Vein-like tubular pile

A pipe pile and tendon-shaped technology, which is applied in the field of concrete pipe pile manufacturing, can solve the problems that the raised bamboo joints cannot form a strong support, the density of the upper soil cannot be increased, and the bearing pressure of the pipe pile cannot be increased. To achieve the effect of expanding the effective support area, reducing the cost of pile pressing, and reducing the difficulty of pile pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

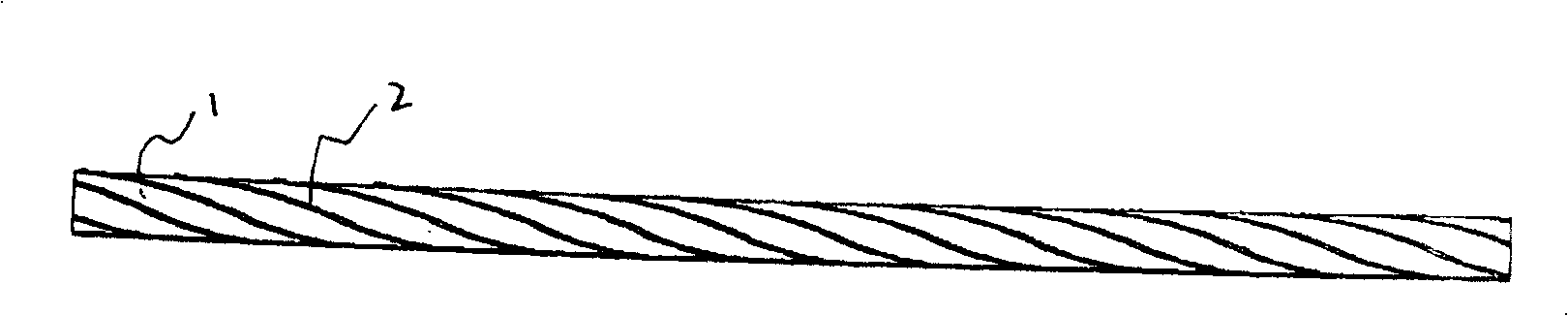

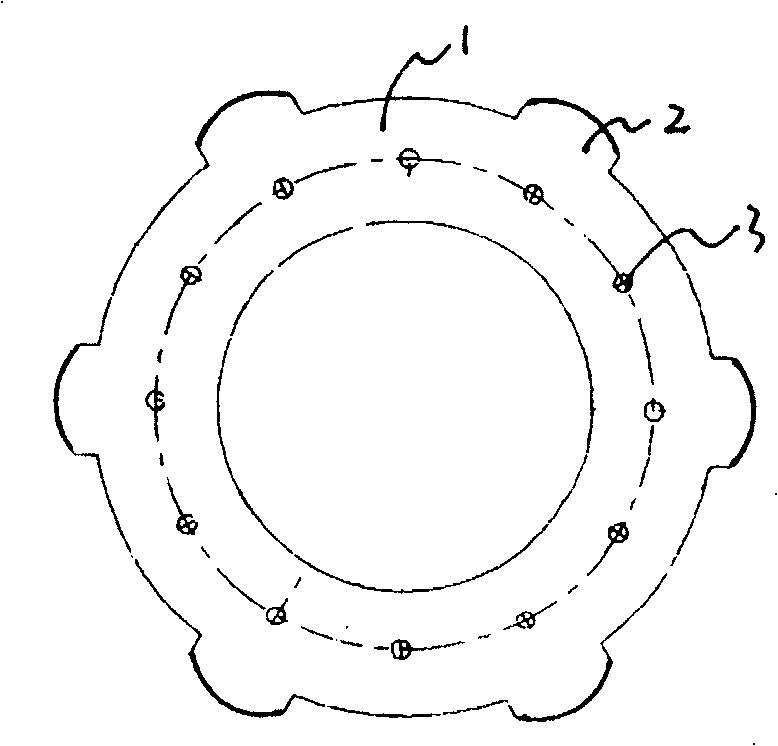

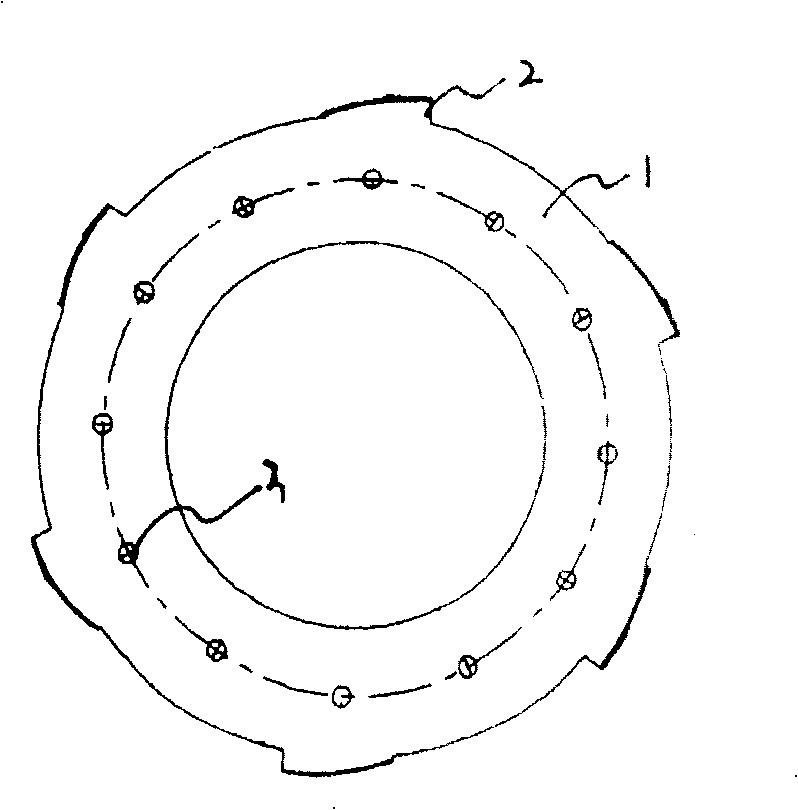

[0021] Embodiment 1: with reference to attached figure 1 with 2 . Spiral tendon-shaped pipe pile, which includes a pile body 1, a reinforcement rib 3 is arranged in the pile body 1, and there are 1 or 2 or more than 2 spiral raised ribs 2 on the outer wall of the pile body 1 and are connected with the The pipe pile 1 has an overall structure, and the spiral raised ribs 2 are arc-shaped, and any spiral raised ribs on the pile body 1 do not overlap each other from beginning to end. The pile body 1 is in the shape of a cylinder, a square column, a rhombic column, a rectangle, a polygon, or a convex-concave tongue-and-groove shape. The production of the spiral pipe piles is first made into a model by using the existing technology, and the production technology of the concrete pipe piles is the existing technology, which will not be described here.

Embodiment 2

[0022] Embodiment 2: with reference to attached figure 1 with 3 . On the basis of Embodiment 1, the spiral protruding rib 2 is arc-shaped.

Embodiment 3

[0023] Embodiment 3: with reference to attached figure 1 with 4 . On the basis of Embodiment 1, the helical protruding ribs 2 are in a convex-concave arc shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com