Hydraulic tensioning device for a traction mechanism drive

A technology for tensioning devices and tools, which is applied in the direction of transmission devices, valve devices, engine components, etc., and can solve problems such as installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

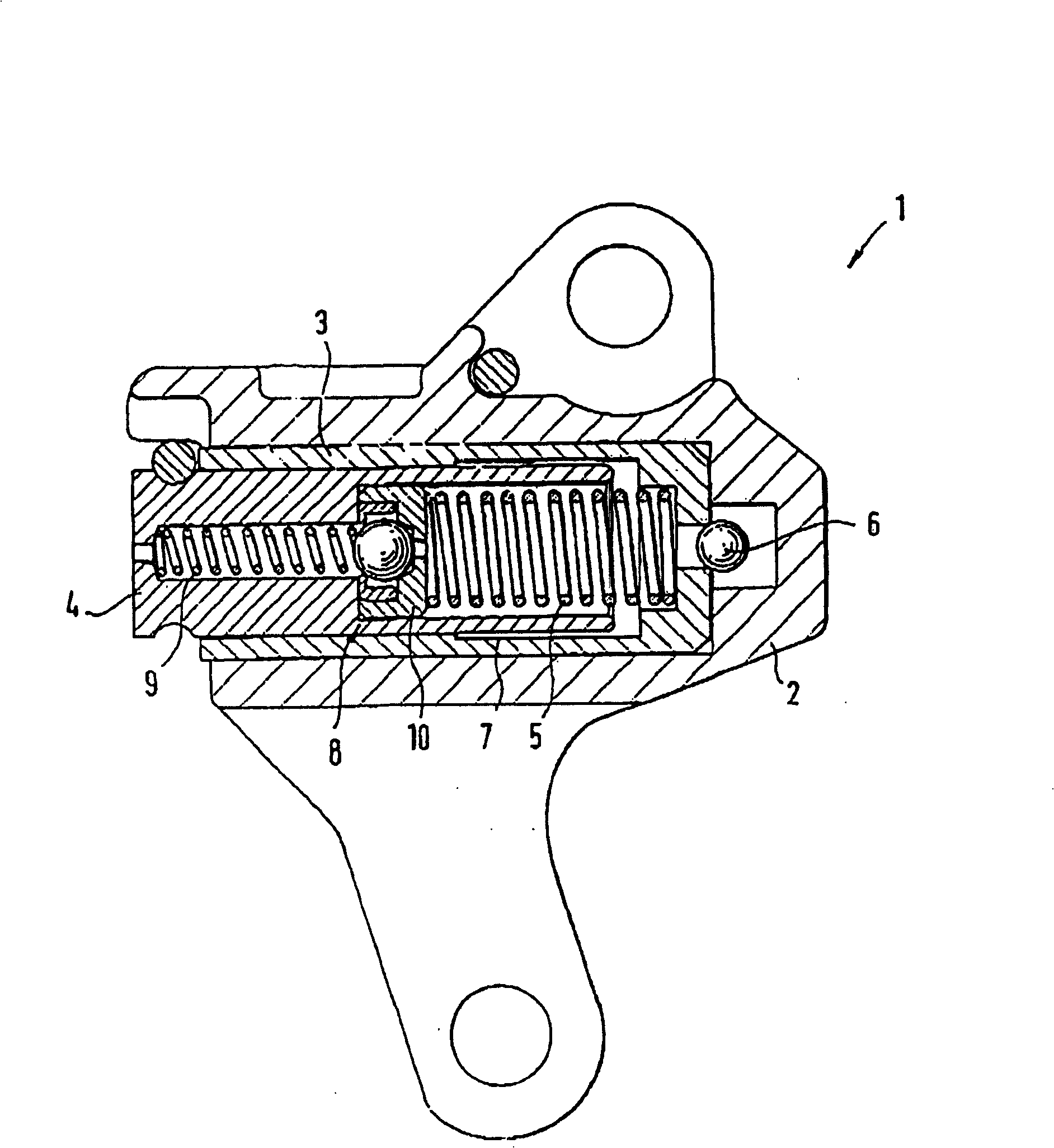

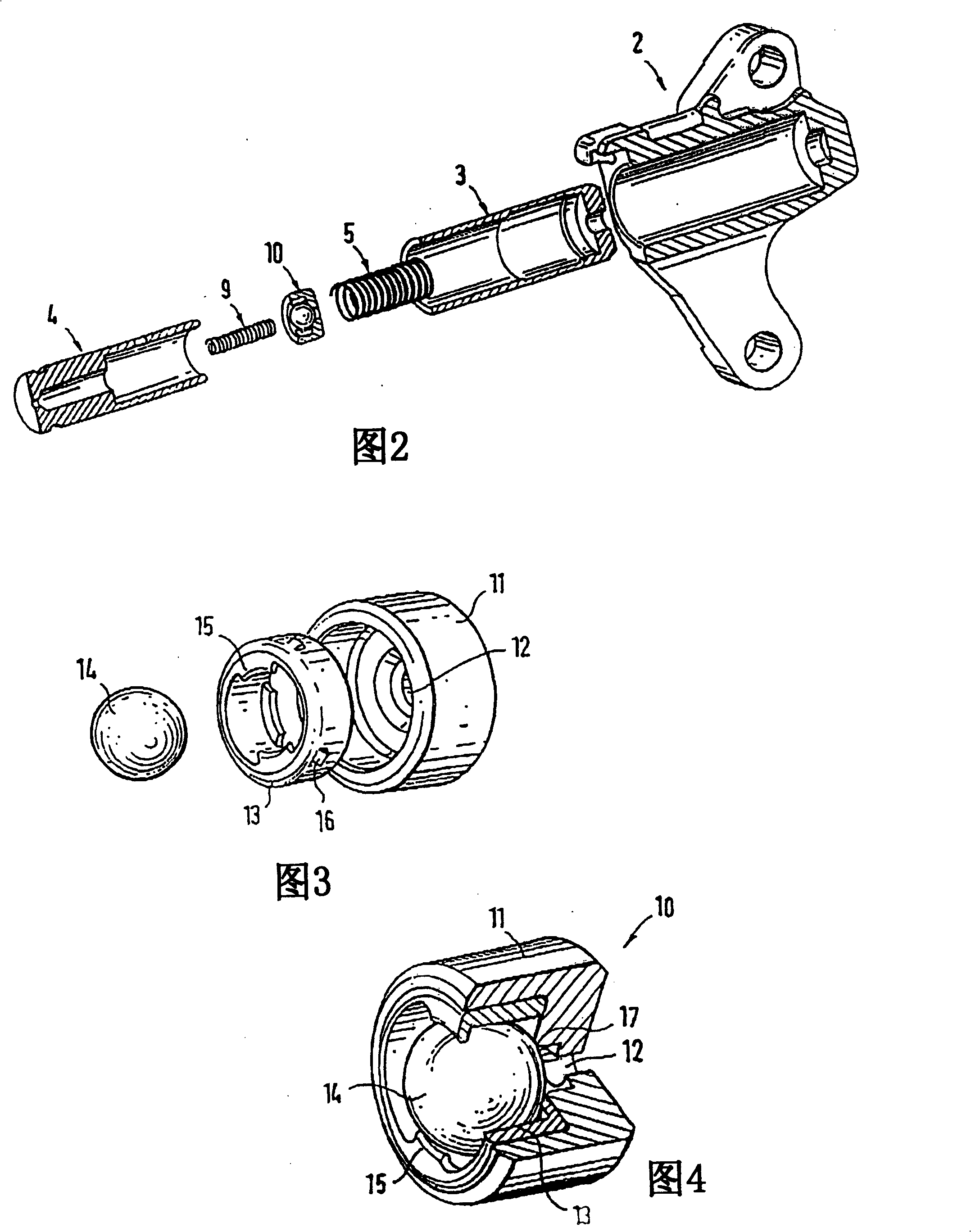

[0020] figure 1 An assembly drawing showing a partial section of the tensioner. The tensioning device shown is a chain tensioner for tensioning the drive chain of an internal combustion engine.

[0021] The hydraulic tensioning device 1 basically consists of a housing 2 into which a housing 3 of the tensioner hydraulics is inserted. A tensioner piston 4 is axially movably accommodated inside the tensioner hydraulic part housing 3 . During work, the front side of the tensioner piston 4 is closely attached to the transmission chain.

[0022] The tensioner hydraulic housing 3 and the tensioner piston 4 , which are simultaneously used as cylinders for the tensioner piston 4 , form a pressure chamber, which is filled with a hydraulic fluid, usually engine oil. A tensioner main spring 5 is arranged in the pressure chamber, which is designed as a pressure spring and presses the tensioner piston 4 outwards against the chain until a balance between the spring force and the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com