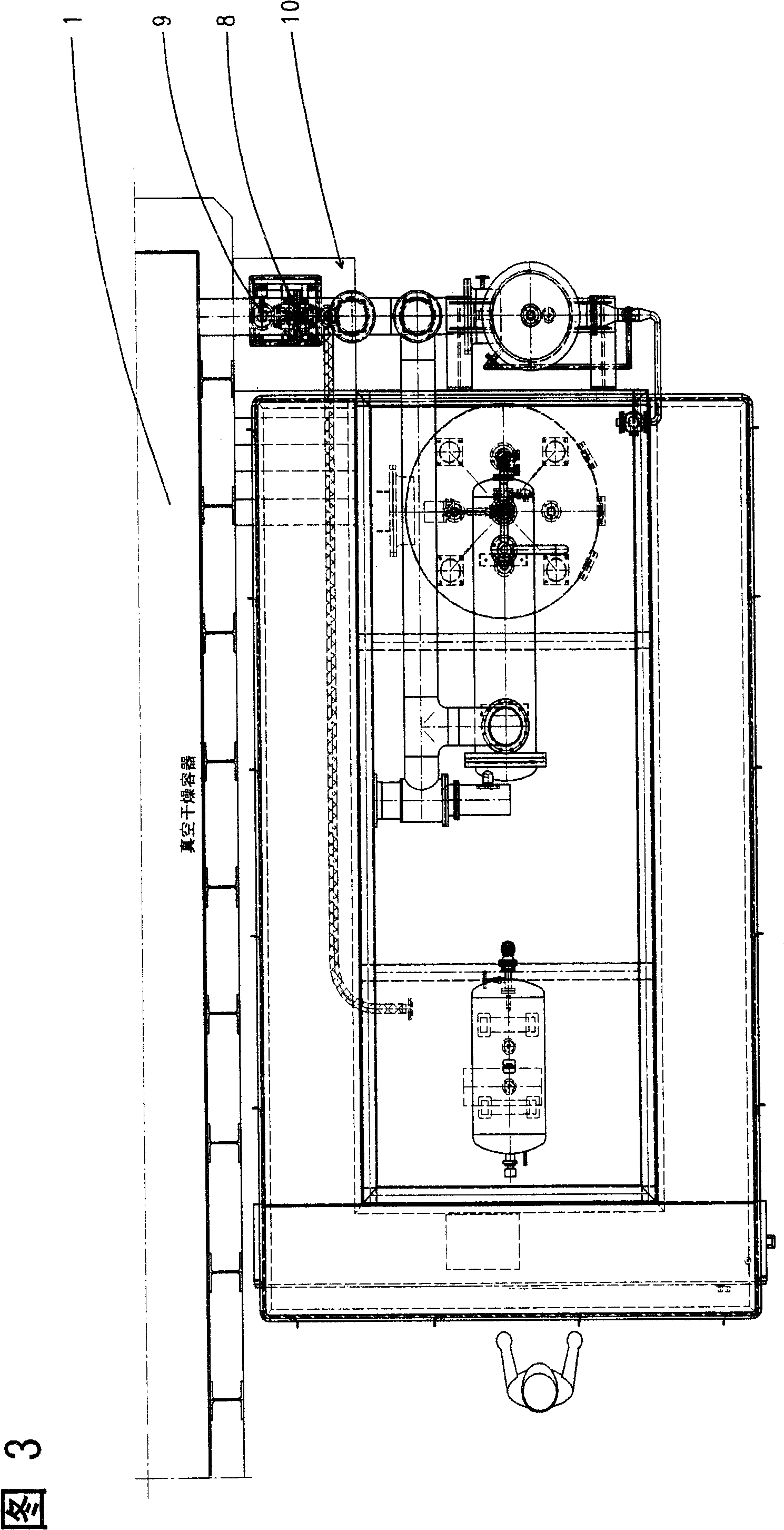

[0029] These figures show a so-called vapor phase plant, which is used, for example, for heating and drying components with hygroscopic electrical insulation parts based on cellulose and / or plastic, especially for transformers, capacitors and the like.

[0030] The basic structure of such a device and its mode of operation are described, for example, in DE 196 37 313 C2.

[0031] According to this document, the device has an evacuable vacuum chamber 1 in which transformers to be dried are inserted.

[0032] An evaporator for evaporating the heat transfer liquid is connected to the vacuum chamber 1 via a shut-off valve (not shown separately). A bypass line, which can also be closed via a valve, leads to a condenser 6 . The possibility of draining the second liquid with a higher boiling point, in particular transformer oil, is to lead via a (not shown) valve to the delivery pump 14 or via a (not shown) valve to a collecting container 7 , Through this collecting vessel, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com