Solid electrolyte type fuel cell

A solid electrolyte, fuel cell technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve problems such as changes and achieve the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments of the solid electrolyte fuel cell of the present invention will be described in detail with reference to the drawings.

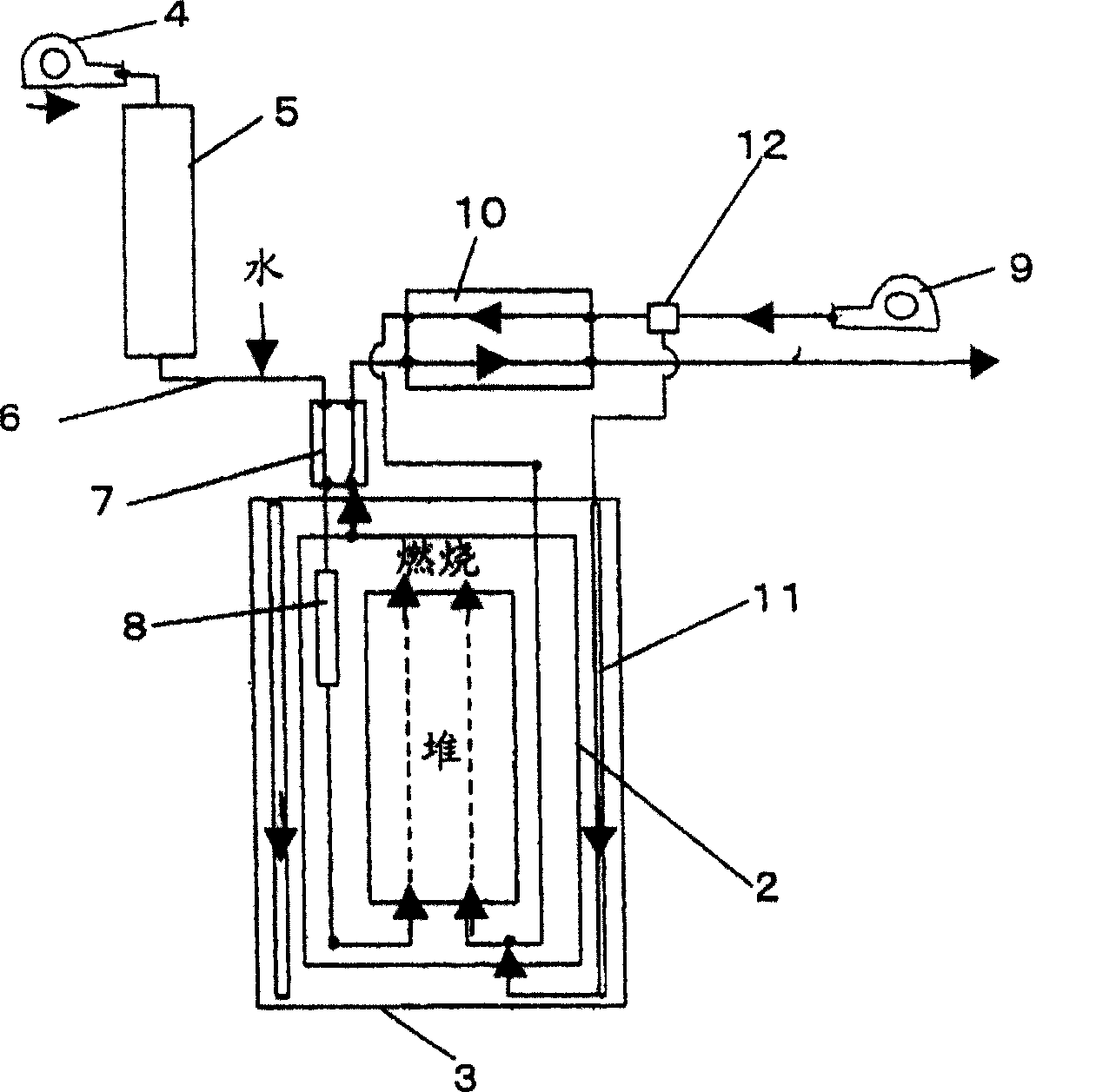

[0035] figure 1 It is a schematic diagram showing one embodiment of the solid electrolyte fuel cell of the present invention.

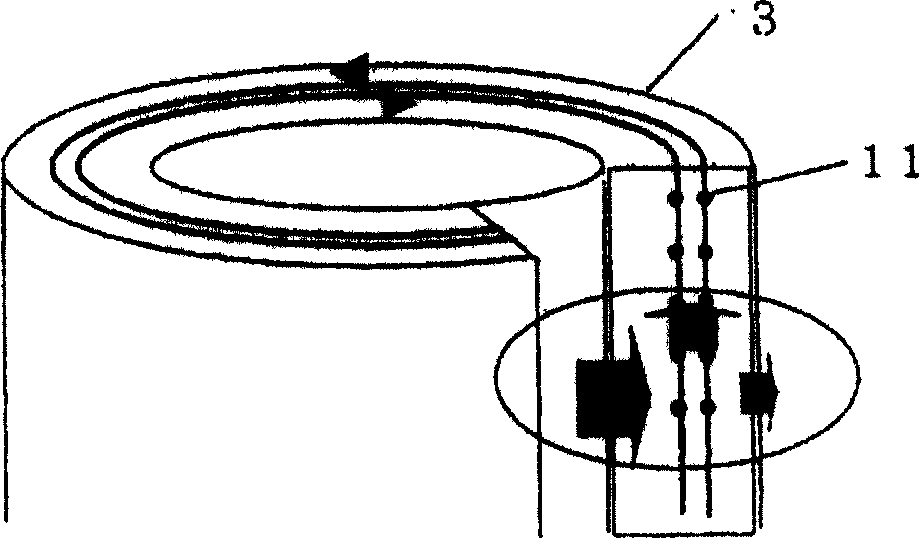

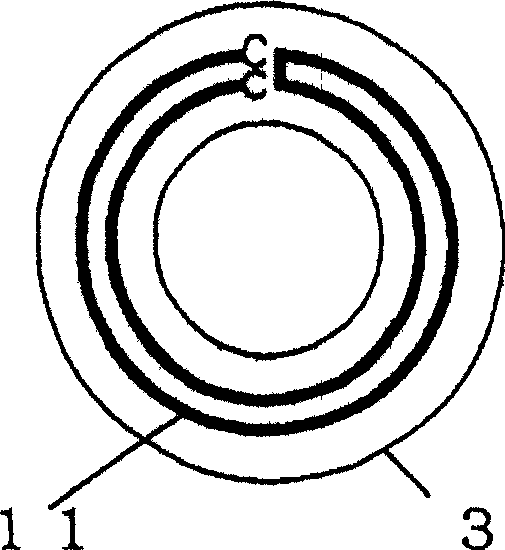

[0036] This solid electrolyte fuel cell has: a fuel cell stack 1; a storage container 2 that houses the fuel cell stack 1; a heat insulating material member 3 that surrounds the storage container 2; a fuel gas supply source 4; a desulfurizer 5 that receives fuel gas and undergoes desulfurization treatment; a water adding part 6, which adds water to the output of the desulfurizer 5 (desulfurized fuel gas); a gasifier 7, which performs heat exchange between the combustion gas from the fuel cell stack 1, And the desulfurized fuel gas added with water is gasified; reformer 8, which reforms the gasified desulfurized fuel gas added with water, and provides it to the fuel cell stack 1; air supply source 9;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com