Flexible track drilling machine

一种轨道、两轨道的技术,应用在计算机控制、金属加工机械零件、程序控制等方向,能够解决尚未提供大范围工件解决办法等问题,达到编程简化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

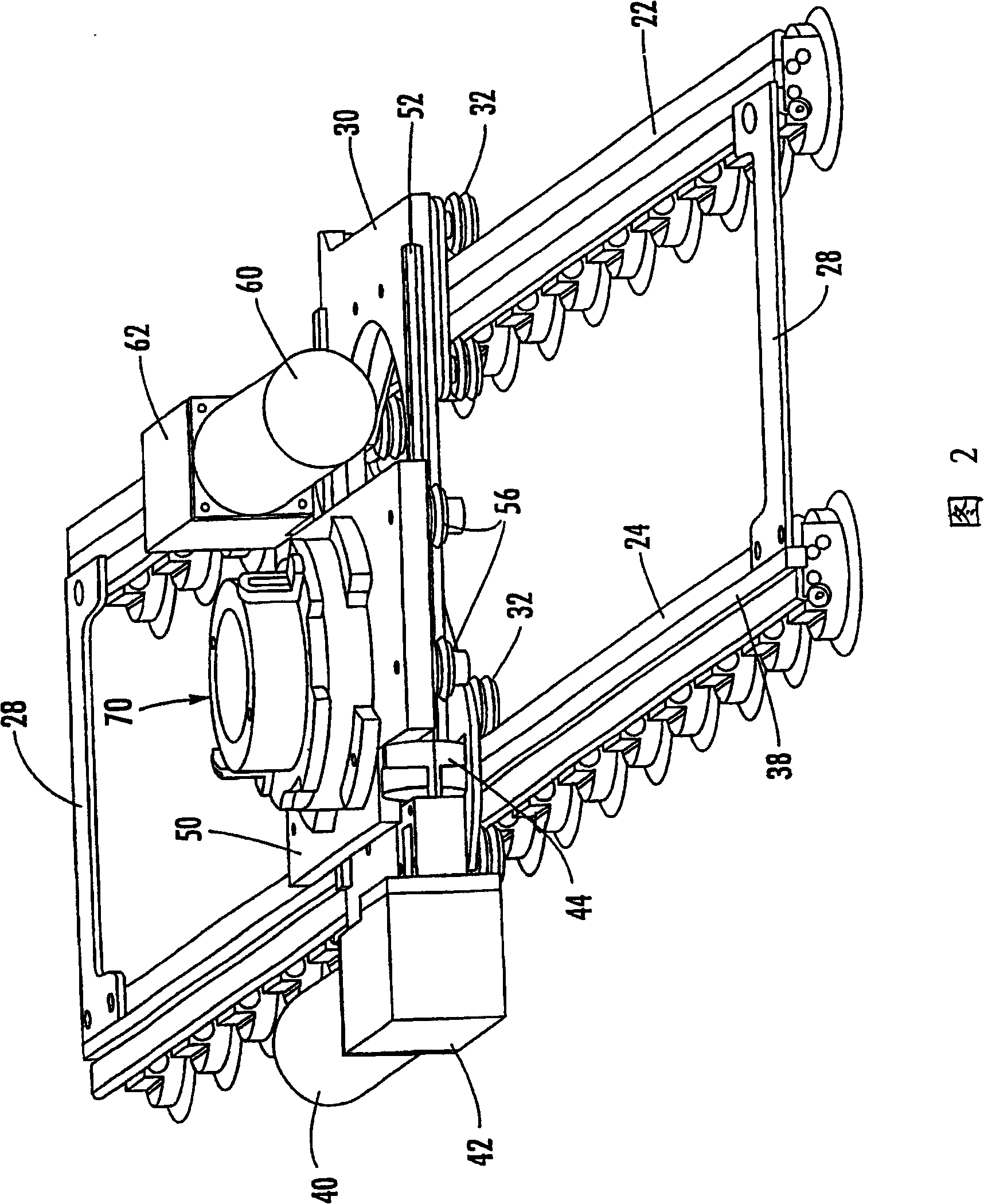

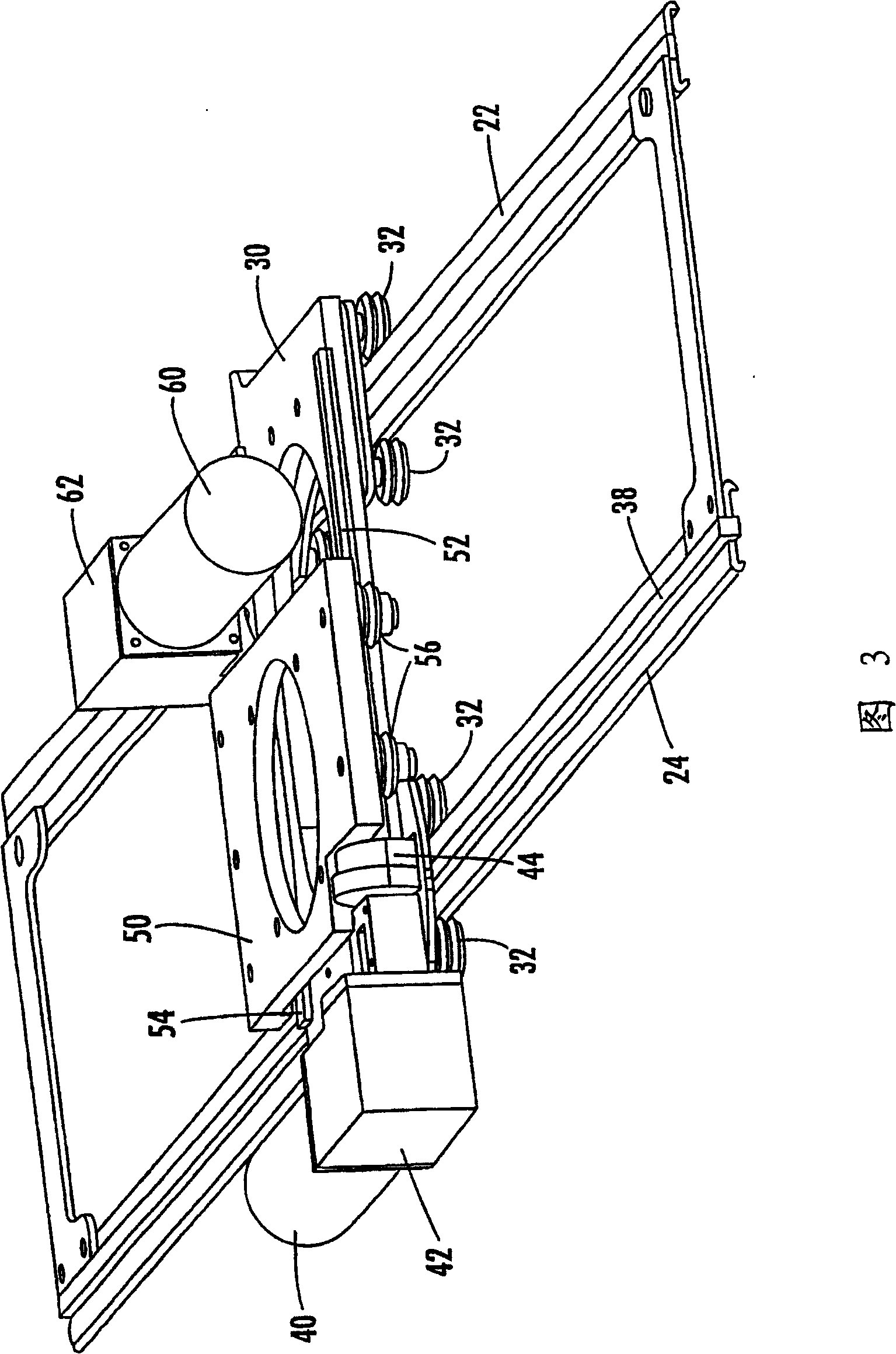

[0022] Hereinafter, the present invention will be described more fully with reference to the accompanying drawings, in which the preferred embodiments of the present invention are shown. However, the present invention can be implemented in many different forms and should not be considered limited to the embodiments described herein; rather, these embodiments are provided so that the disclosure will be thorough and complete, and the present invention The category is fully conveyed to those skilled in the art. The same reference numerals indicate the same elements throughout.

