Method of controlling photoresist stripping process and regenerating photoresist stripper composition based on near infrared spectrometer

A technology of photoresist and photoresist layer, applied in optics, analytical materials, optomechanical equipment, etc., can solve the problems of inability to collect strippers in real time and analyze real-time strippers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

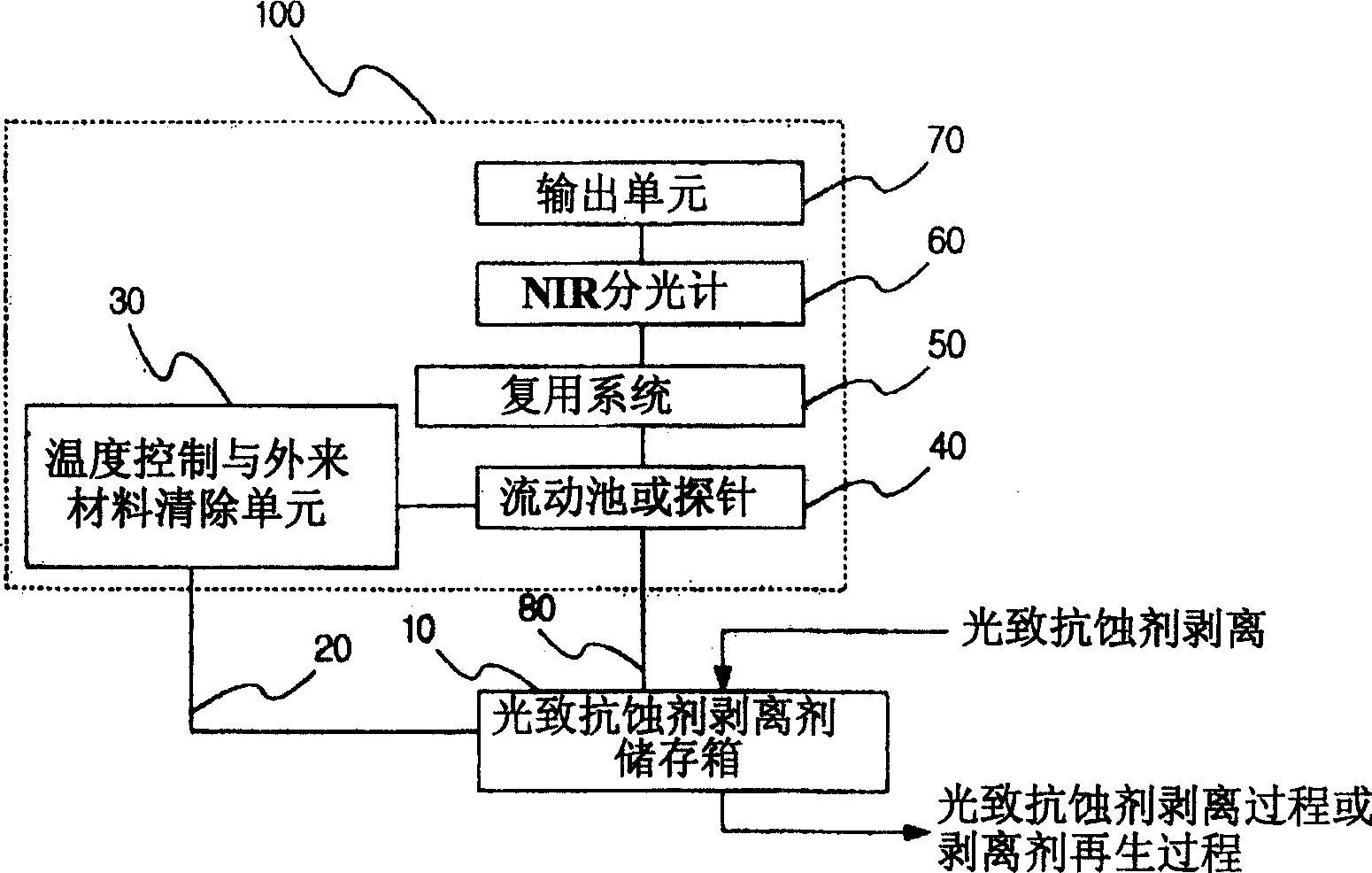

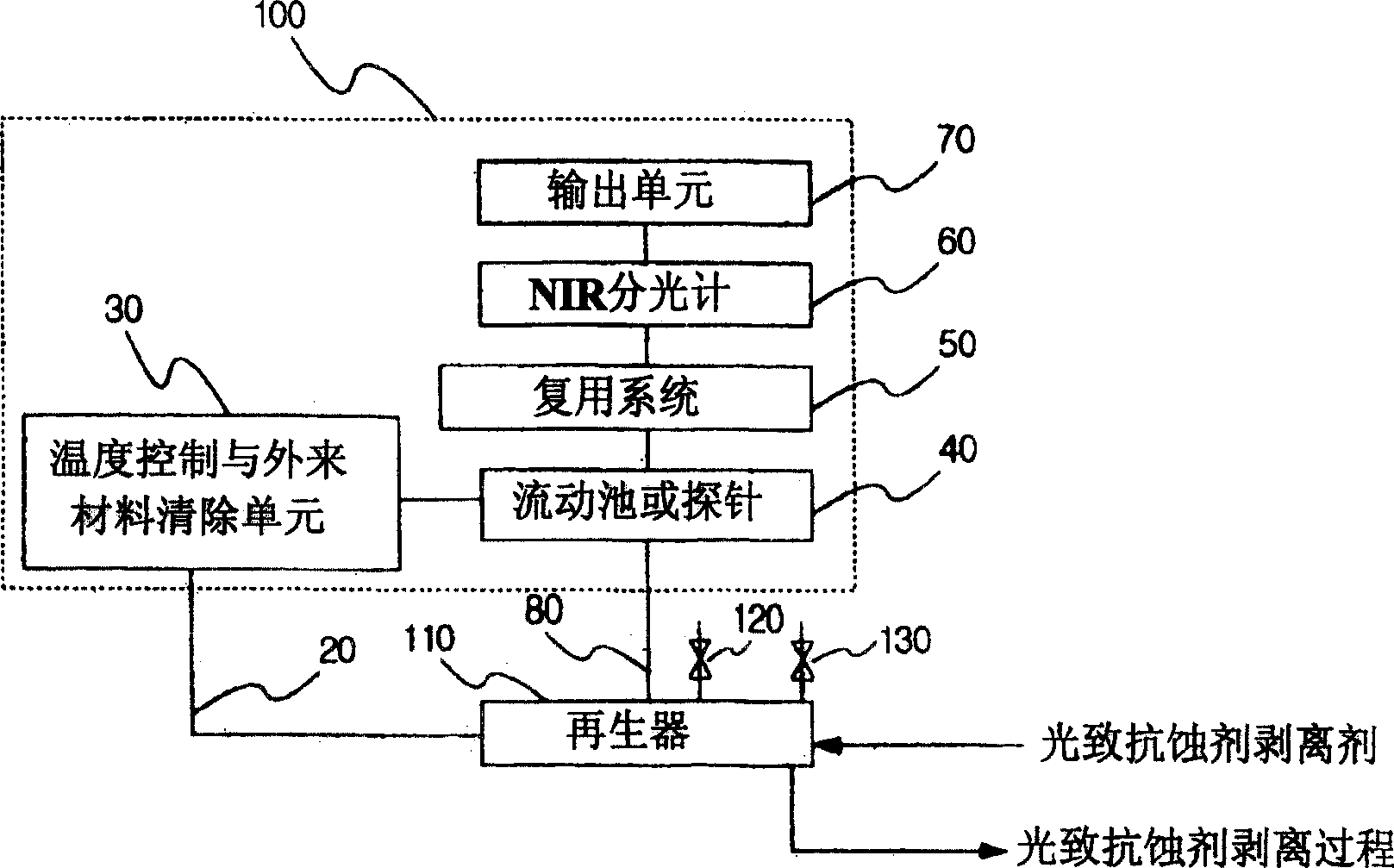

