Rolling bearing and material handling and/or construction machine having such rolling bearing

A technology for rolling bearings, construction machinery, used in the field of material handling and/or construction machinery, cranes or tower cable excavators, which can solve problems such as the inclination of the raceway being no longer suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

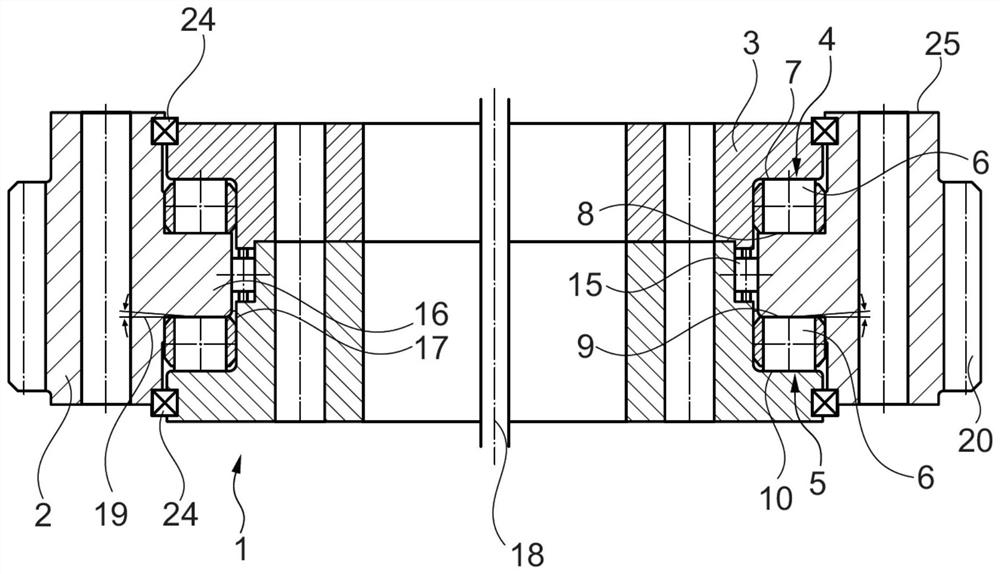

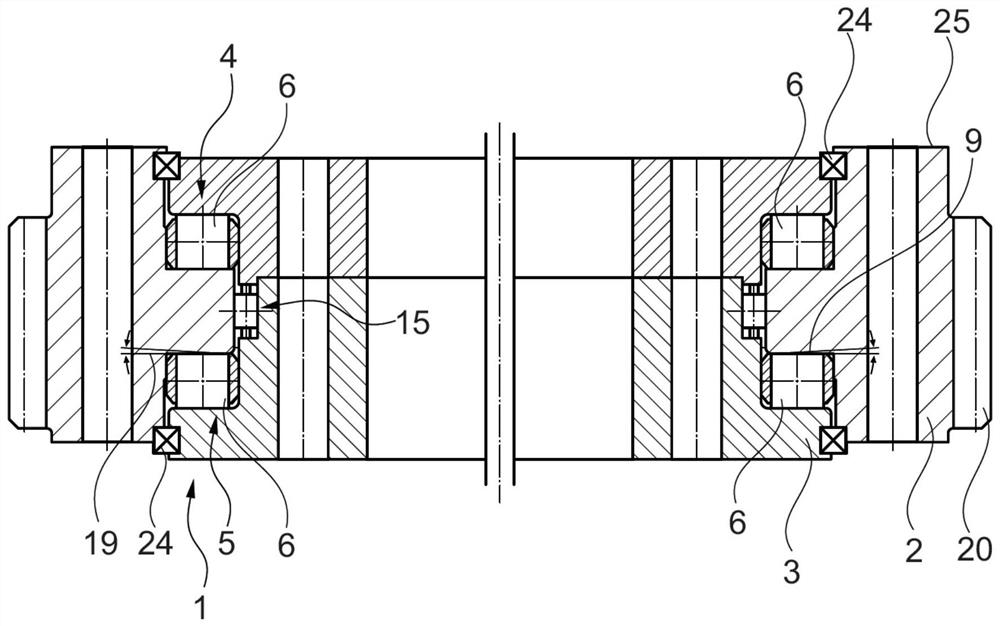

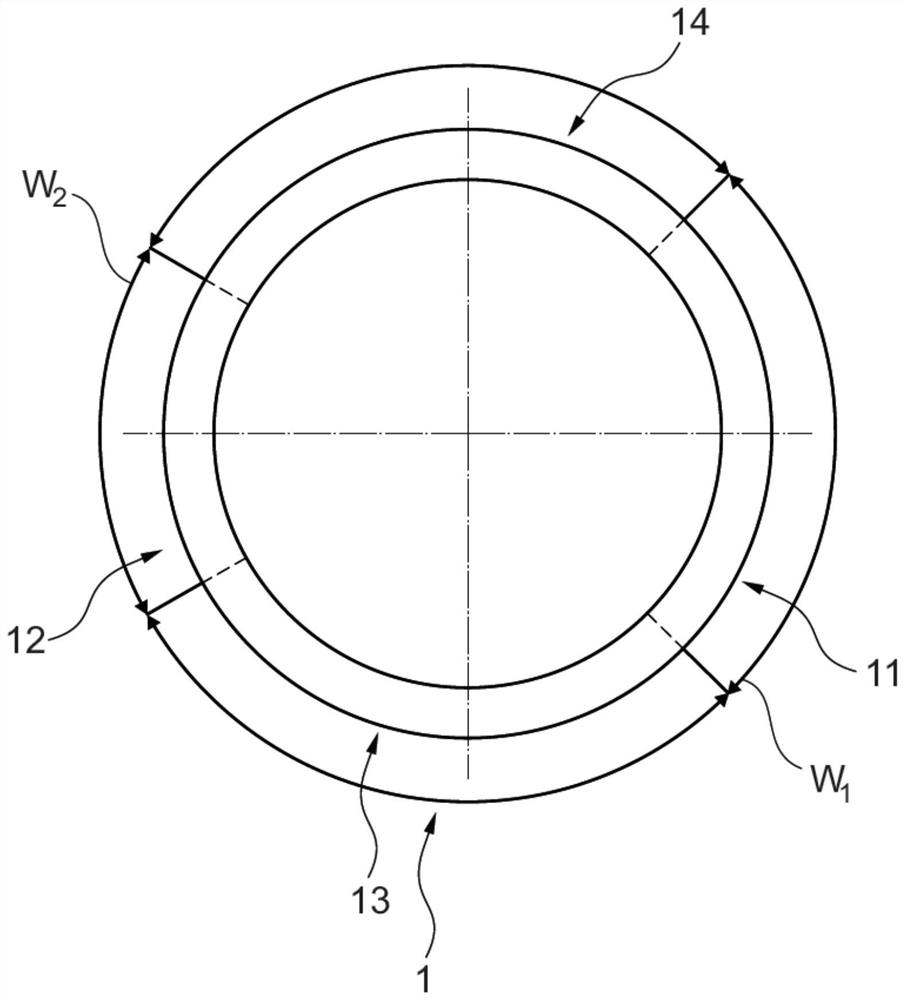

[0038] Such as figure 1 and figure 2 As shown, the rolling bearing 1 may have two rolling loops 2 and 3 that are concentrically concentrically, wherein the rolling bearing 1 may be a rotating mechanism bearing, for example, as a crane 21 or other material handling or construction machinery ( Turning mechanism bearings in tower cable excavators or marine cranes or port cranes. Such as Figure 4 As shown, the rolling bearing 1 can, for example, support the upper structure of the crane to support the vertically rotating mechanism axis 18 in the lower structure, and the lower structure can be constructed, for example, in the form of a truck. The cantilever 22 can be supported on the upper structure, such as a load pickup device 23 in the form of a load hook extends from the cantilever and can rise or decrease. The hanging arm 22 may be expandable and / or tilted and having an extension portion such that the load pickup device and the load on which the boom 22 itself has a lever arm wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com