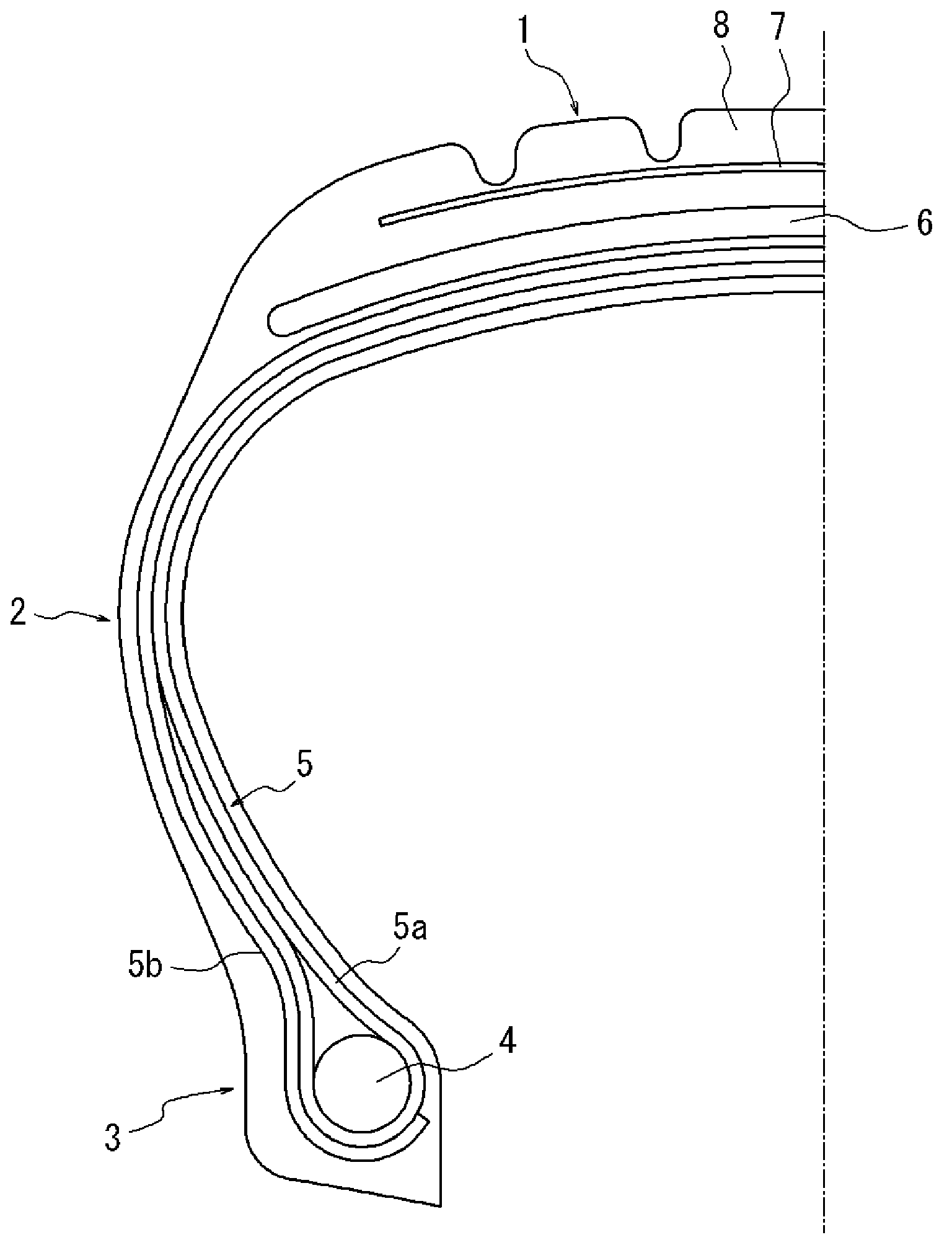

Pneumatic radial aircraft tire

A technology of radial tires and radial tires, applied to the reinforcement layer of pneumatic tires, aircraft tires, tire parts, etc., can solve the problems of damaging the main body of the aircraft, increasing the size of the peeled rubber fragments, etc., and achieve the effect of preventing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

