Method for preparing organic light emitting film by electrochemical deposition and application in light emitting device

A technology for electroluminescent devices and luminescent thin films, which is applied in chemical instruments and methods, electrical solid devices, electrolytic organic material coatings, etc., and can solve the problems of no report on the luminous efficiency of thin films and no further preparation of electroluminescent devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Example 1: Synthesis of Light-Emitting Compounds with Charged Active Units

[0121] We only illustrate this patent by taking the synthesis of the compound with the following structure as an example, rather than limiting this patent. The idea or route of synthesis of light-emitting compounds, or the formation of compounds listed in formula (1) above, and the preparation of light-emitting thin films by electrochemical deposition methods are all within the scope of design ideas of this patent.

[0122]

[0123] synthetic route

[0124]

[0125] 1. Synthesis of 2,7-dibromofluorene

[0126] 6g (36mmol) of fluorene, 92mg (1.6mmol) of ferric chloride, and 4ml of liquid bromine were reacted in dichloromethane solvent for 12 hours in the dark. The resulting solid was filtered and recrystallized from ethanol to obtain a white solid product with a yield of 75%. 1 H NMR (500 MHz, CDCl 3 ): δ7.66(s, 2H, Ar-H), δ7.60-7.59(d, 2H, Ar-H), δ7.51-7.49(d, 2H, Ar-H), δ3.87(s , 2H...

