Stage filmstrip machine

A technology for slides and film winding, applied in the field of stage slide film winders, can solve the problems of low film changing efficiency, slow film changing speed, low efficiency, etc., and achieve the effect of improving work efficiency and avoiding time difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

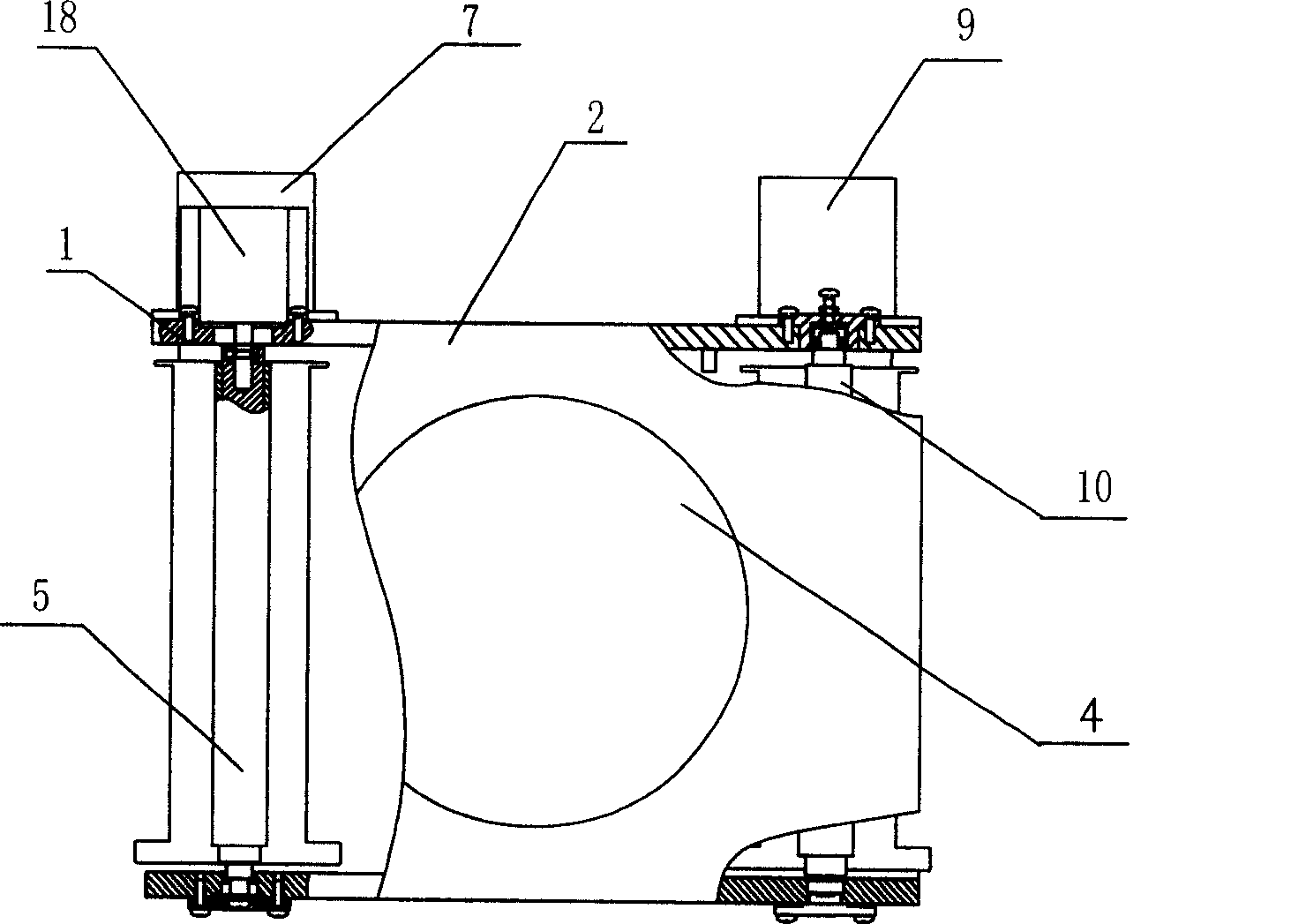

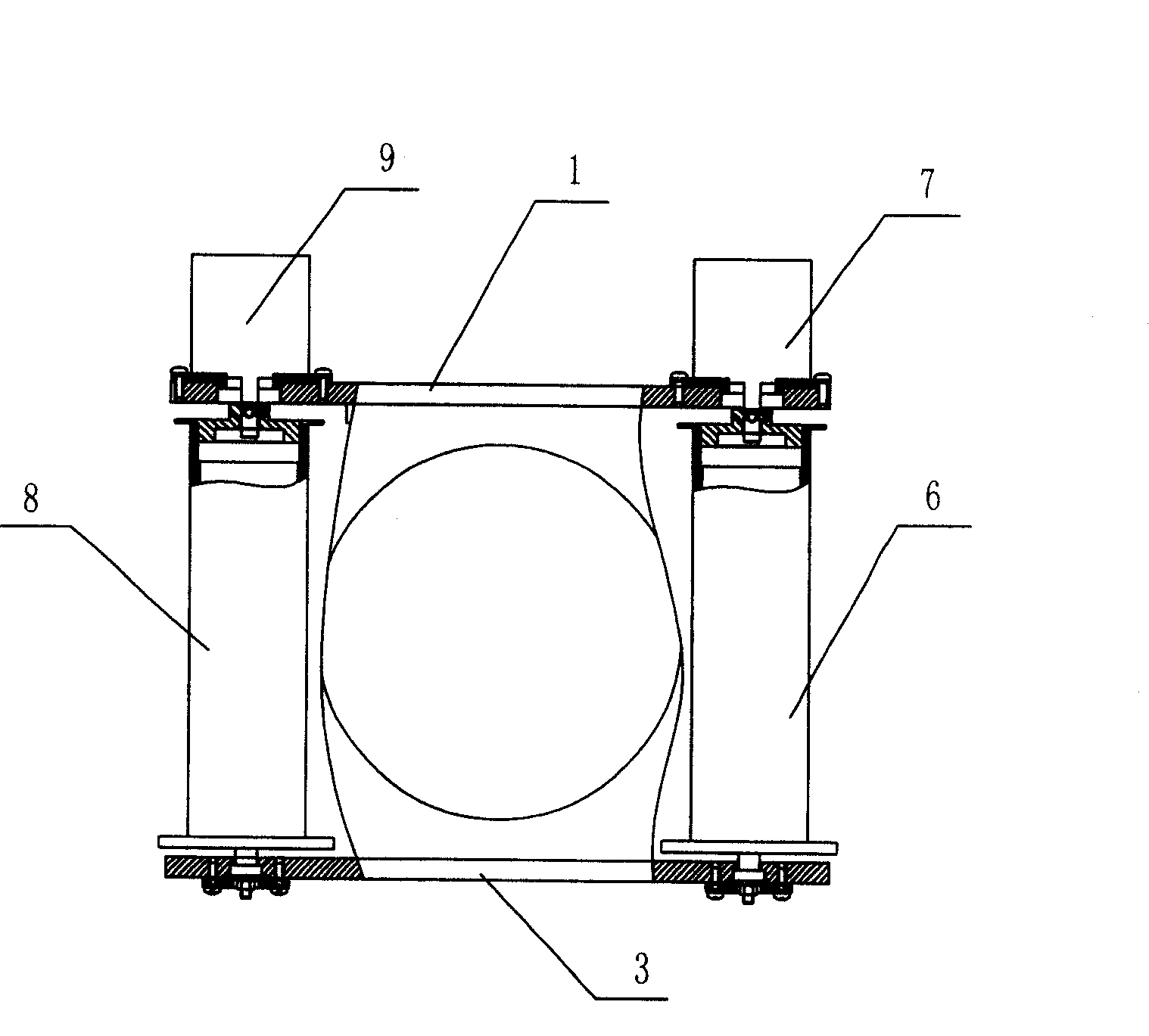

[0021] The present invention is a film winder for stage slide show, which consists of the film winder upper board 1, rear board 2 and lower board 3 to form the film winder frame, the middle part of the rear board 2 is provided with a projection area 4; the upper boards 1 on both sides of the film winder A slide storage device and a slide positioning device are installed between the lower plate 3, the slide storage device is divided into a front storage device and a rear storage device, wherein the front storage device includes a front storage shaft 6 and a The front storage shaft motor 7 on the top of the front storage shaft and connected with the front storage shaft, the rear storage device includes a rear storage shaft 8 and a rear storage shaft motor located at the top of the rear storage shaft and connected with the rear storage shaft 9. Figure 4 A schematic diagram of a three-dimensional structure of an embodiment of the present invention is shown.

