Preparation of composite film of nanometer ordered Ca-P compound and collagen

A technology of ordered structure and composite film layer, applied in the direction of electrolytic inorganic material coating, etc., can solve the problems such as the mechanical properties of ceramic materials are difficult to meet the requirements, the biocompatibility and biological activity of metal materials are poor, and the traditional materials are difficult to meet the conditions of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

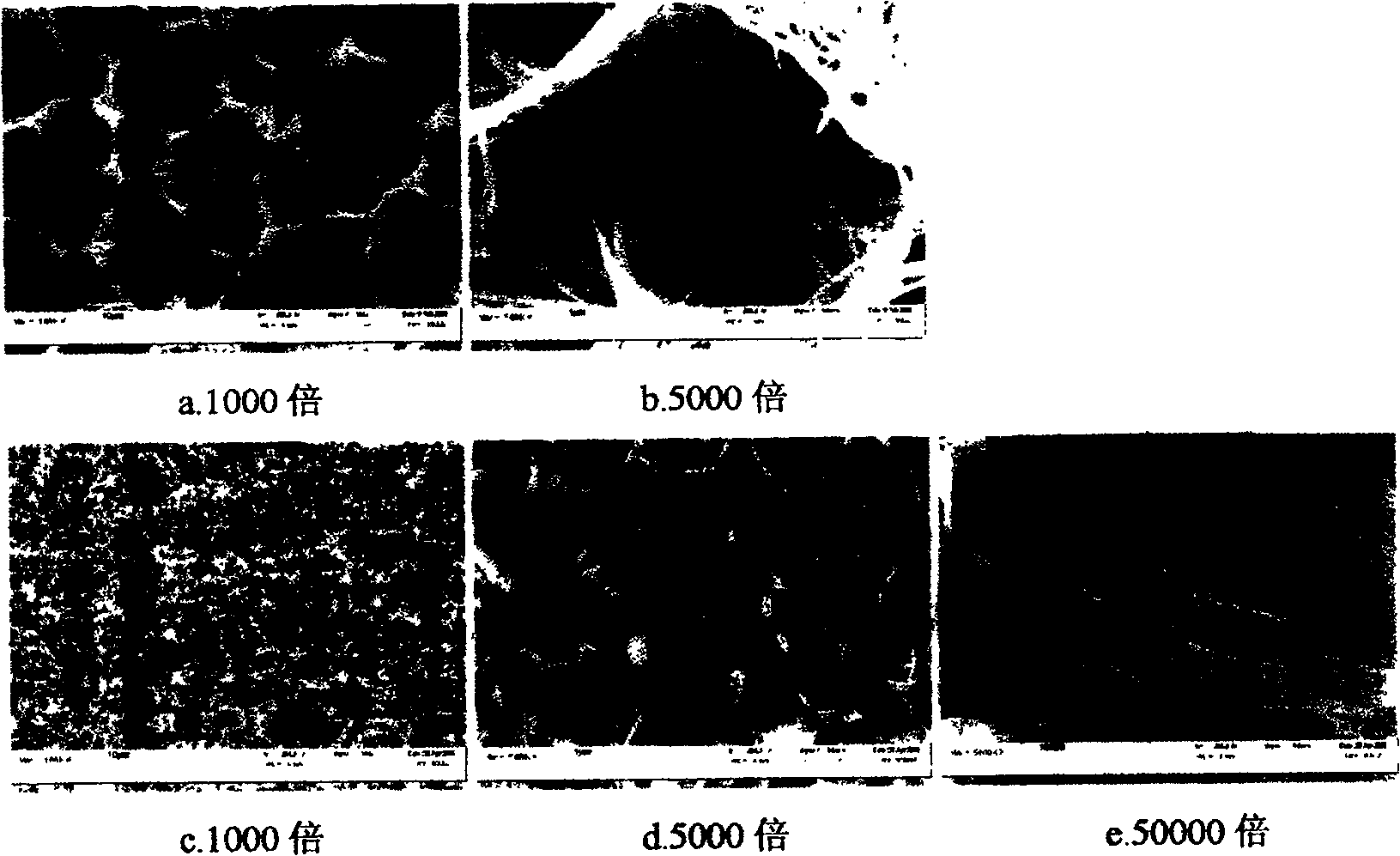

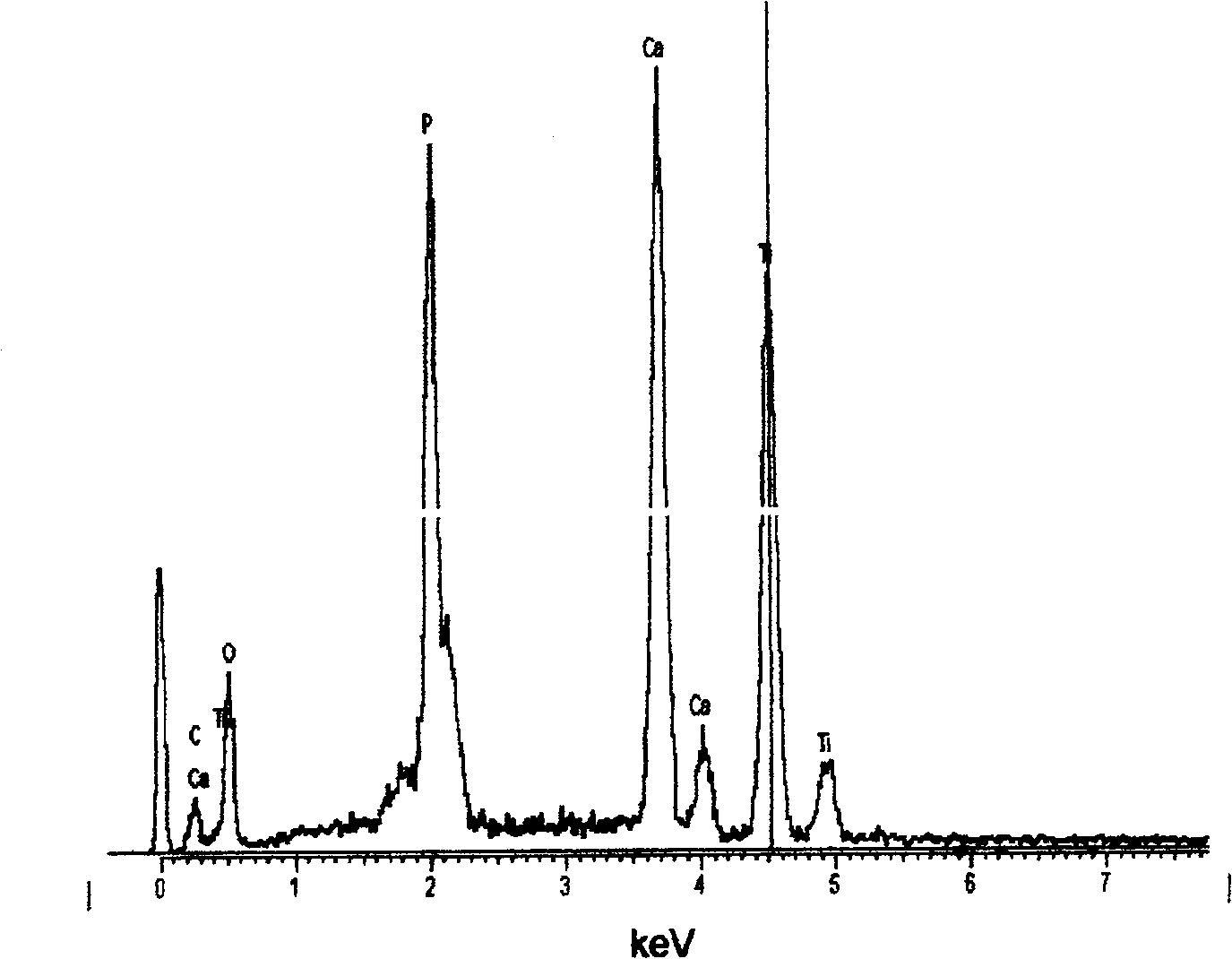

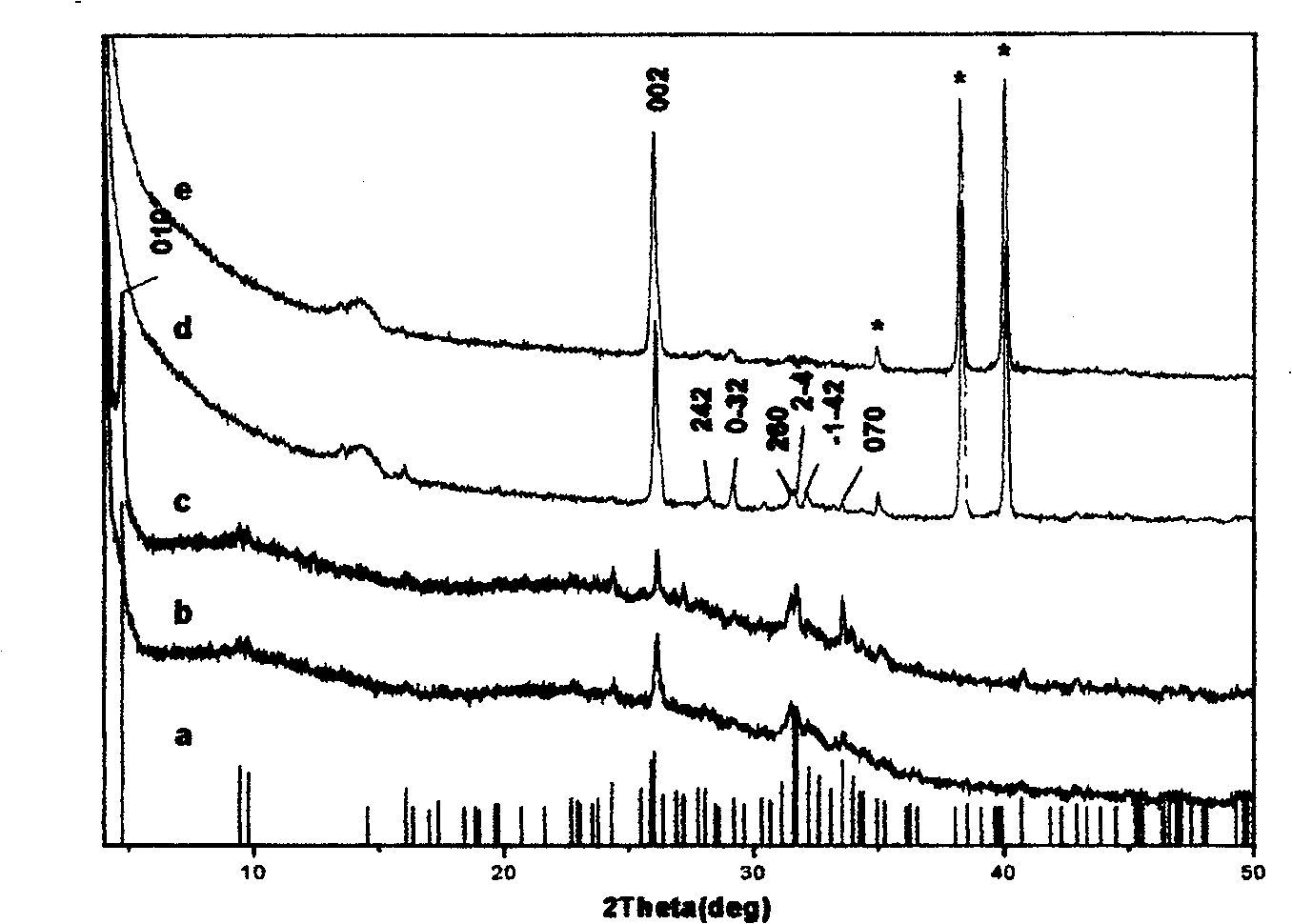

[0020] Embodiment 1: The base material is a pure titanium plate of 15mm×20mm×2mm. After the surface of the titanium plate was polished by sandpaper, it was ultrasonically cleaned in acetone, ethanol and three times in water for 10 minutes, and then cleaned in 10% HNO 3 Pretreatment in +1% HF for 60s, rinse with water three