Roll napkin manufacturing device

A technology for manufacturing devices and roll towels, which is applied in the field of roll towel manufacturing devices, and can solve problems such as inability to provide roll towels, excessive water supply, and roll towels that cannot be formed independently, and achieve the effect of preventing excessive or insufficient water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

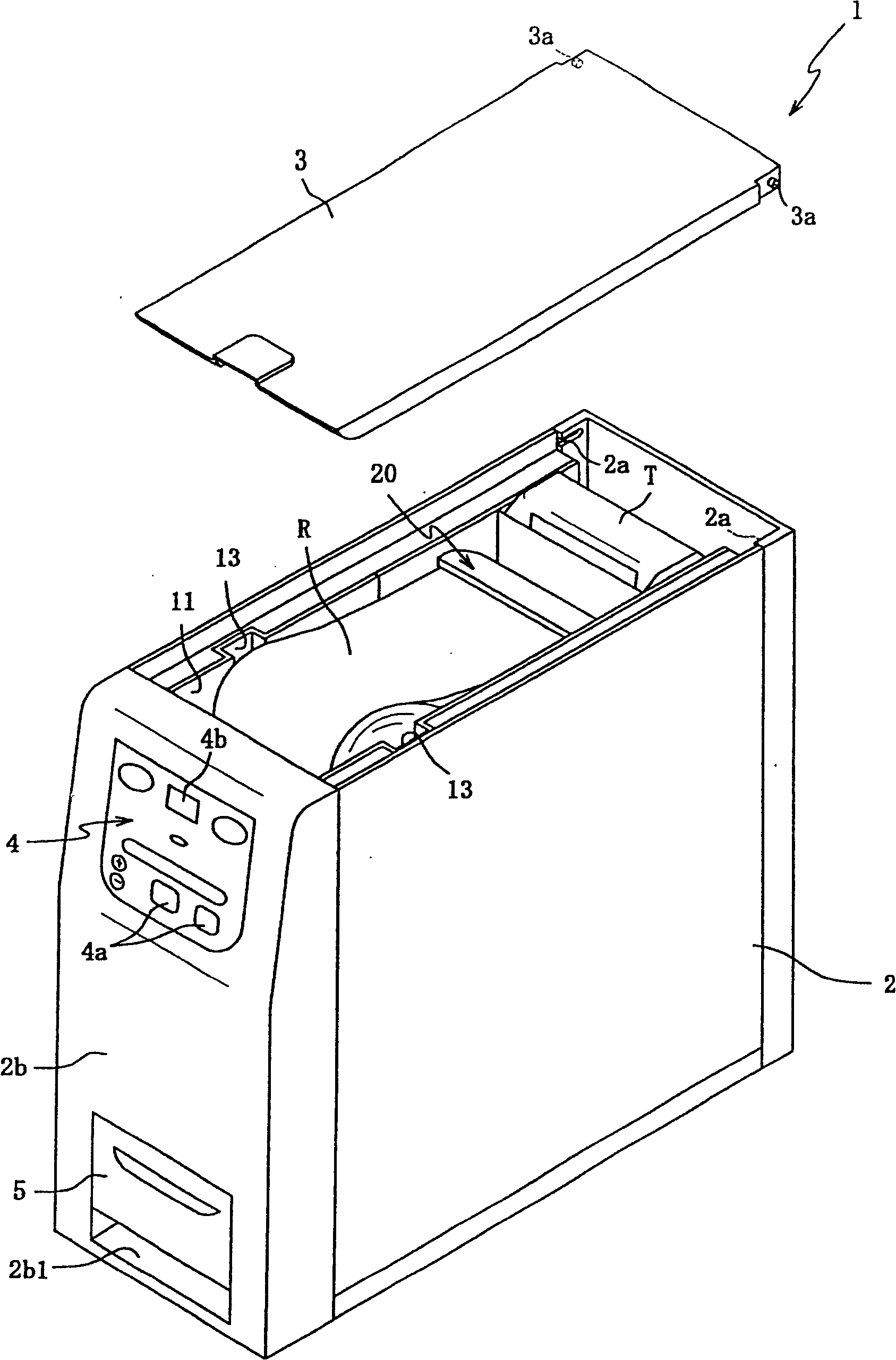

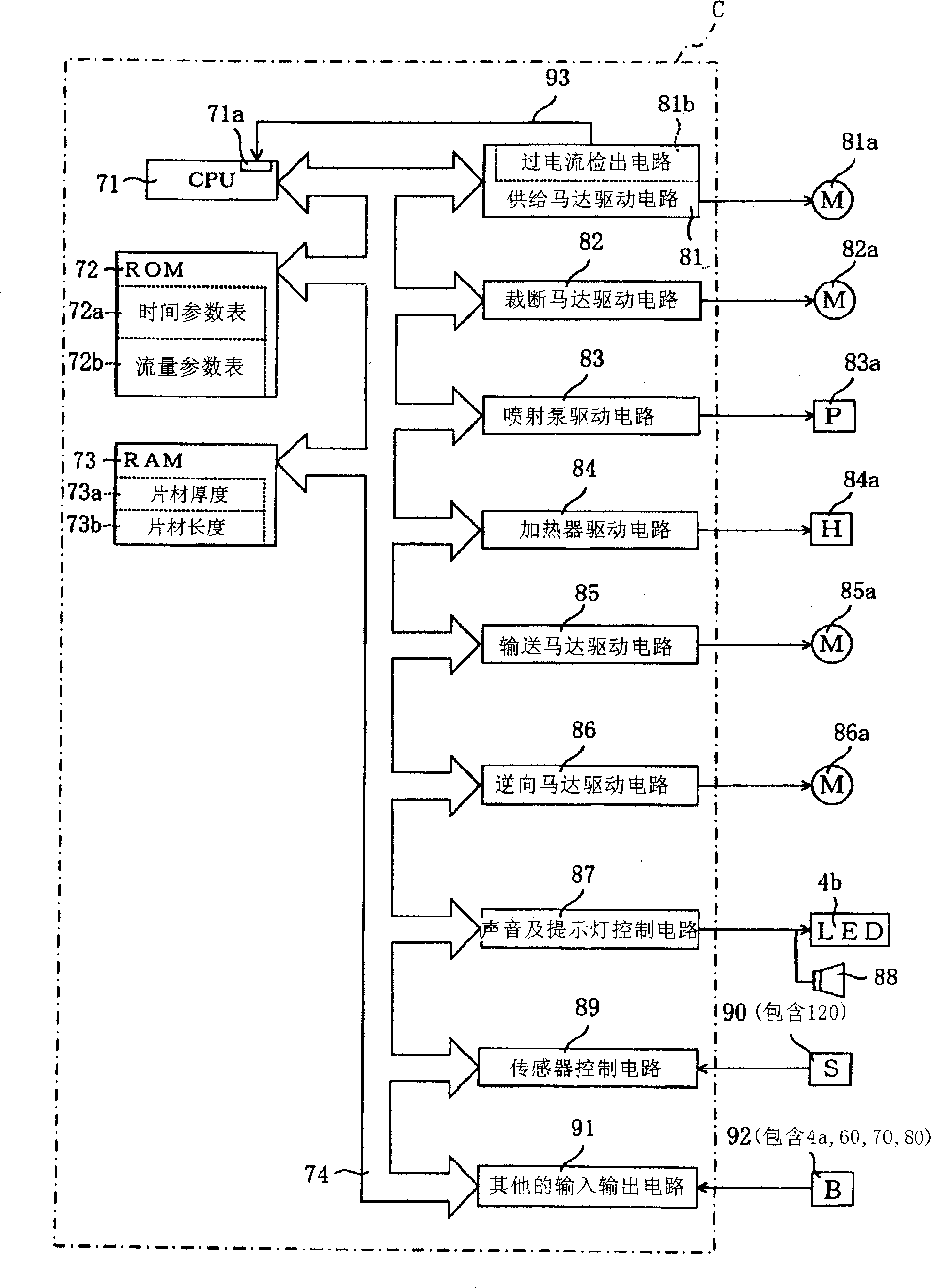

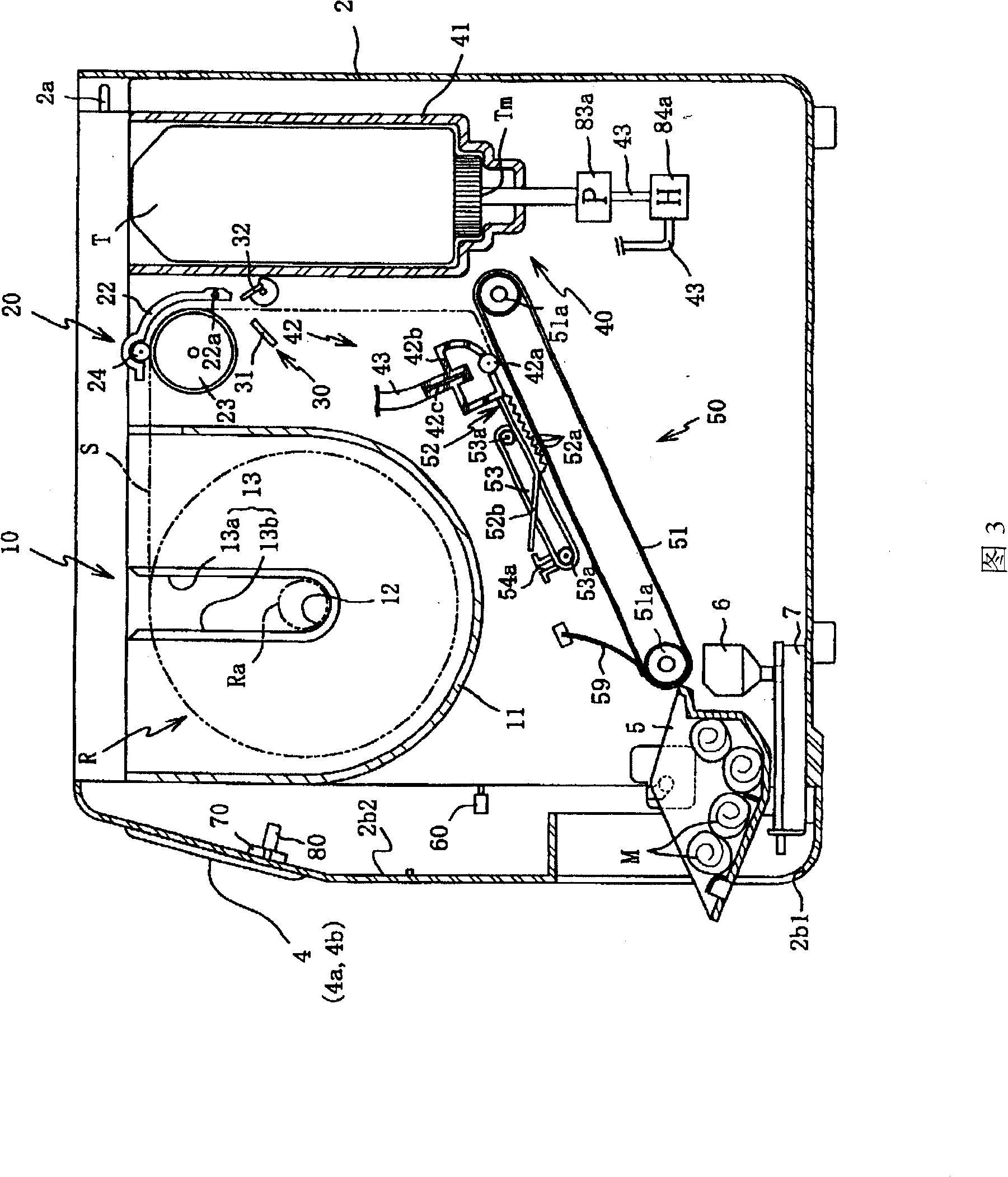

[0085] In the following, suitable practical use examples of the present invention will be described with reference to the drawings.figure 1 It is a side view of the roll towel manufacturing device 1 of one of the application examples of the present invention, and the figure shows the roll towel manufacturing device 1 with the upper cover 3 and the double-purpose tray cover 5 opened. First, refer to figure 1 The appearance structure of the tissue paper manufacturing apparatus 1 will be described.

[0086] The tissue manufacturing apparatus 1 is a device for producing tissue M (refer to FIG. figure 1 As shown, it is mainly composed of a host 2 and an upper cover 3 . The main machine 2 is the frame part of the roll towel manufacturing device 1, and its appearance is a box-shaped structure. The top of the host 2 ( figure 1 above) as figure 1 Shown is an opening structure, and the opening part can be sealed by the upper cover 3 .

[0087] In addition, a pair of rotating shafts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com