Quick cooling equipment for rapid reducing temperature of product from hydrotreating reaction of catalytic cracking gasoline

A technology of catalytic cracking gasoline and hydrogenation reaction, which is applied in the direction of hydrocarbon oil cracking and petroleum industry, and can solve the problem of not being able to quickly reduce the temperature of the logistics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

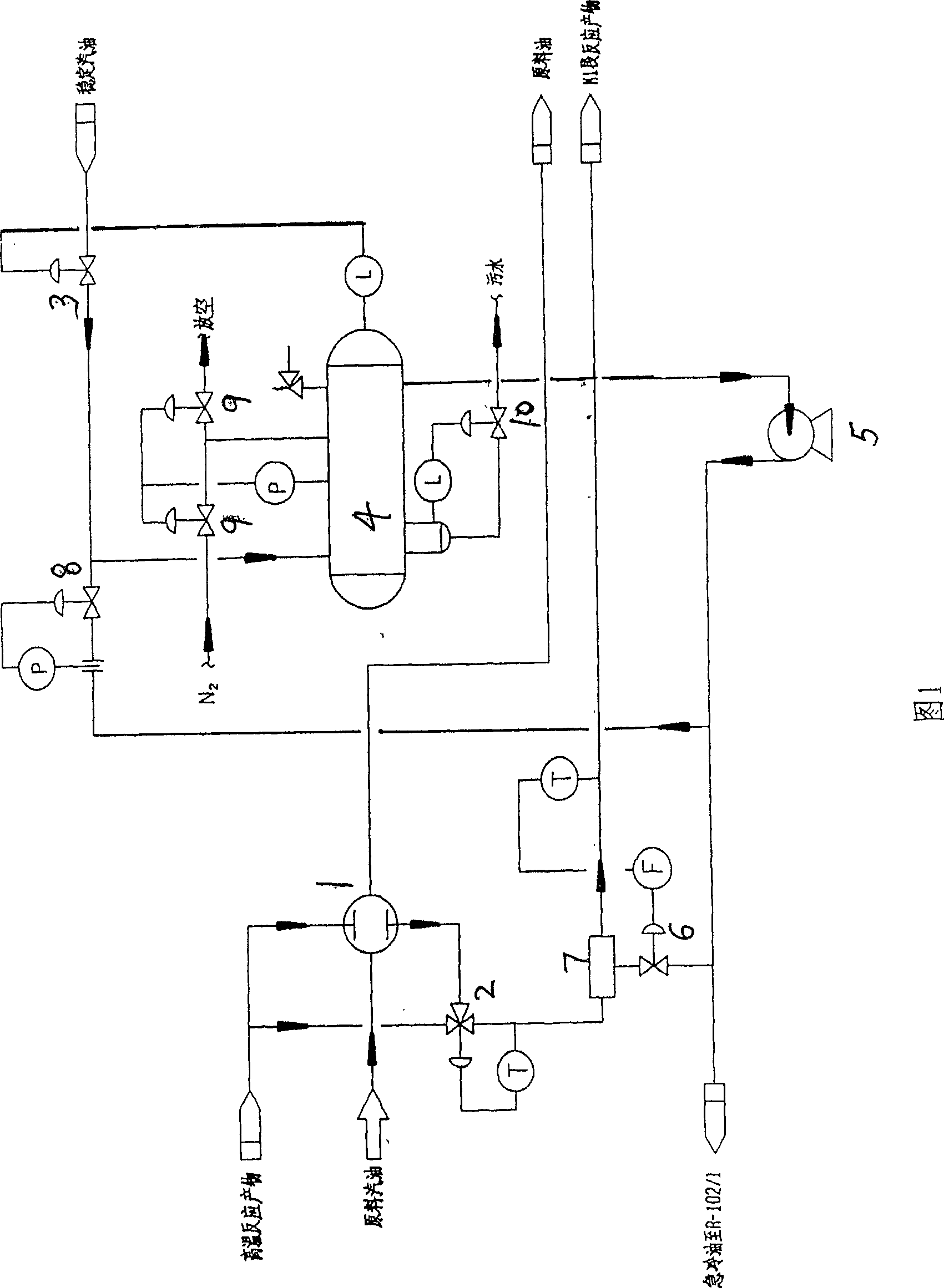

[0013] Taking the 200,000 tons / year catalytic cracking gasoline hydro-upgrading unit as an example, the description is as follows:

[0014] Under normal production conditions, in Figure 1, the high-temperature reaction product (430°C, 2.5MPa, 58800kg / h) undergoes heat exchange with the raw material gasoline (40°C, 2.9MPa, 12500kg / h) through the reaction product quencher (1), and rapidly After cooling to below 300°C, the temperature of the medium after heat exchange is adjusted through the three-way regulating valve (2).

[0015] When the reactor is overheated, the temperature of the reaction product can reach 460°C, and the temperature after heat exchange is 330°C. At this time, the temperature of the reactor and the high-temperature reaction product is lowered by means of quenching oil.

[0016] Stable gasoline (40°C, 0.85MPa, 20000kg / h) is sent to the quenching oil tank (4) as quenching oil through the liquid level control valve (3) to depressurize to 0.3MPa, and is sent out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com