Automatic smoothing equipment for curved surfaces of concrete products

A technology for concrete products and curved surfaces, which is applied in the field of automatic smoothing equipment for curved surfaces of concrete products, which can solve problems such as low efficiency, lack of automation, and time-consuming and laborious manual smoothing, and achieve simple construction, reduced workload, and good smoothing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

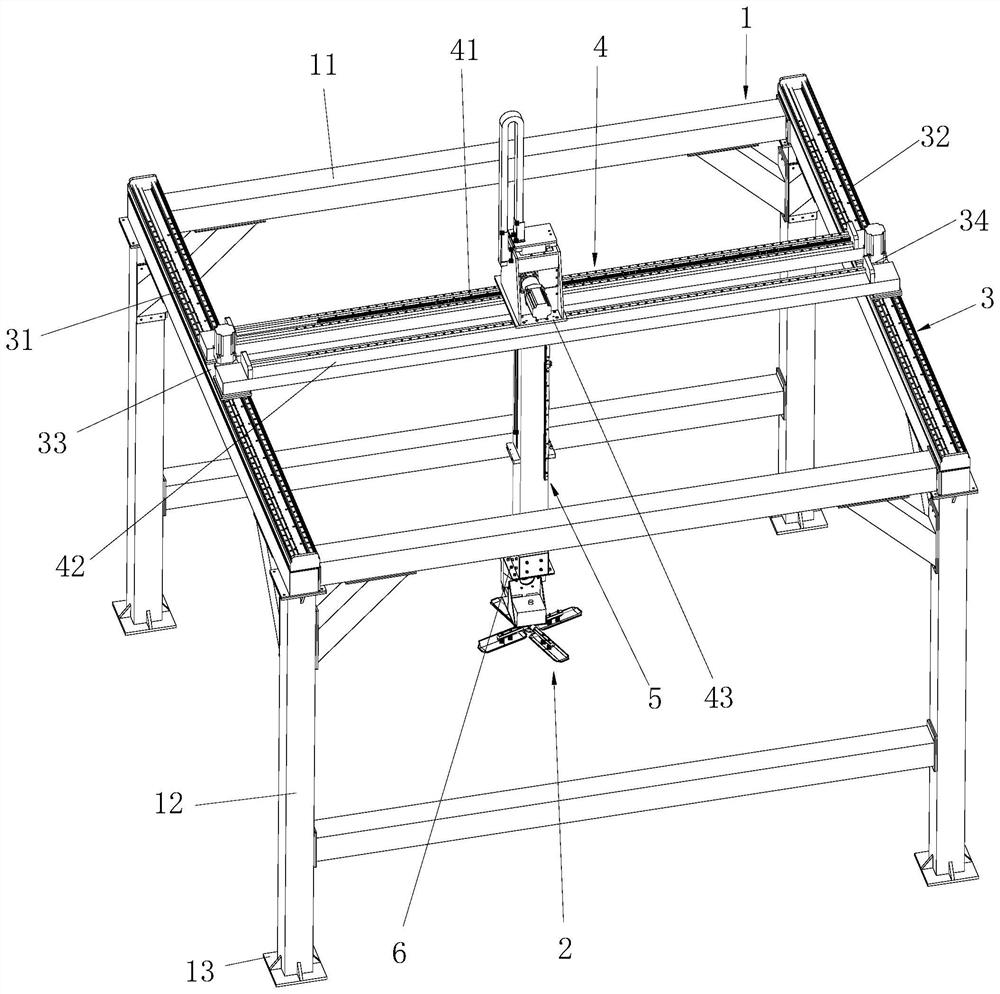

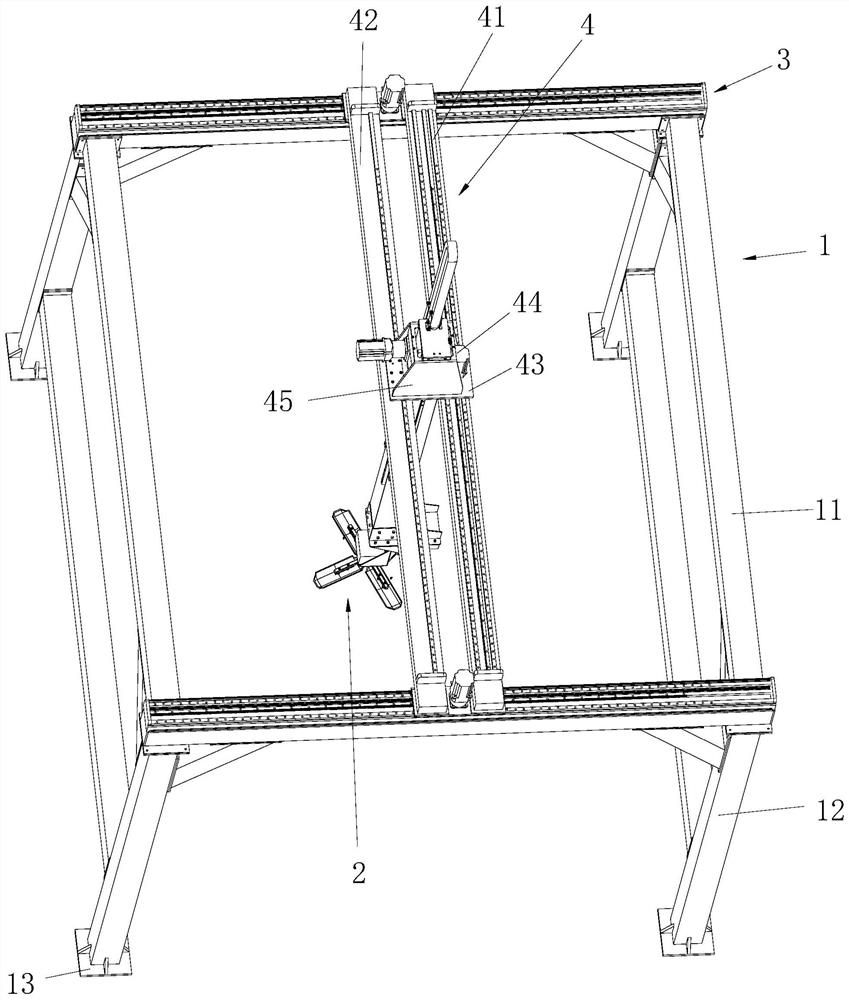

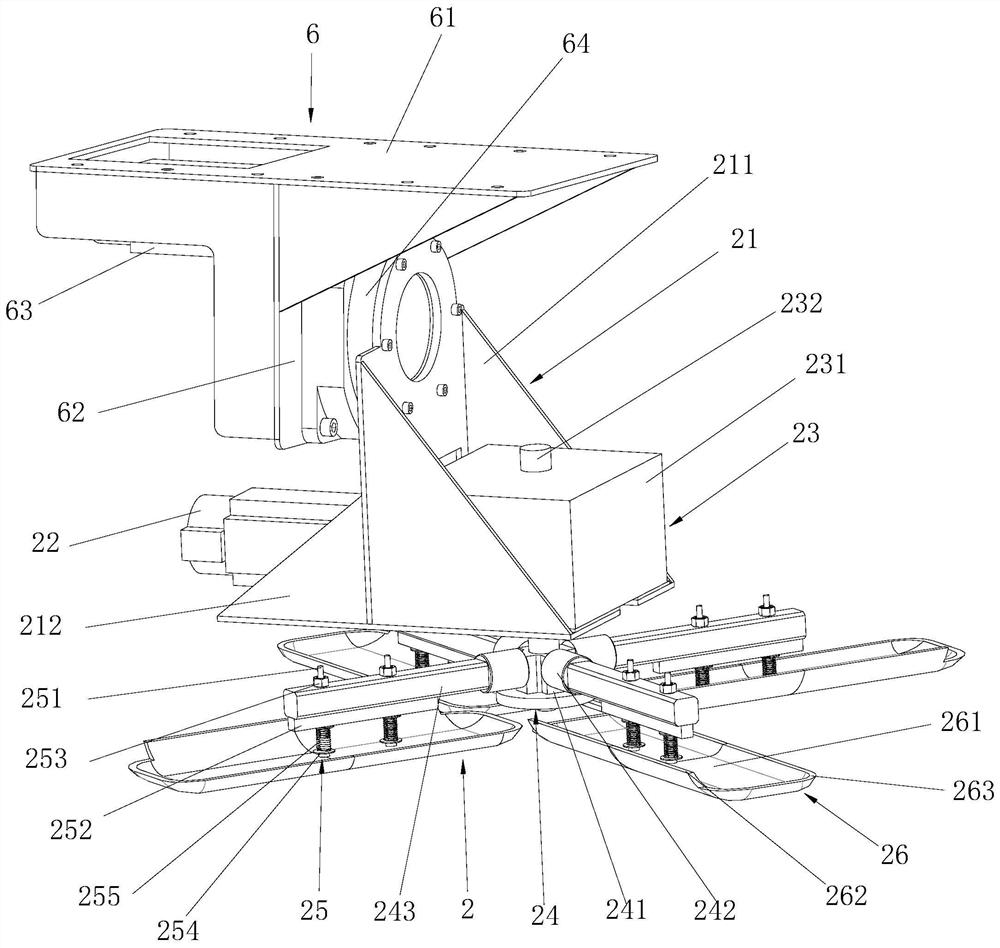

[0038] combine Figure 1 to Figure 6 , an automatic smoothing equipment for curved surfaces of concrete products, comprising a main frame 1 and a leveling mechanism 2, the upper end of the main frame 1 is connected with a longitudinal movement mechanism 3. Longitudinal moving mechanism 3 is connected with horizontal moving mechanism 4, and horizontal moving mechanism 4 is connected with elevating mechanism 5, and the lower end of elevating mechanism 5 is connected with swing positioning mechanism 6, and the lower end of swinging positioning mechanism 6 connects the leveling mechanism 2 that can swing and rotate.

