Online method for testing burn through index

A detection method and index technology, applied in the field of endpoints, can solve problems such as high labor intensity, large impact of tail dust, non-compliance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

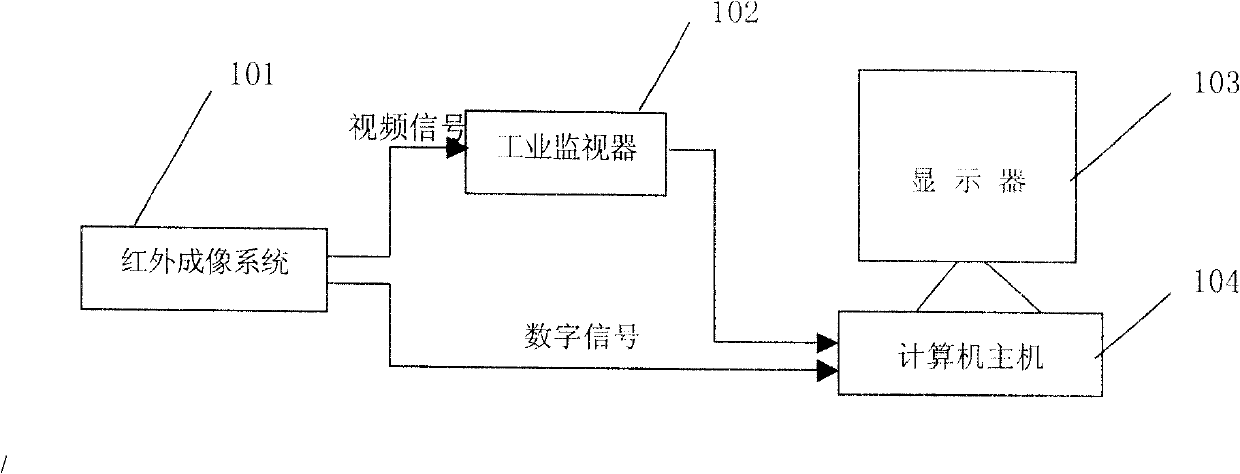

[0040] based on the following figure 1 , illustrating the best mode of implementation of the present invention.

[0041] Such as figure 1 As shown, it is a schematic structural diagram of using the method of the present invention to perform on-line detection of the burn-through index; it includes: an infrared imaging system 101, an industrial monitor 102, a computer host 103 and a display 104; the infrared imaging system 101 provides two signals at the same time, one A video signal is provided to transmit the actual image of the sinter bed section at the sinter tail to the industrial monitor 102 for on-site operators to directly observe; the other channel provides a digital signal to transmit the digital image of the sinter bed section at the sinter tail to the computer host 103.

[0042] The burn-through index online detection method provided by the present invention comprises the following steps:

[0043] 1. The infrared imaging system 101 scans the image of the sinter bed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com