[0028] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

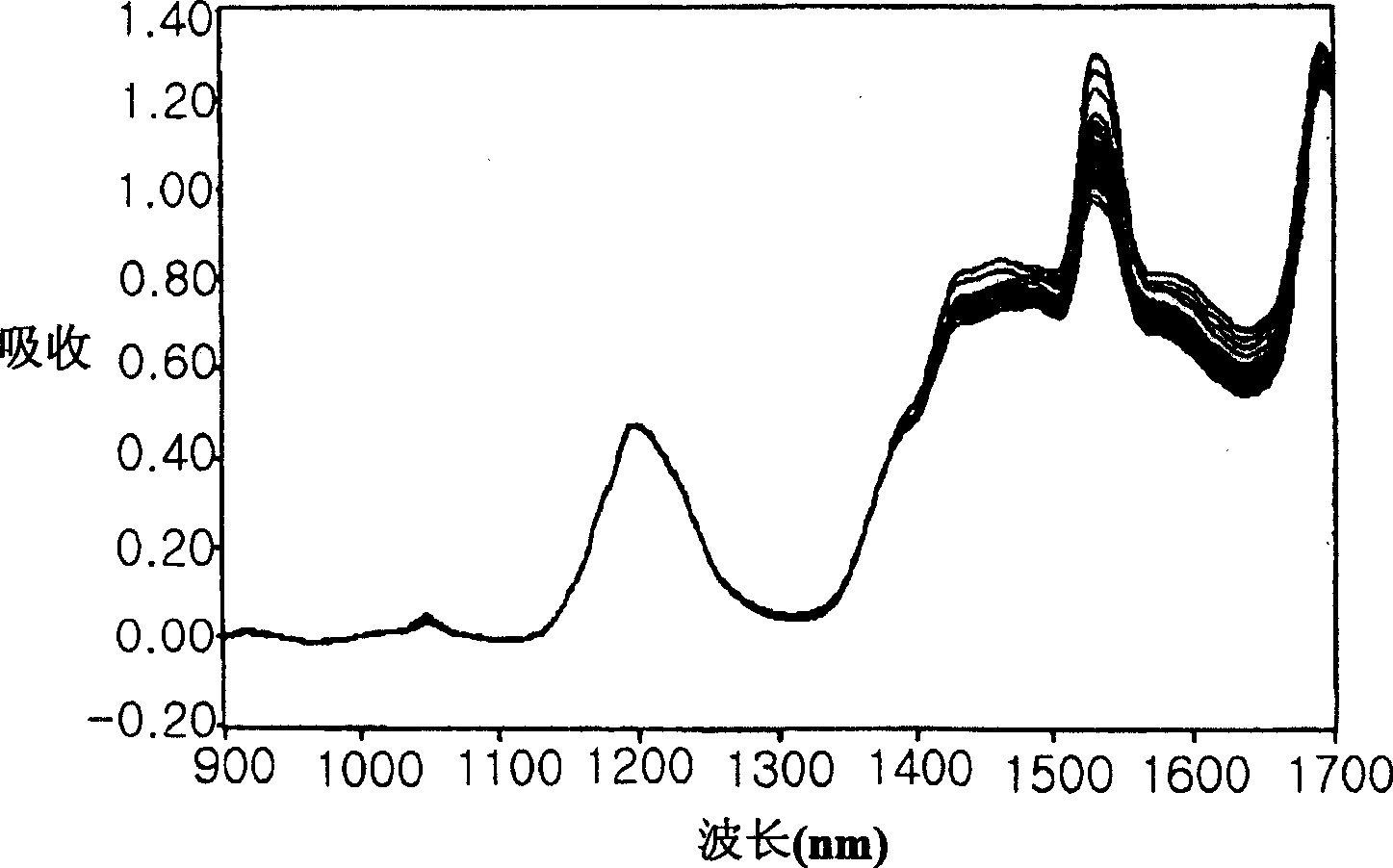

[0029] During the manufacture of semiconductor devices or liquid crystal displays, a photoresist stripper is sprayed onto a substrate covered with a patterned photoresist layer so that the photoresist can be stripped from the substrate agent layer. At this point, the photoresist stripper containing the stripped photoresist is collected into a stripper collection box located below the substrate. When the amount of the stripping agent in the collection box reaches a predetermined value, the stripping agent is delivered to the stripping agent storage box by a delivery pump. Since each component of the release agent has its characteristic light absorption wavelength, the components of the release agent can be analyzed in real time by detecting the light absorption of the release agent in a near-infrared (NIR) wavelength range using a NIR spectrometer.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com