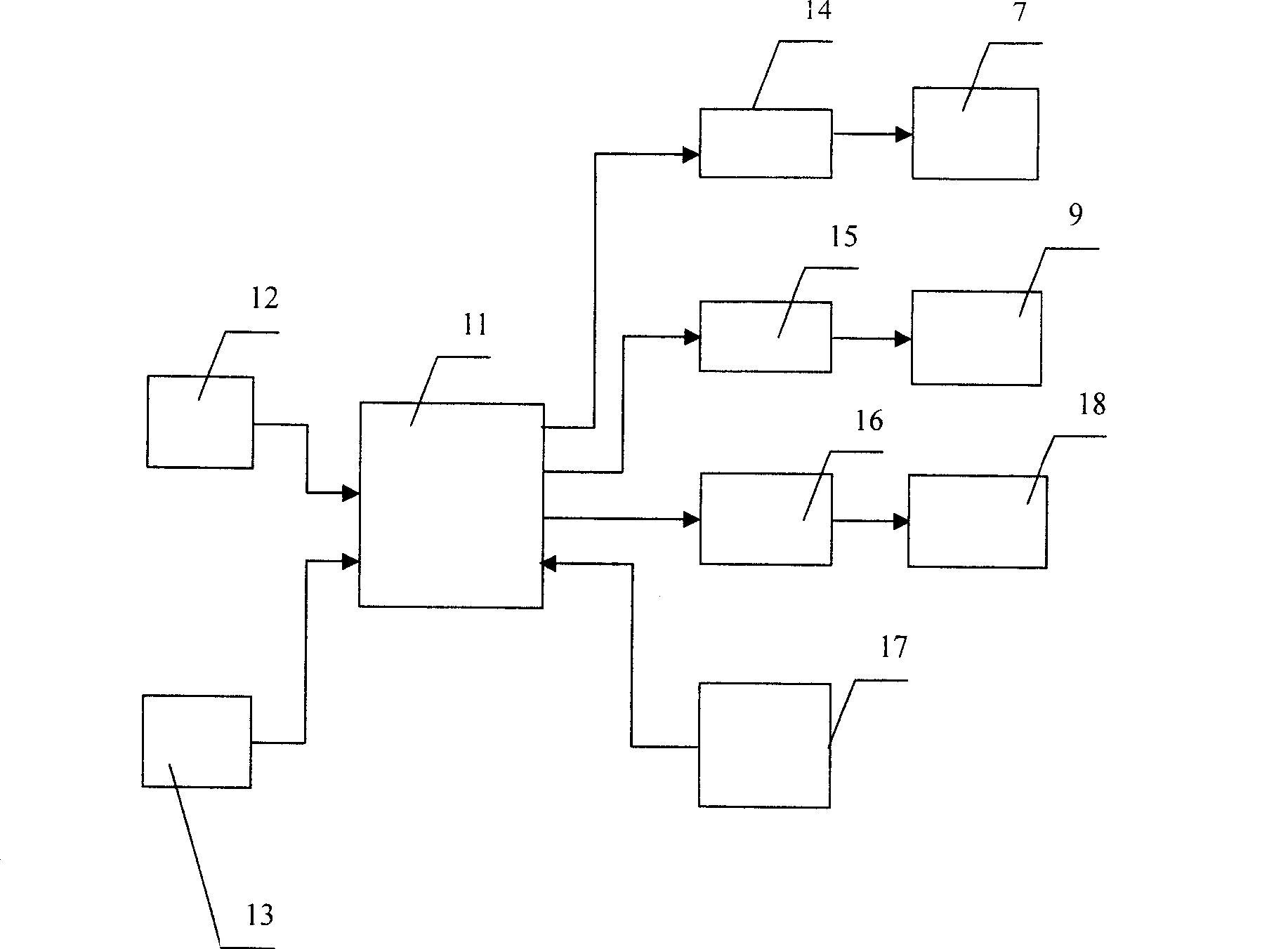

[0022] image 3 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com