Coupling type clutch

A clutch and coupling technology, applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc., can solve the problems of single function, complex structure, high processing precision requirements and high cost, and achieve wide application, simple basic structure, The effect of combining high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

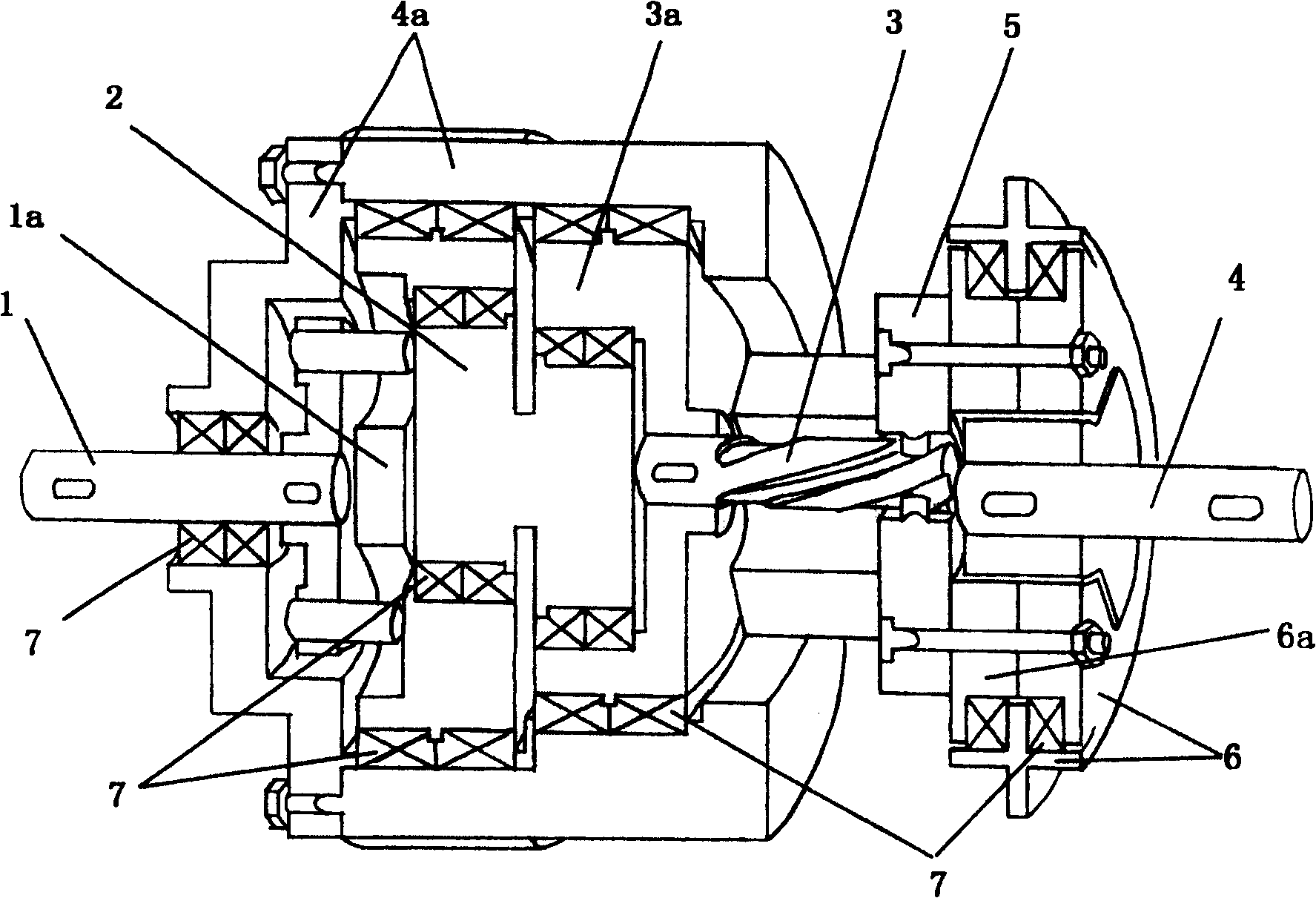

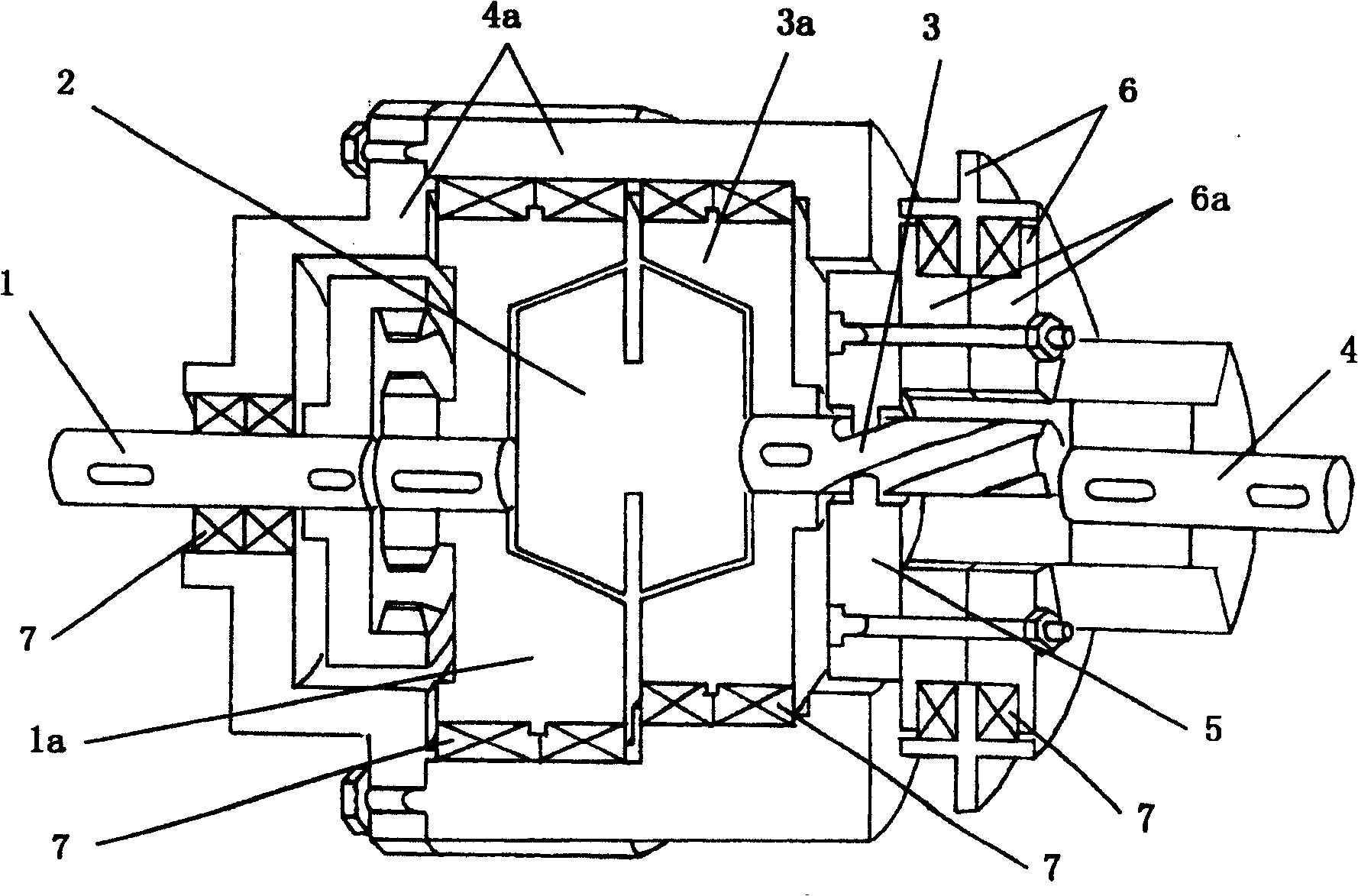

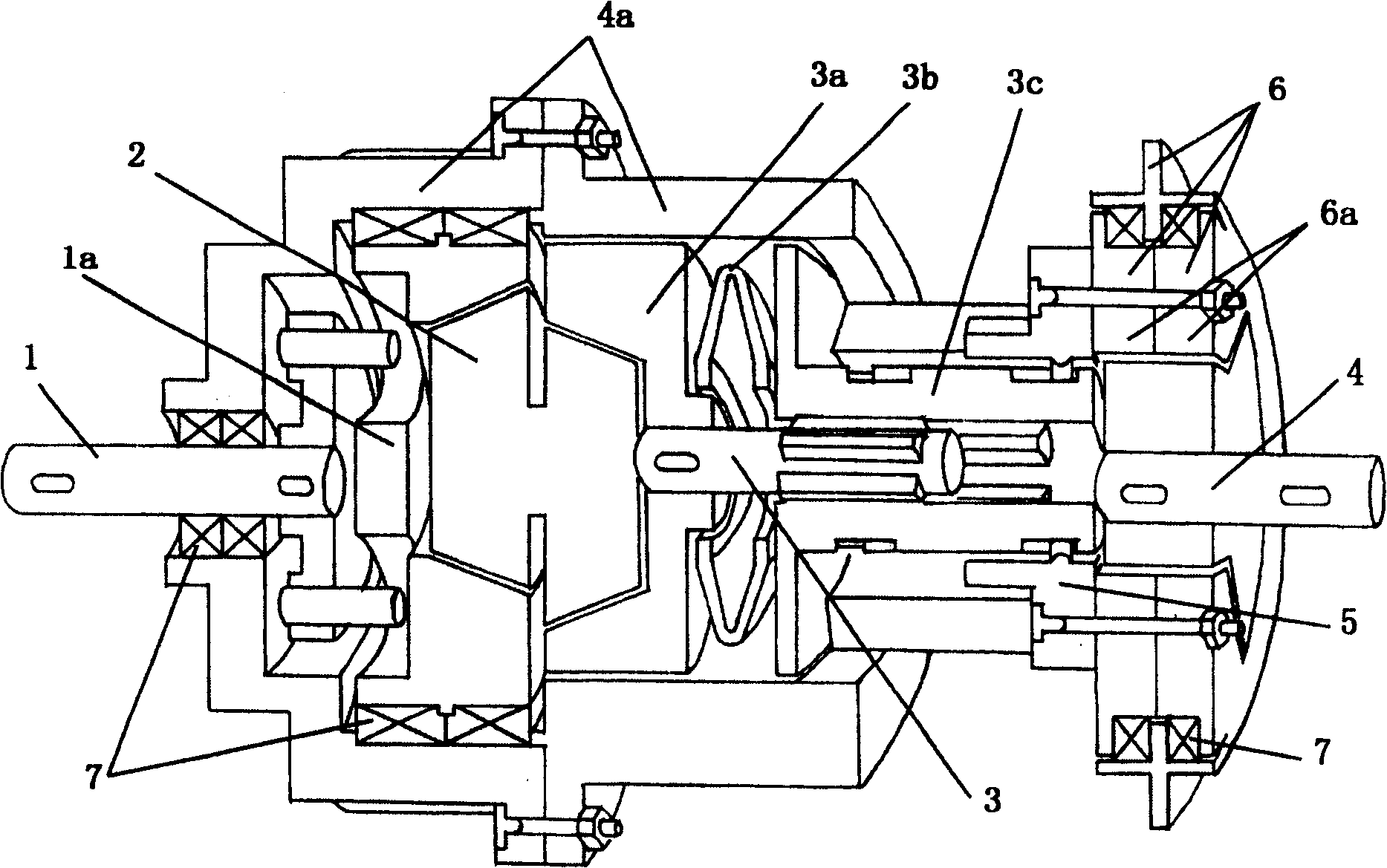

[0036] see Figure 1~5 , the present invention is provided with first transmission shaft 1, wheel disc 1a, eccentric wheel 2, self-aligning shaft 3, self-aligning wheel disc 3a, spring 3b, spiral bushing 3c, second transmission shaft 4, transmission case 4a, pin Gear 5, clutch control disc 6 (the inner sleeve 6a of clutch control disc is provided therein), bearing 7 and so on.

[0037] The first transmission shaft 1 and the wheel disc 1a are gear meshingly connected, and may also be connected by fixed connection, constant speed or differential mechanism (such as being connected by a gear train or a constant speed output mechanism), and the first transmission shaft 1 and the wheel disc 1a pass through The bearing 7 is connected with the transmission housing 4a and the left end of the eccentric wheel 2 respectively. The self-aligning shaft 3 is fixedly connected with the self-aligning wheel 3a, and the self-aligning wheel 3a is respectively connected to the right end of the ecc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com