Nano-crystalline cellulose-based circularly polarized luminescence material, preparation method and application thereof in anti-counterfeiting

A nanocellulose, luminescent material technology, applied in luminescent materials, chemical instruments and methods, coatings, etc., can solve the problem that the chiral circularly polarized luminescence of crystalline nanocellulose has not been developed, and achieve advanced anti-counterfeiting capabilities. , Wide source of raw materials, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Preparation of composite film in crystalline nanocellulose and small organic molecules:

[0048] (1) Add 20g of pulp cellulose (a kind of lignocellulose) to 200mL of sulfuric acid aqueous solution with a mass fraction of 65%, stir at 50°C for 90min for acid hydrolysis, and then add 2000mL of deionized water to terminate the reaction , and after the obtained solution was left to stand, the supernatant was poured off, the separated precipitate was centrifuged using a centrifuge, and the obtained precipitate was dispersed in water after centrifugal washing with deionized water for three times, and the dispersed crystalline nano The colloidal solution of cellulose is injected into the ultrafiltration cup and dialyzed with deionized water until the pH reaches a stable value, and finally the colloidal solution of crystalline nanocellulose is obtained. At this time, the mass fraction of crystalline nanocellulose is 3%. , save for later use.

[0049] (2) Take 5 m...

Embodiment 2

[0052] Embodiment 2: Preparation of crystalline nanocellulose and M1 composite film:

[0053] (1) Concrete operation is the same as embodiment 1 step (1).

[0054] (2) Take 5 mL of crystalline nanocellulose solution with a mass fraction of 3%, stir it for 60 minutes after ultrasonication, pour the solution into a petri dish with a diameter of 5 cm, and self-assemble at 25°C to obtain pure crystalline nanofibers plain film. Prepare an aqueous solution of M1 with a concentration of 1 mM, and attach 100 μL of the solution to one side of the pure crystalline nanocellulose membrane by drip coating. After drying, an outer composite membrane of crystalline nanocellulose and fluorescent objects is obtained. The thickness of the membrane is is 67 μm.

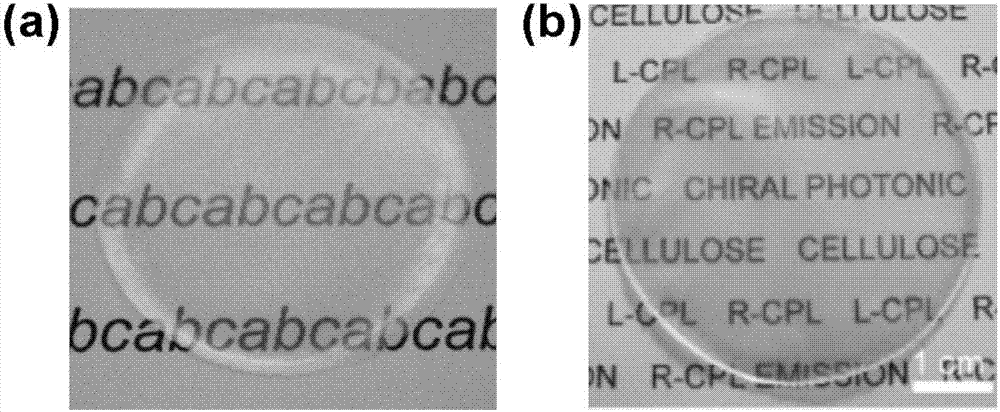

[0055] figure 1 (b) is a photo of the composite film of crystalline nanocellulose and M1 sub-exterior;

