Intelligent tunnel section flattening device

A technology for sections and tunnels, applied in the field of intelligent tunnel section leveling devices, can solve the problems of construction problems without detailed data support, affecting construction procedures, and prolonging construction periods, achieving intelligent tunnel section operations, ensuring flatness and quality requirements, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

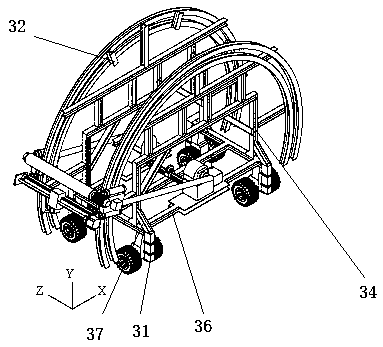

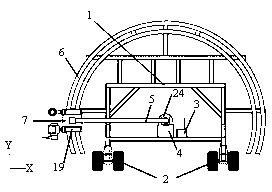

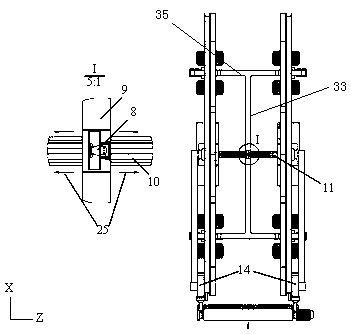

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings of the present invention.

[0036] The technical module that the inventive point of the present invention relates to is as follows:

[0037] 1. The existing tunnel leveling devices are all simple mobile spray guns, etc. The present invention uses the linkage of rollers, spray guns, guide rails, hydraulic cylinders, motors, and rotating rods, which has wider coverage and wider uses.

[0038]2. The present invention uses the design of I-beam, upper and lower guide rails, multiple beams, and vertical beams. There are a large number of hollow structures in the bracket, which greatly saves the cost and ensures the strength and rigidity at the same time. At the same time, structural auxiliary connections such as clamping blocks are used to ensure the overall stability.

[0039] 3. The traditional mobile work vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com