Embodiment 2

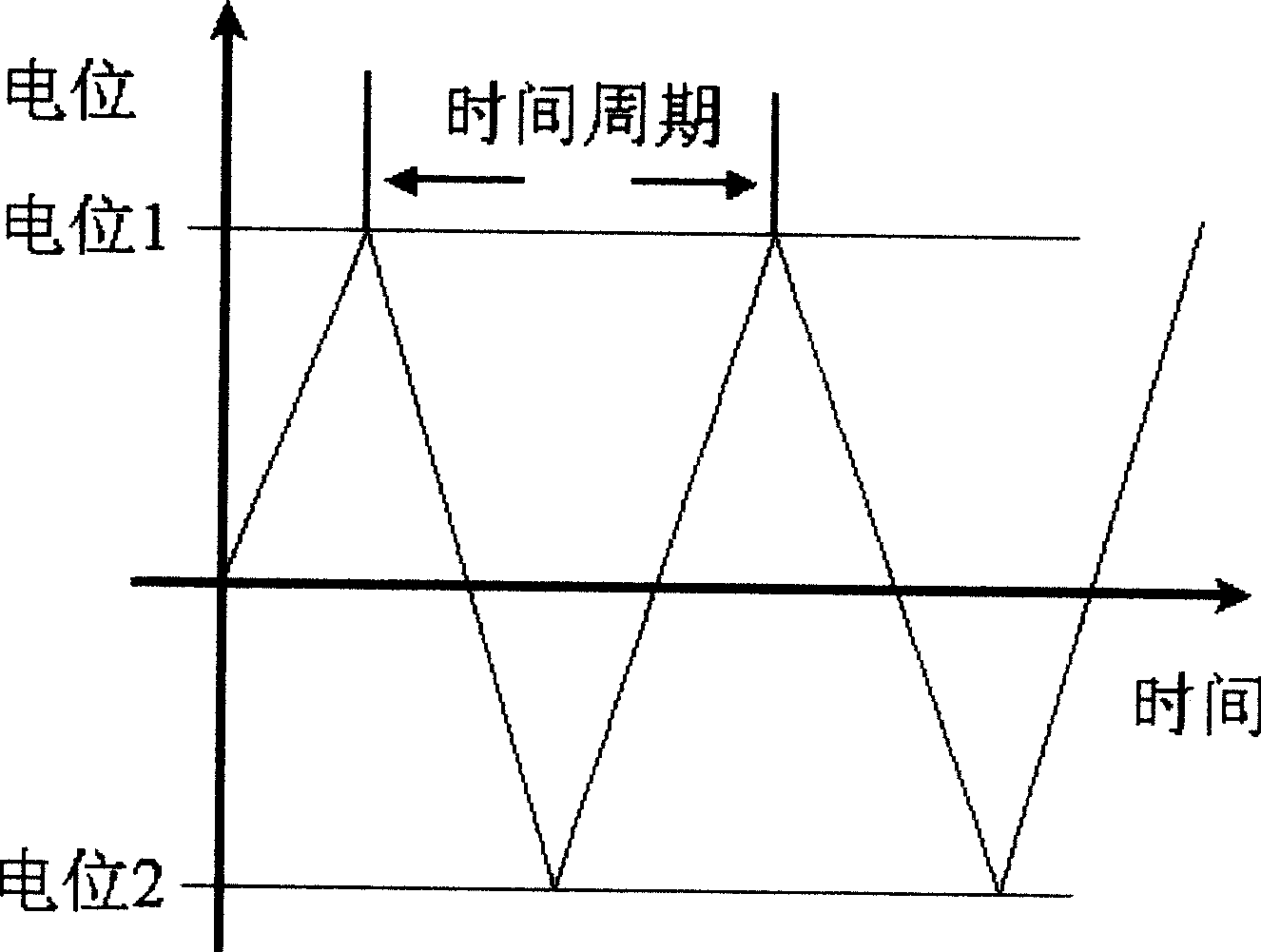

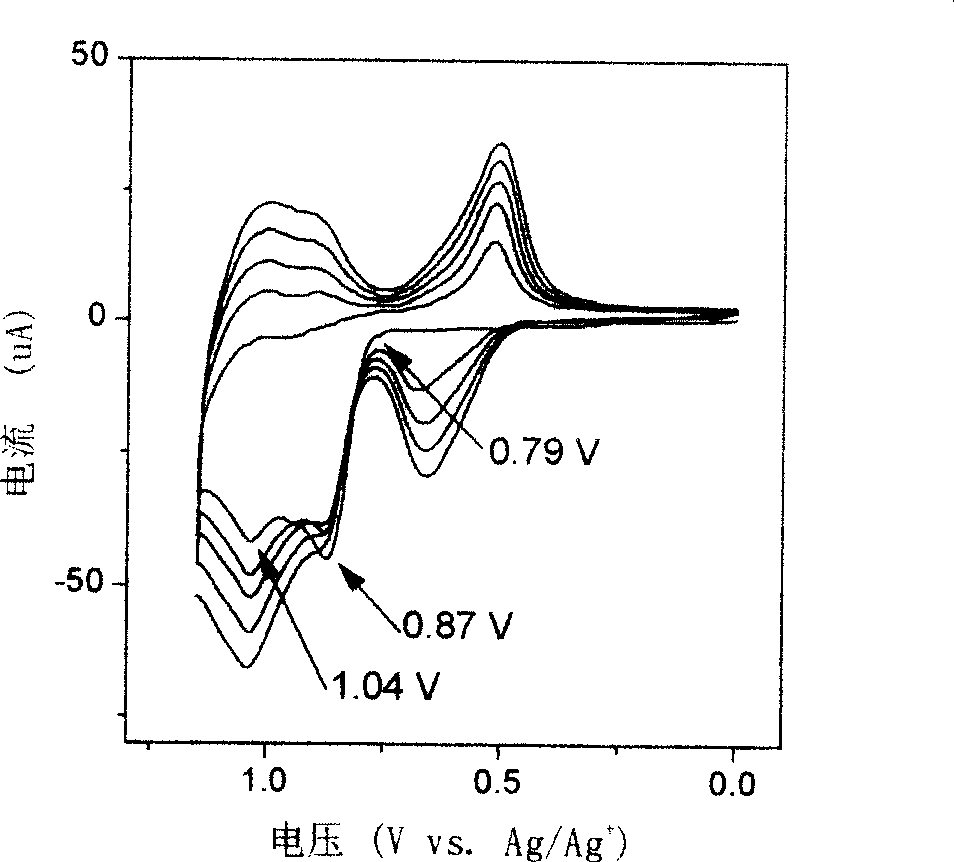

[0141] Example 2: Electrochemical preparation of luminescent film

[0142] 1. Preparation of electrolyte

[0143] The synthesized luminescent molecules linked with electroactive groups were dissolved in the electrolyte solution, and the compound concentration was 1 mg / ml. The supporting electrolyte is tetrabutylammonium hexafluorophosphate, the concentration is 0.1 mol / liter. The solvent is a mixed solution of acetonitrile and dichloromethane with a volume ratio of 2:1. The solute compound prepared in the present invention is slightly soluble in acetonitrile, and in order to increase the concentration of the compound, dichloromethane is added to increase the solubility of the compound.