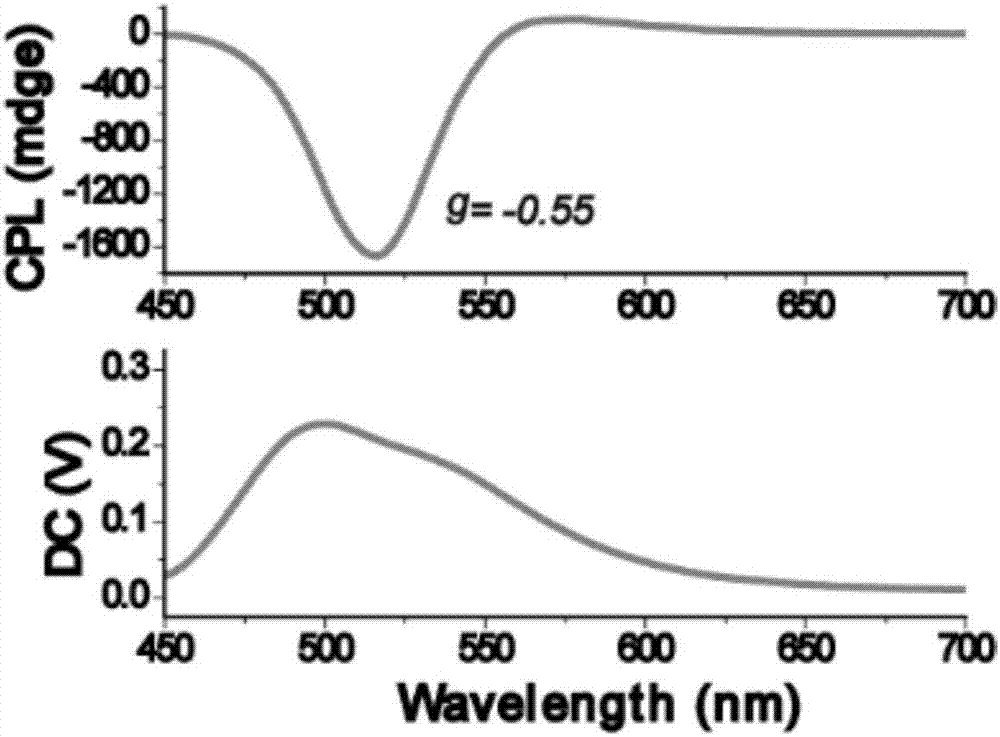

[0056] image 3 It is the circularly polarized emission spectrum of the composite film of crystalline nanocellulose and organic...

Embodiment 3

[0057] Embodiment 3: Preparation of composite film in crystalline nanocellulose and rhodamine B:

[0058] (1) Concrete operation is the same as embodiment 1 (1).

[0059] (2) Take 5 mL of crystalline nanocellulose solution with a mass fraction of 3%, slowly add 100 μL of 2 mM Rhodamine B aqueous solution, and stir for 60 min after ultrasonication to form a uniform and stable mixed solution. Pour the mixed solution into a solution with a diameter of 5 cm Naturally dried in a petri dish at 25°C to form a film. After the water evaporated, the co-assembly of crystalline nanocellulose and fluorescent objects was completed, and an inner composite film of crystalline nanocellulose and rhodamine B was obtained. The thickness is 65 μm. .

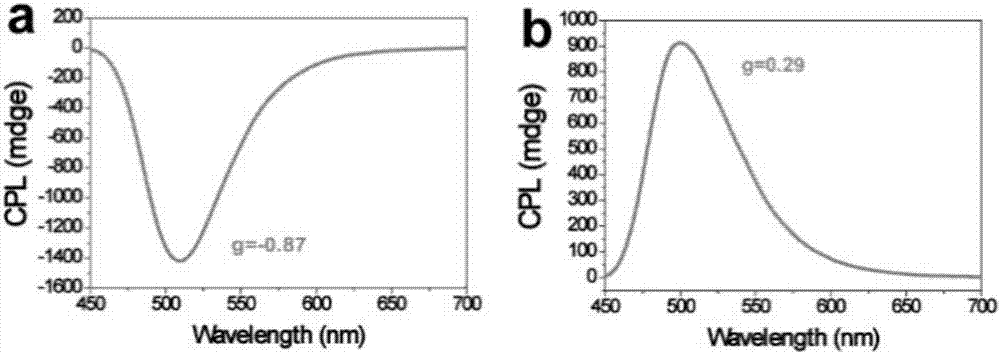

[0060] Figure 4 It is the circularly polarized emission spectrum of the composite film of crystalline nanocellulose and rhodamine B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com