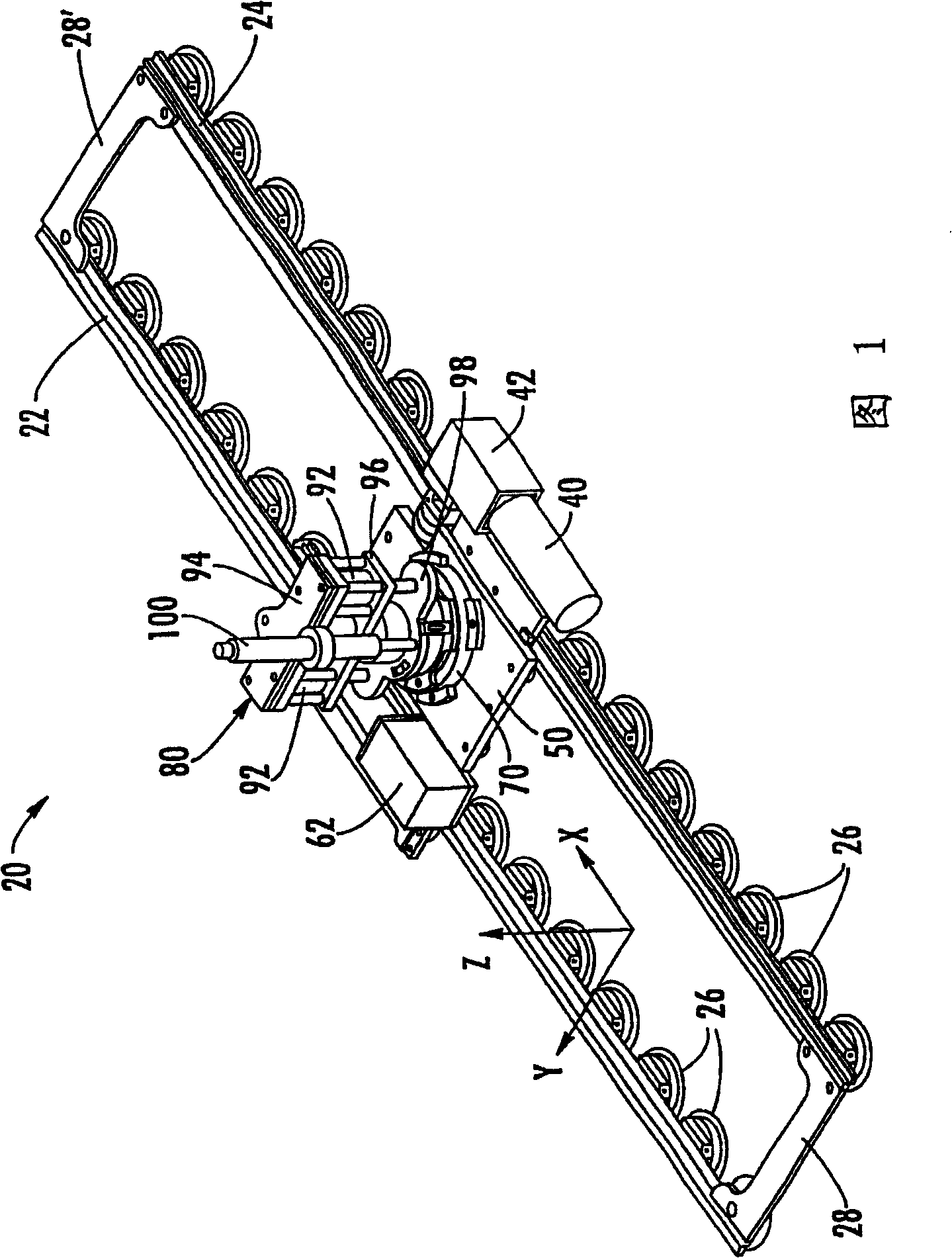

[0023] Referring to Figure 1, this figure shows a machine 20 according to a preferred embodiment of the present invention. This machine includes a pair of rails 22, 24, a plurality of attachment devices, preferably in the form of a vacuum cup holder assembly 26, which are detachably fixed to the pair of rails at spaced intervals along the length of each rail. The rails 22, 24 preferably have a width significa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com