Direct cooling refrigerator

A refrigerator and direct-cooling technology, applied in the field of direct-cooling refrigerators, can solve the problem of only placing food in a normal temperature environment, and achieve the effects of reducing the amount of initial frost, preventing the amount of frost, and preventing rapid increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

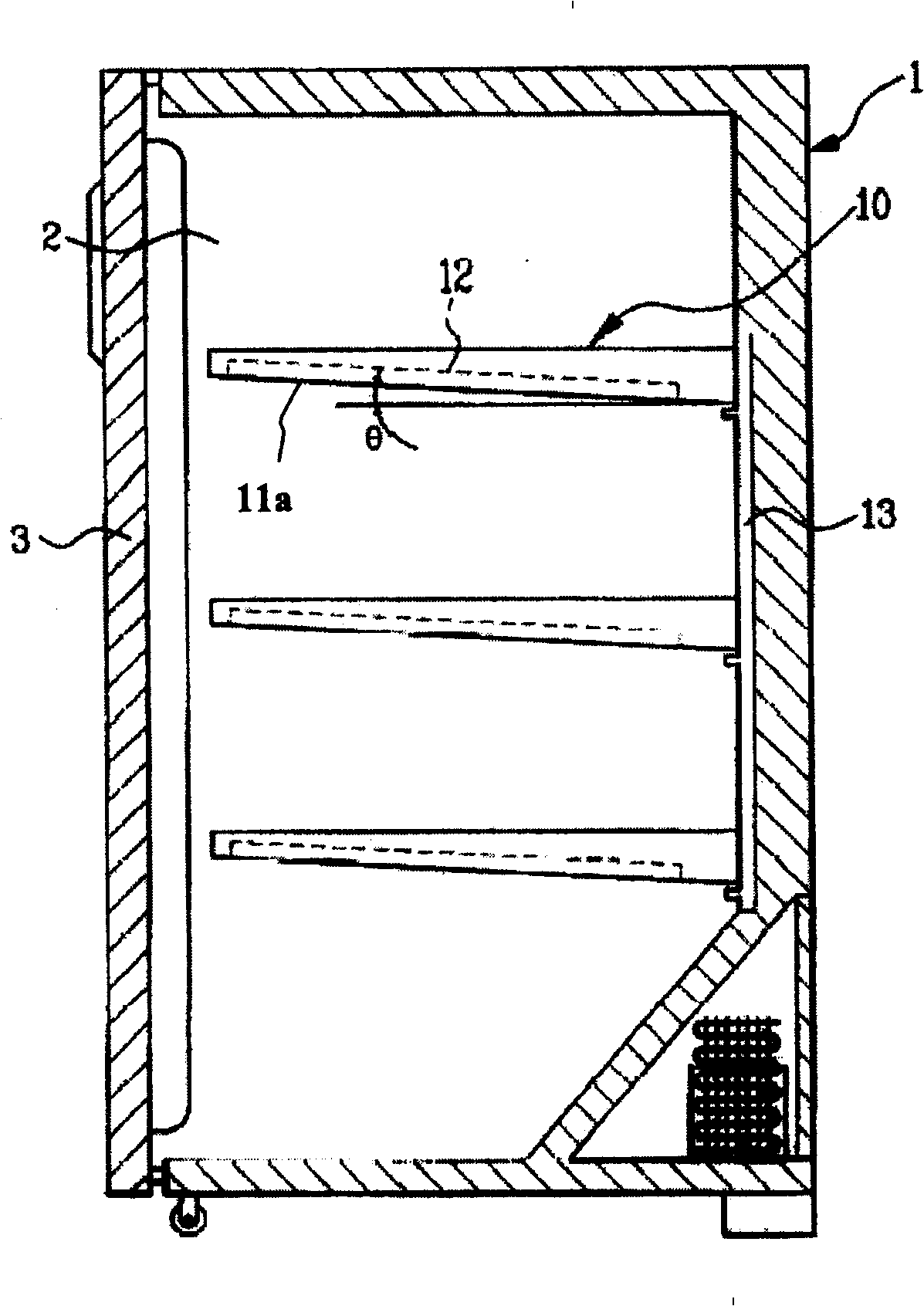

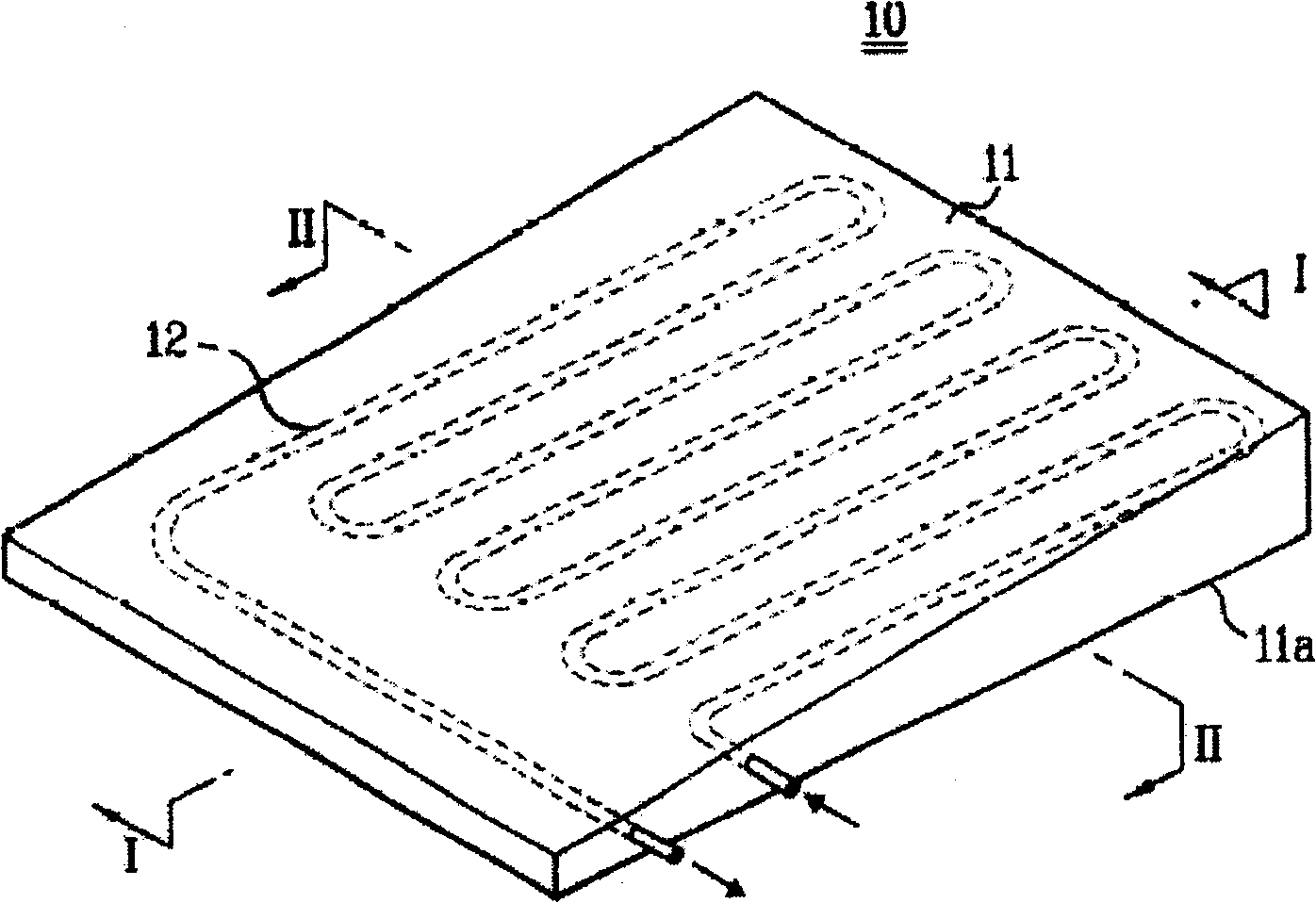

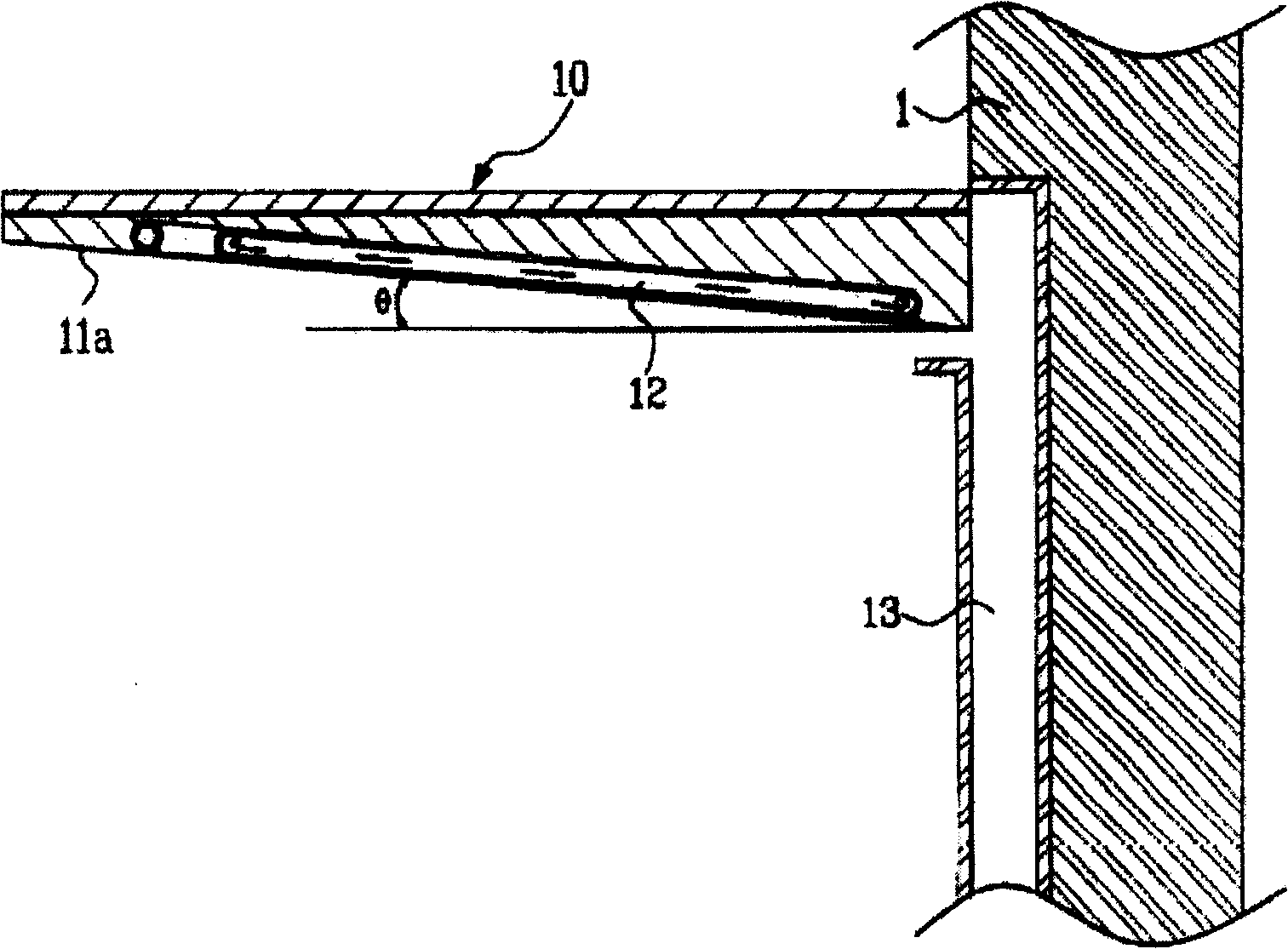

[0029] like Figure 1 to Figure 6 As shown, the box body 1 of the direct cooling refrigerator provided by the present invention has a freezer compartment 2 inside. The direct-cooling refrigerator can only have the freezing chamber 2 or have the freezing chamber 2 and the cold storage chamber, and a pickle preservation chamber can also be set inside it. The freezer compartment 2 is provided with an evaporator 10 capable of dividing its interior into certain spaces. That is, a plurality of evaporators 10 are provided inside the freezer compartment 2 . The evaporator 10 is composed of a heat exchange panel 11 and refrigerant pipes 12 . The heat exchange panel 11 divides the freezer compartment 2 into certain spaces. The inside of the freezer compartment 2 can be provided with multi-layer heat exchange panels 11 . But when the internal space of the freezing compartment 2 is small, only the bottom surface of the freezing compartment 2 is provided with the heat exchange panel 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com