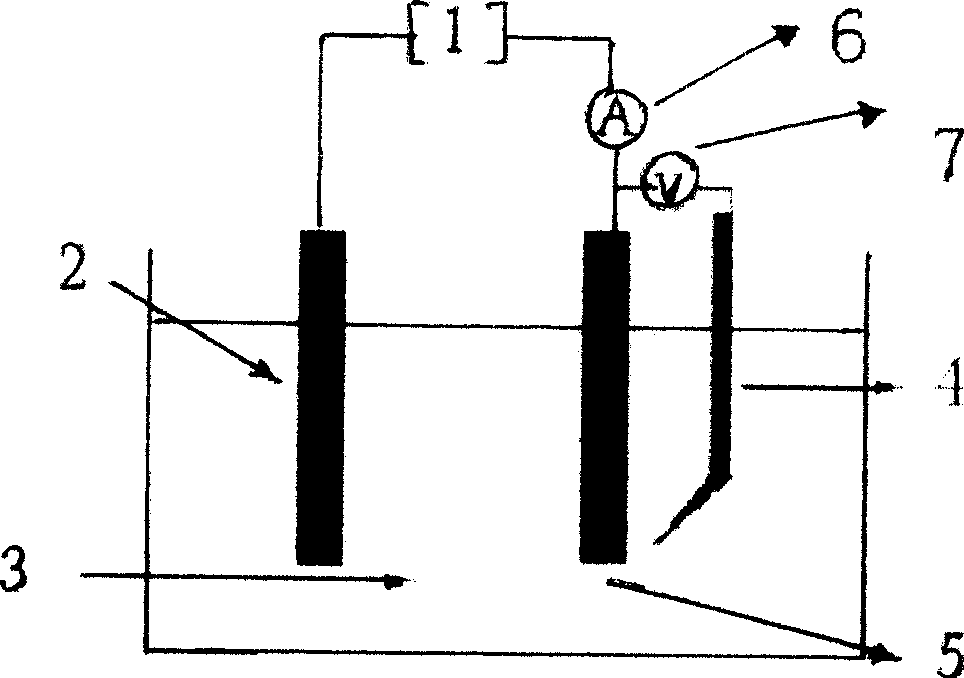

[0144] 2. The use of electrodes

[0145] The working electrode is an ITO (indium tin oxide) electrode with an area of 1 square centimeter to 2 square centimeters. The auxiliary electrode is a platinum wire with a diameter of 1 mm. The reference electrode is silver / silver ions (the solut...

Embodiment 3

[0158] In order to compare with devices made by spin-coating technology, we can also form uniform and flat films through spin-coating processing, so we use a preparation method similar to polymer devices to prepare a structure that is ITO / PEDOT:PSS / TCPC (5mg / ml ) / Ba / Al electroluminescent devices, PEDOT:PSS (polyethylenedioxythiophene / polystyrenesulfonic acid) can enhance hole injection and improve ITO electrodes.

[0159] Fig. 8 shows the variation curves of voltage-brightness-current density (a) and voltage-current efficiency-energy efficiency (b) of a single-layer device prepared by a spin-coating method. This device starts to emit light from 4.5V, with a maximum brightness of 79cd / m 2 , the maximum luminous efficiency is 0.15cd / A, the maximum energy efficiency is 0.078lm / w, and it emits blue light.

[0160] Through the comparison of device performance before and after electrochemical polymerization, we found that although the turn-on voltage of the device prepared after el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com