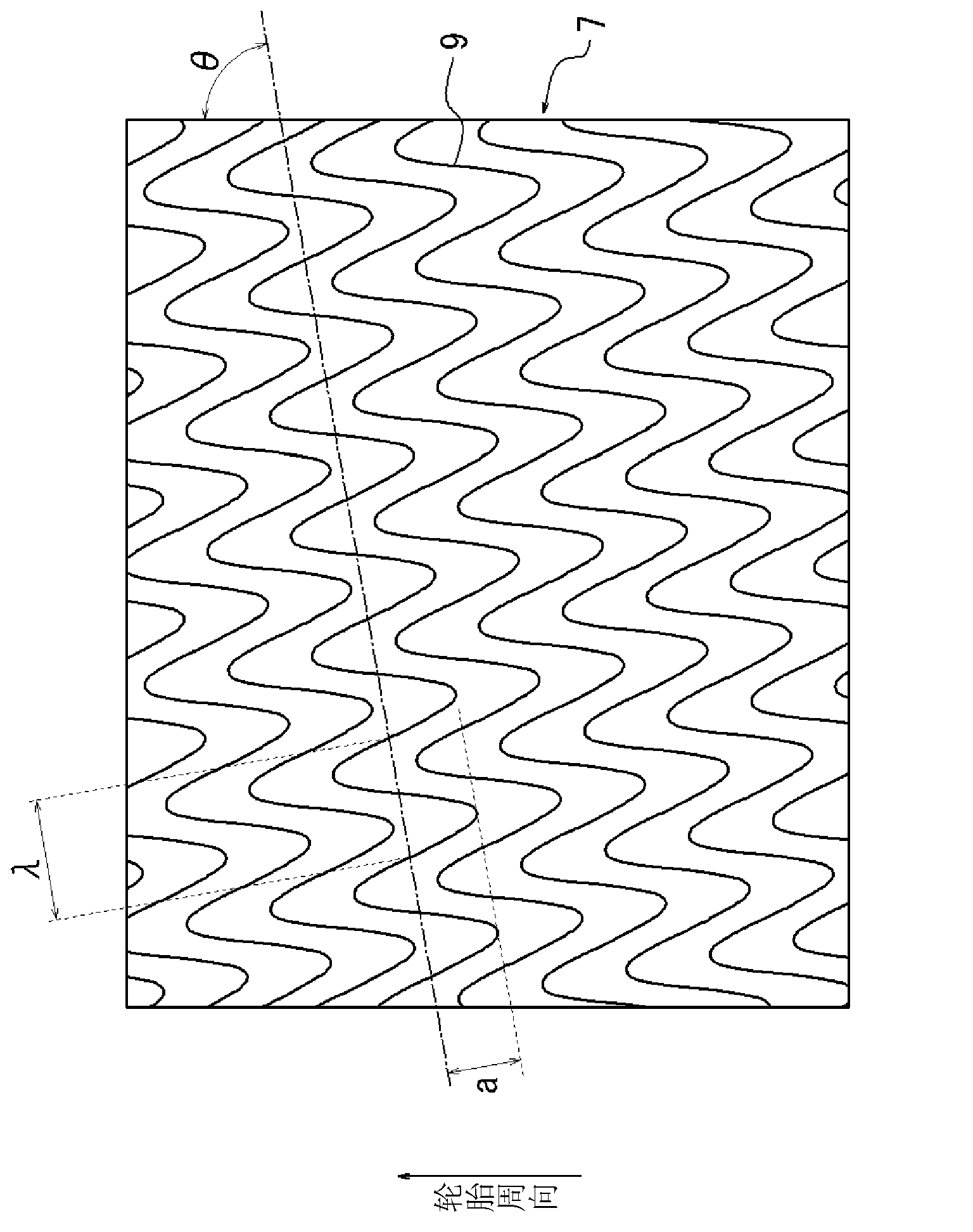

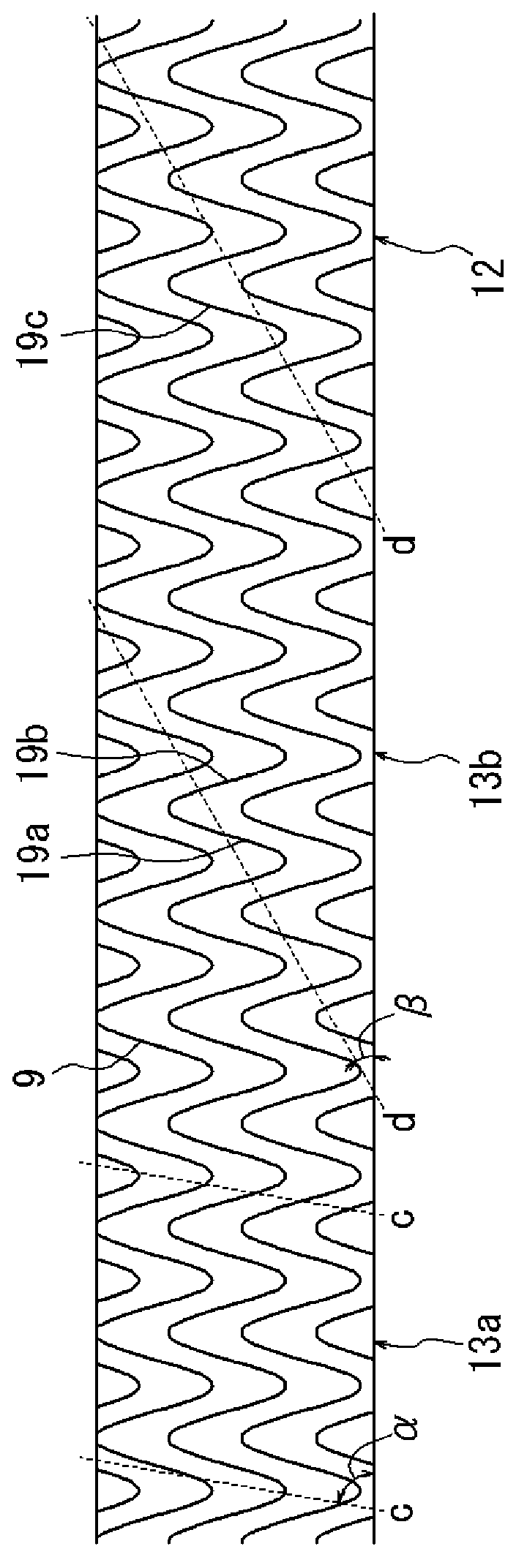

[0048] Note that making a figure 1 and figure 2 The construction shown is a sample tire of dimensions 50 x 20.0R2232PR. As shown in Table 1, the specifications were changed in Example tires 1 to 3 and Comparative example tires 1 to 3, and the peeling resistance of the tread portion and the size of the peeled rubber were measured for each tire.

[0049] Note that the Comparative Example tires did not require structural changes other than the protective layer, and thus were manufactured according to the Example tires.

[0050] Table 1

[0051]

[0052]

[0053] Peel resistance of tread

[0054] Each of Example tires 1 to 3 and Comparative example tires 1 to 3 was mounted to a rim having a size of 50×20OR22 and charged with an internal pressure of 1520 kPa. A central rib width cut was made in each tire from the tread contact patch to the top of the cords in the cover. Next, the start of the test was repeatedly performed under a tire load of 120%, and the number of ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com