Liquid crystal display unit anjd producing method thereof

A technology of liquid crystal display unit and liquid crystal display device, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of narrowing the scope of the display area, violating the development trend of liquid crystal displays, and increasing the space of liquid crystal panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

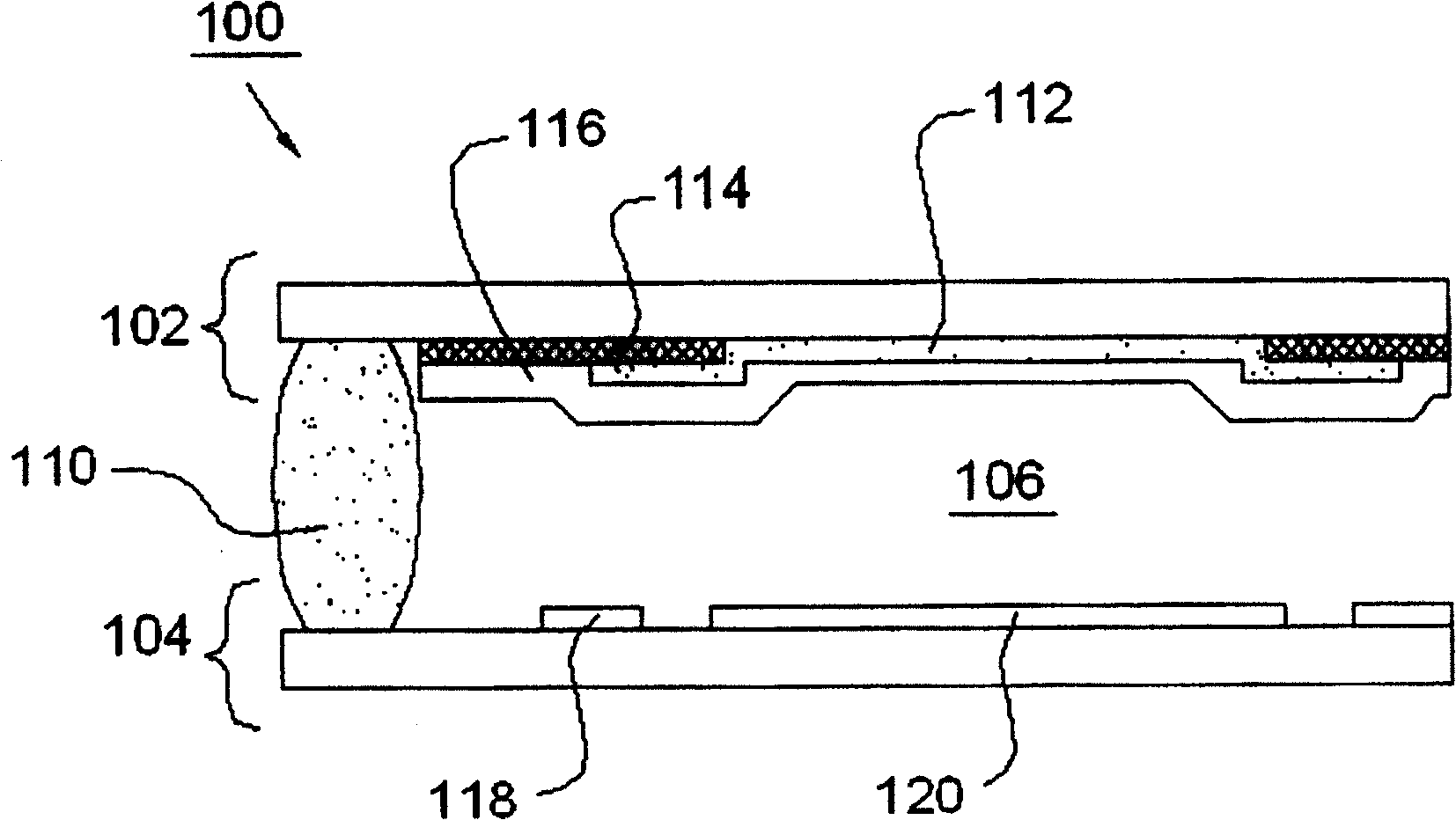

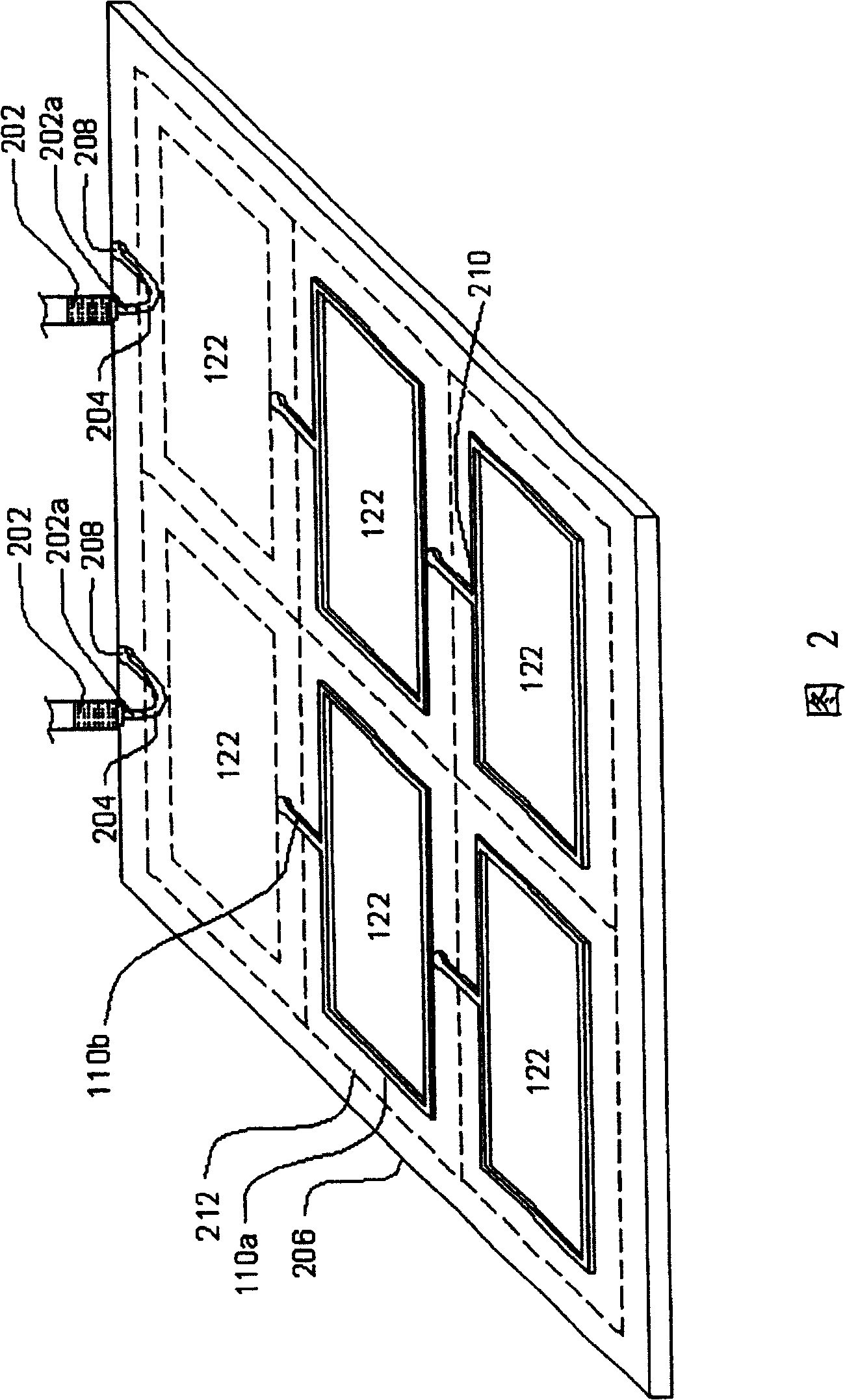

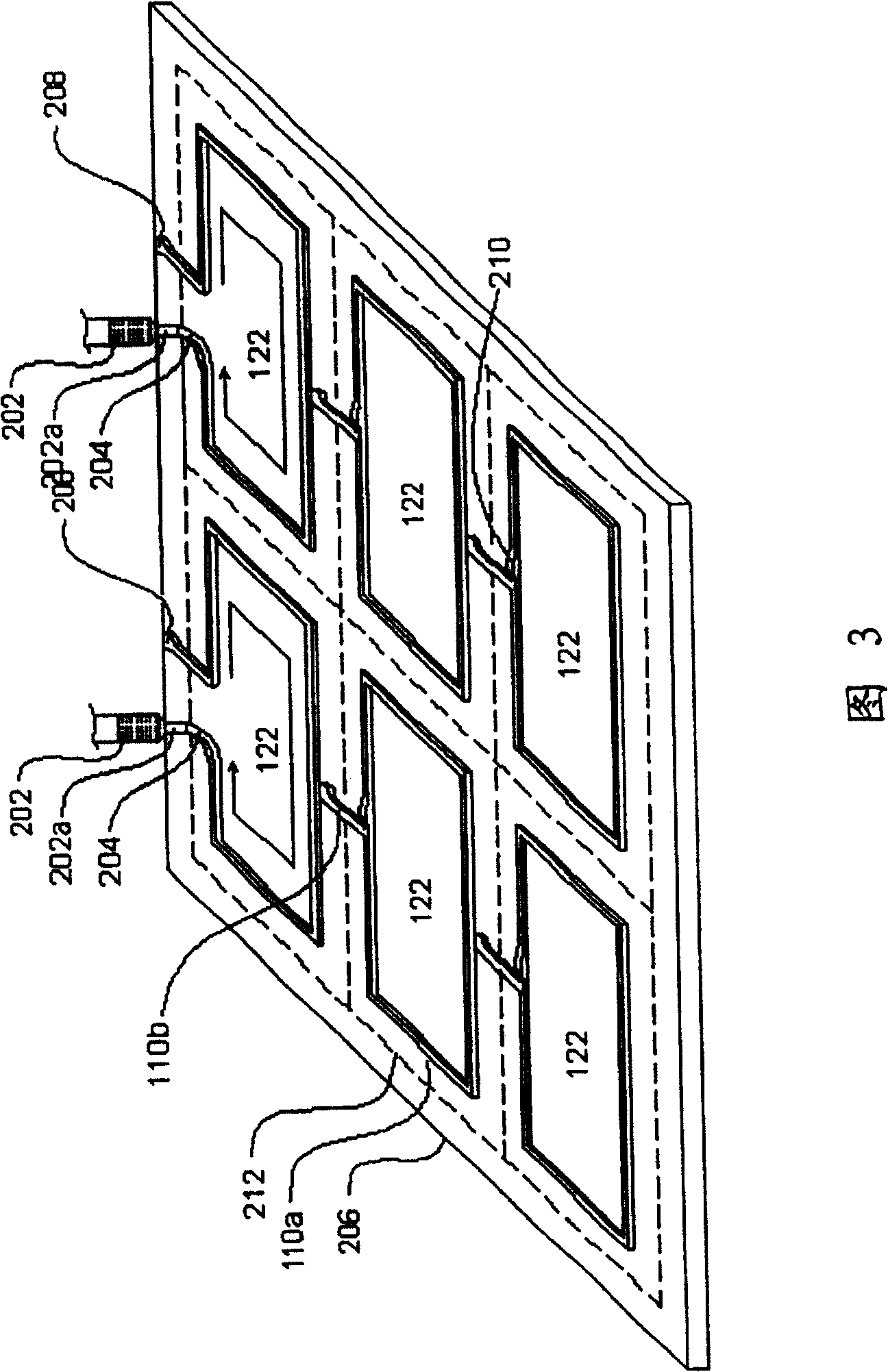

[0016] figure 1 and Figure 4 A liquid crystal display unit 100 according to an embodiment of the present invention is shown. refer to figure 1 , the liquid crystal display unit 100 comprises a substrate 102, a substrate 104, a liquid crystal layer 106 sandwiched between the substrates 102 and 104, and a sealing member 110 (see Figure 4 ), the sealing member 110 seals the liquid crystal layer 106. The liquid crystal layer of the liquid crystal display unit 100 is formed by a drop injection method.

[0017] refer to figure 1 , the substrate 102 is a color filter substrate, which is provided with: a plurality of color filter regions 112 (in figure 1 One color filter region 112 is represented in the figure), a light shielding matrix 114 between adjacent color filter regions 112 , and a transparent electrode 116 substantially covering the entire surface of the substrate 102 . The substrate 104 is a thin film transistor substrate, on which a plurality of parallel data lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com