[0039] The main frame 1 includes a first square frame 11 and four first legs 12 connected to the lower ends of the first square frame 11 , and the lower ends of the first legs 12 are connected to the ground through an anchor plate 13 . The vertical movement mechanism 3 comprises a first longitudinal rack track 31 and a second longitudinal rack track 32; the first lon...

Embodiment 2

[0054] In order to realize the automation of the smoothing process of the curved surface of concrete products and improve the efficiency, a five-axis three-linkage automatic smoothing equipment for the curved surface of concrete products is designed. The motors in the leveling mechanism 2, the longitudinal movement mechanism 3, the lateral movement mechanism 4, the lifting mechanism 5 and the swing positioning mechanism 6 are controlled by the troweling equipment control system.

[0055] According to the production requirements, the stroke of the horizontal moving mechanism 4 is 4000mm, the stroke of the vertical moving mechanism 3 is 3200mm, and the stroke of the lifting mechanism 5 is 700mm. The swing positioning mechanism 6 drives the leveling mechanism 2 to rotate in an angle range of -45° to 45°.

[0056] In order to ensure stability and no violent vibration during the movement, the lifting mechanism 5 is designed as a rack and pinion slide table for lifting, and the long...

Embodiment 3

[0062] The above-mentioned automatic troweling equipment is equipped with a leveling mechanism 2, a longitudinal movement mechanism 3, a lateral movement mechanism 4, a lifting mechanism 5 and a swing positioning mechanism, which realizes more efficient and convenient troweling of the arc-shaped concrete products in the mold 7 by the troweling tool. flat. This equipment greatly reduces the time-consuming of the troweling process, and greatly improves the production efficiency of curved concrete products. Workers only need to manipulate the equipment to complete the smoothing of arc-shaped concrete products, which reduces the workload of workers. The manufacturing cost of the equipment is low, the construction is simple, the operation is easy, and the application and production are safe and stable. In this automatic smoothing equipment, the automatic smoothing of the cutter on the arc surface is realized through the five-axis three-linkage, and the tilting design of the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com