times after taking it out, and dry it for later use. The electrolyte contains 0.042mol / LCa(NO 3 ) 2 and 0.025mol / LNH 4 h 2 PO 4 . Electrolyte pH=4.2, control current density to 0.5mA / cm 2 , for cathodic electrochemical deposition. The temperature is controlled at 65±5° C., and the deposition time is 20 minutes to obtain a microporous nano-ordered octacalcium phosphate deposition layer on the titanium surface. see Figure 1a , b and Table 3.

Embodiment 2

[0021] Embodiment 2: The base material is a pure titanium plate of 15mm×20mm×2mm. After the surface of the titanium plate was polished by sandpaper, it was ultrasonically cleaned in acetone, ethanol and three times in water for 10 minutes, and then cleaned in 10% HNO 3 Pretreatment in +1% HF for 60s, rinse with water three times after taking it out, and dry it for later use. The electrolyte is to add 10ml1mg / ml collagen dispersion to 20ml containing 0.042mol / LCa(NO 3 ) 2 and 0.025mol / LNH 4 h 2 PO 4 Calcium-phosphorus salt solution (operated in an ice-water bath). The 1mg / ml collagen dispersion is to disperse an appropriate amount of collagen in 0.01mol / L acetic acid solution (operated in an ice-water bath). Use 0.05mol / L NaOH to adjust the pH of the electrolyte to 4.2, and control a certain current density to 0.5mA / cm 2 , for cathodic electrochemical deposition. The temperature was controlled at 65±2°C, and the deposition time was 20 minutes, and a microporous nano-ord...

Embodiment 3

[0025] Similar to Example 2, the difference is that the base material is titanium alloy Ti6Al4V. Use 0.05mol / L NaOH to adjust the pH of the electrolyte to 3, and the controlled current density is 0.1mA / cm 2 , for cathodic electrochemical deposition. The temperature was controlled at 53±3°C and the deposition time was 10 min to obtain a microporous nano-ordered CaP / collagen composite deposition layer on the titanium surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com