Device and method for cutting ceramic green block

A technology of shearing device and ceramic blank, which is applied in ceramic molding machines, capacitor manufacturing, manufacturing tools, etc., can solve problems such as poor shearing and complicated devices, and achieve the effect of suppressing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

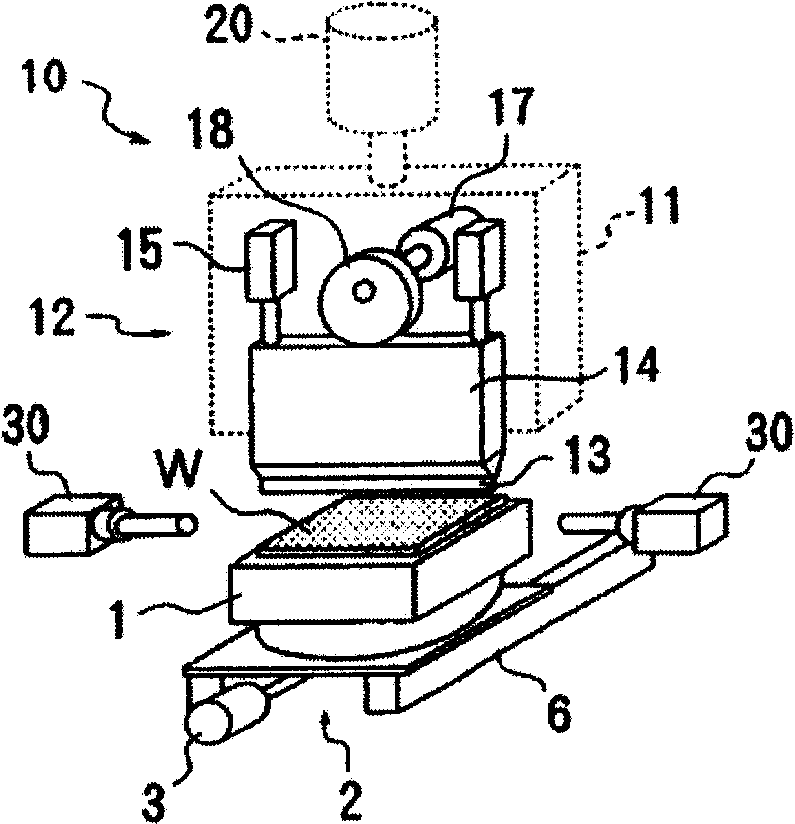

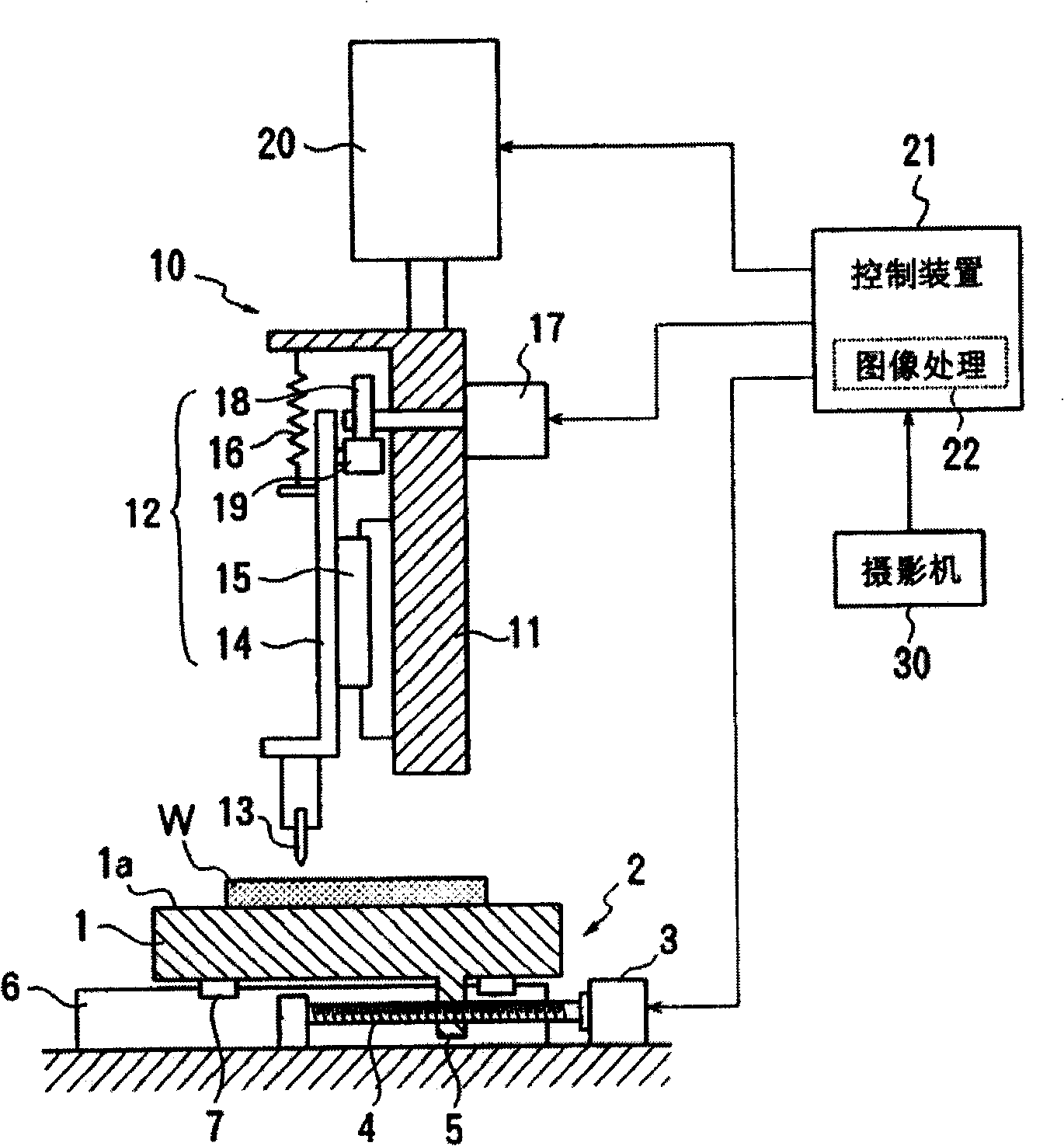

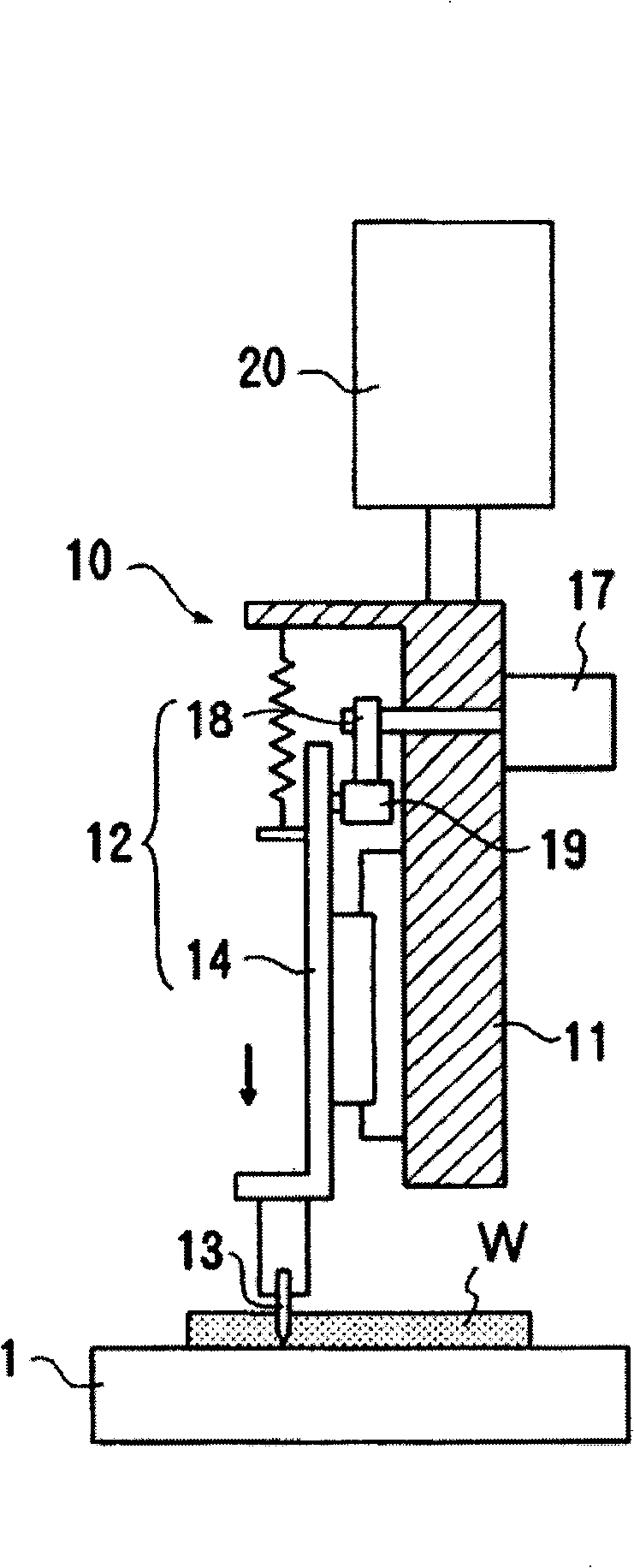

[0031] figure 1 , figure 2 Shown is a first embodiment of the shearing device of the present invention.

[0032] In this embodiment, the case where the ceramic green sheet W in which a plurality of ceramic green sheets are laminated is cut in the manufacturing process of ceramic electronic components is exemplified, but the present invention is not limited thereto.

[0033] The ceramic blank W is placed on the horizontal upper surface (loading surface) 1a of the table 1, and fixed by vacuum suction. The table driving device 2 drives the table 1 horizontally, so that the ceramic blank W reaches a predetermined cutting position. Shear detection marks (not shown) are pre-formed on the side of the ceramic blank W, and the worktable drive device 2 of this embodiment consists of a motor 3, a ball screw 4 installed on the rotating shaft of the motor 3, and a working The nut 5 screwed with the ball screw 4 on the table 1, the guide rail 6 and the slide block 7 that guide the workt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com