Gas burner

A gas burner and gas technology, applied in the field of cookers, can solve the problems of uneven flame, insufficient intermediate firepower, complex structure, etc., and achieve the effects of increasing the entrance area, large intermediate firepower, and uniform flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

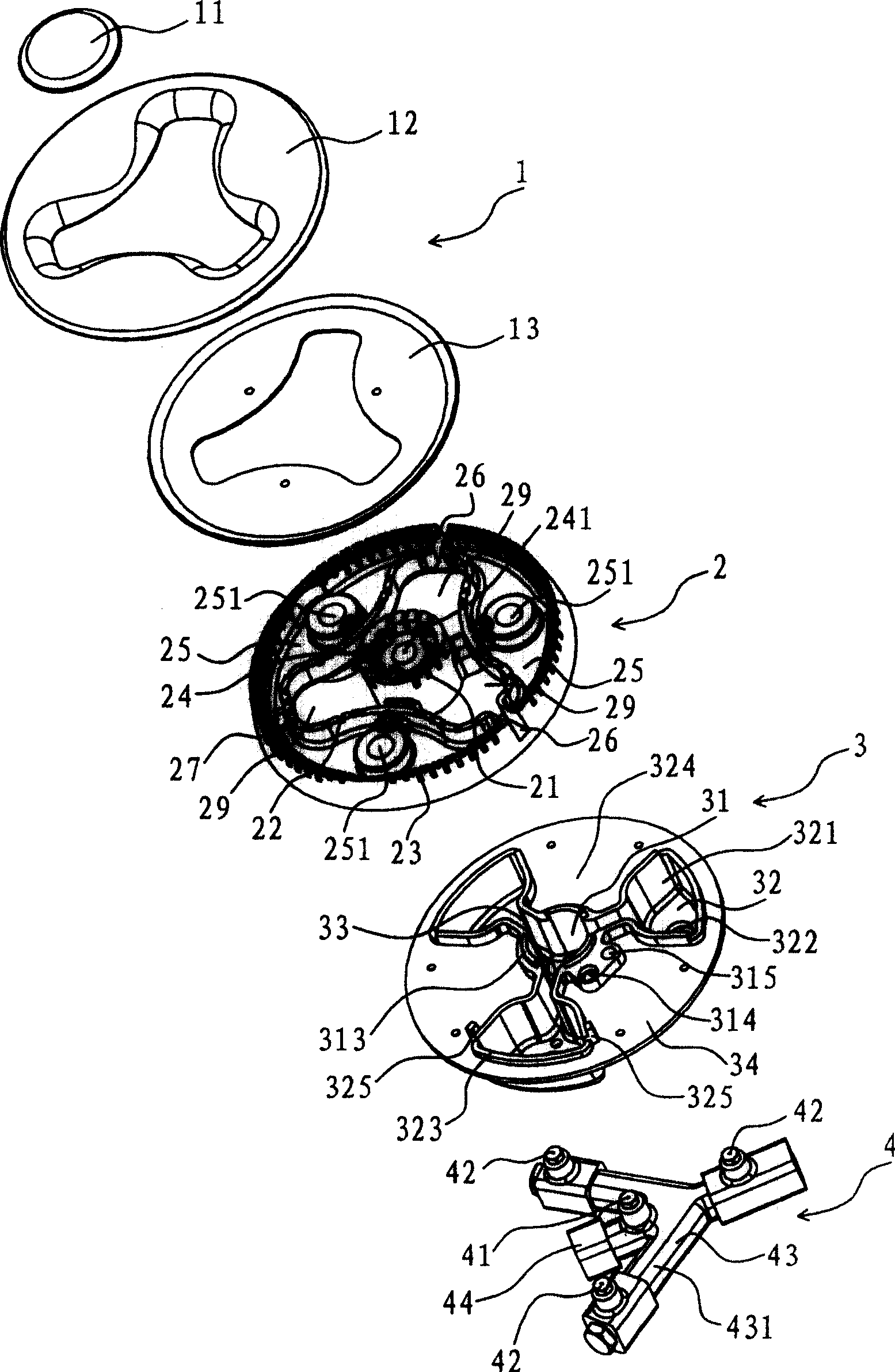

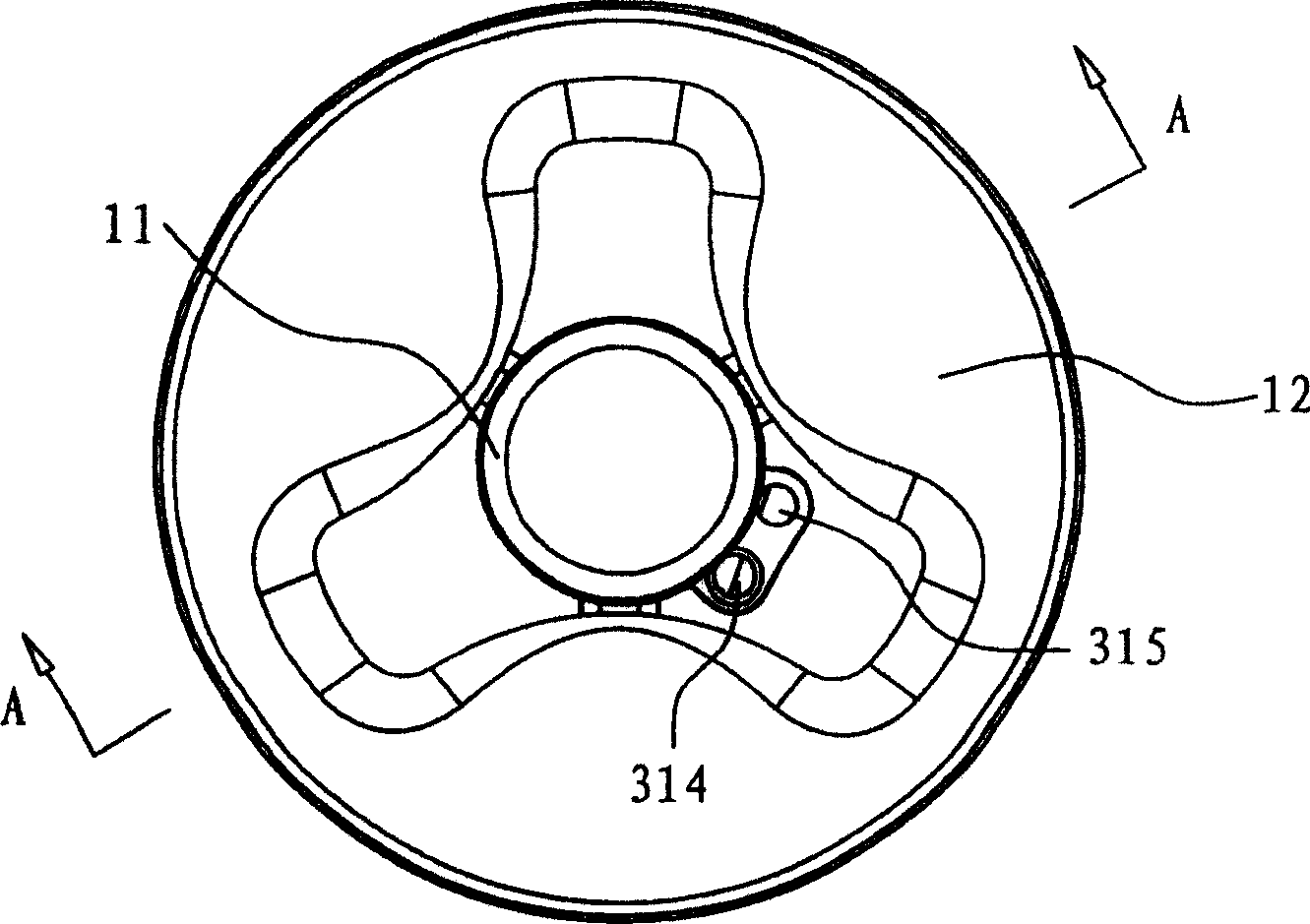

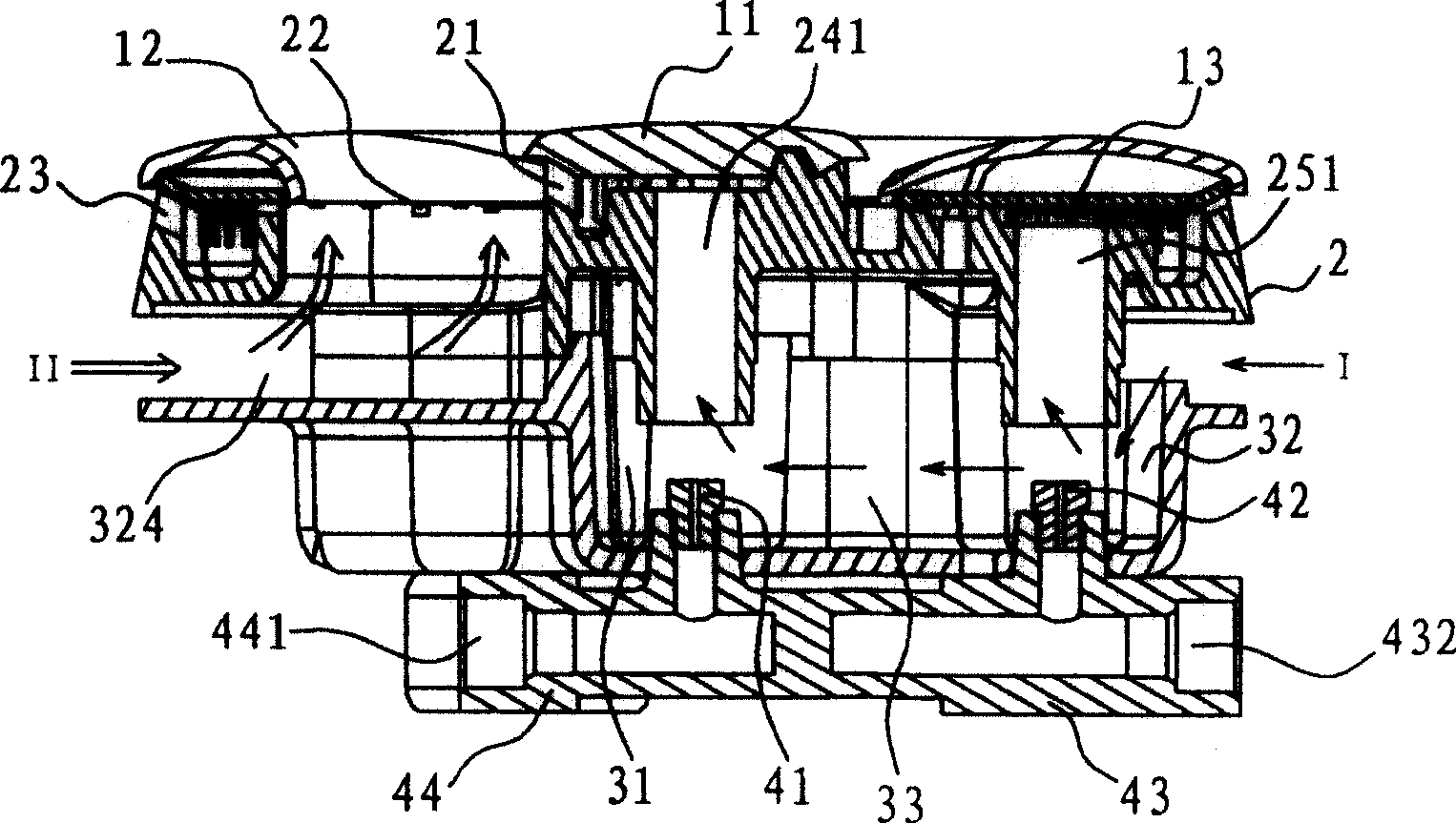

[0026] see Figure 1 to Figure 6 According to a gas burner provided by the present invention, it includes a fire cover 1, a flame injection device 2, a base 3 and an air intake device 4; the fire cover 1 includes a central fire cover 11 and an outer fire cover, and the outer fire cover Fire cover is made up of outer fire cover decorative plate 12 and outer fire cover pressing plate 13, has central fire ring 21, inner fire ring 22, outer fire ring 23 on the described flame-spraying device 2, wherein: described inner fire ring 22 is positioned at the Between the central fire ring and the outer fire ring 23, a central gas mixing chamber 24 is formed in the central fire ring 21, and a central gas mixing pipe 241 is provided in the middle of the central fire mixing chamber 24; Between the fire ring 22 and the central fire ring 21, a plurality of channels 29 for secondary air flow are formed; at least three evenly distributed channels are formed between the inner fire ring 22 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com