Blade type engine

An engine and vane technology, applied in the field of fuel vane engines, can solve the problems of low engine efficiency, low conversion efficiency, unsatisfactory efficiency, etc., and achieve the effects of high fuel and transmission efficiency, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

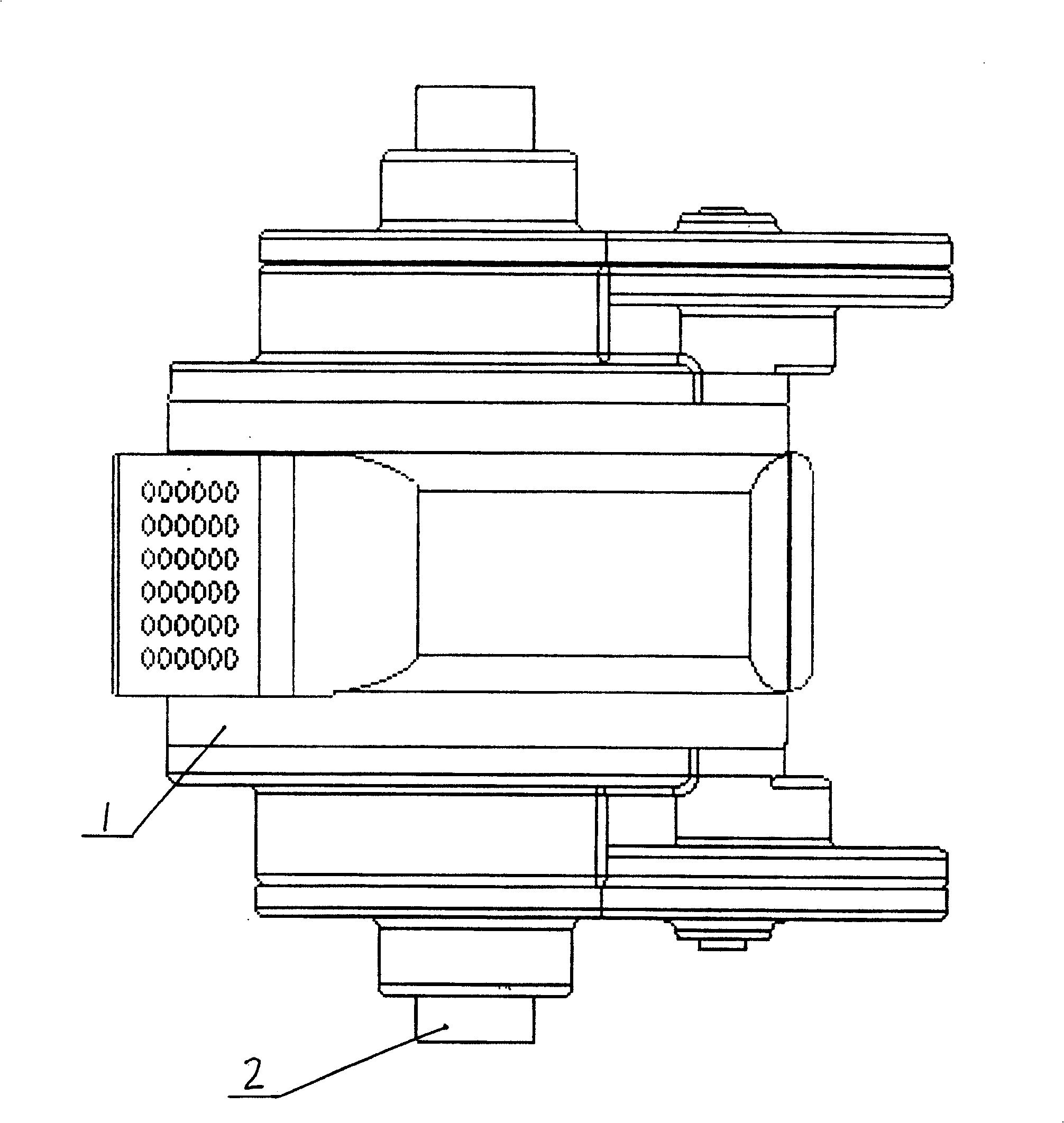

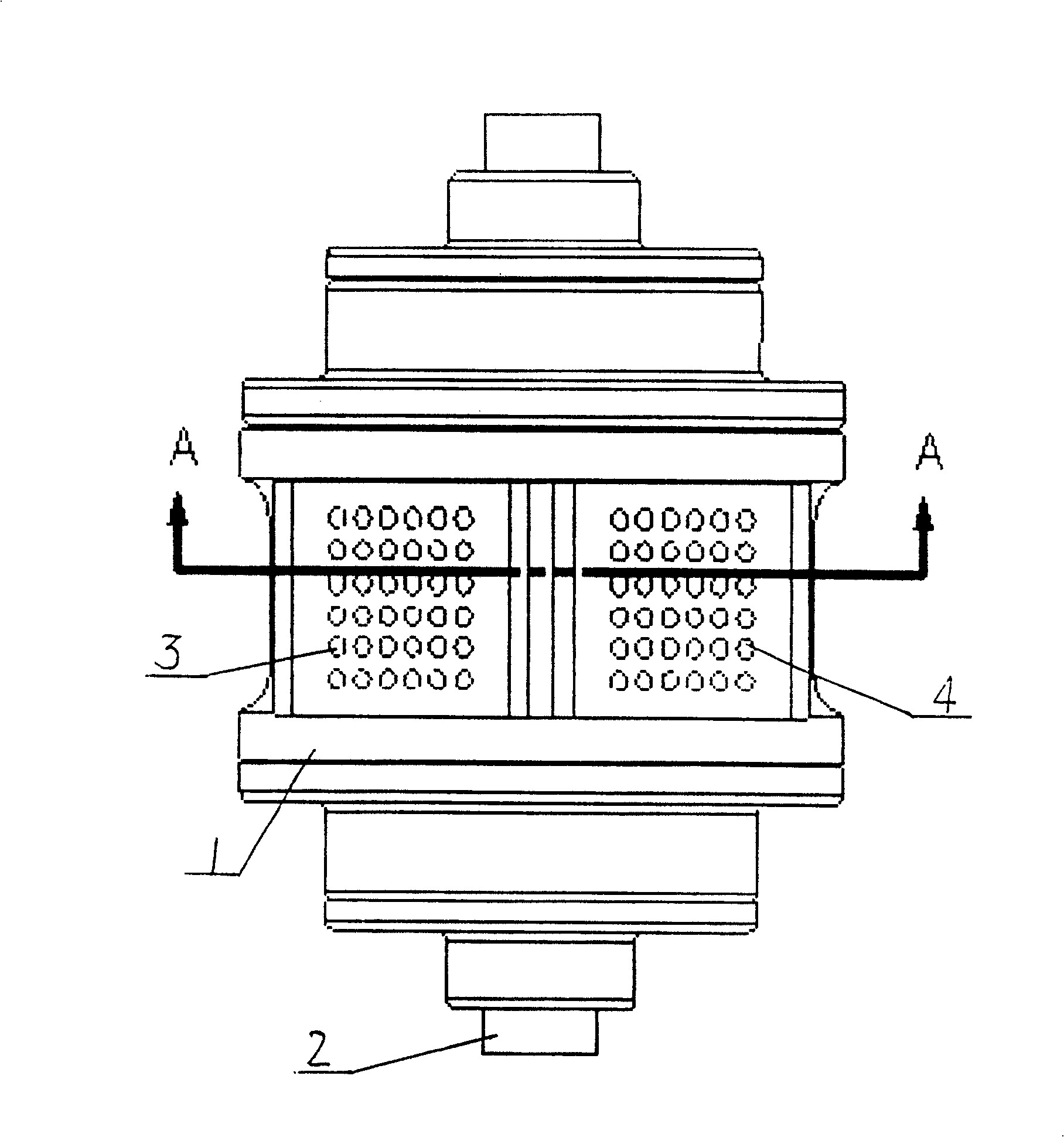

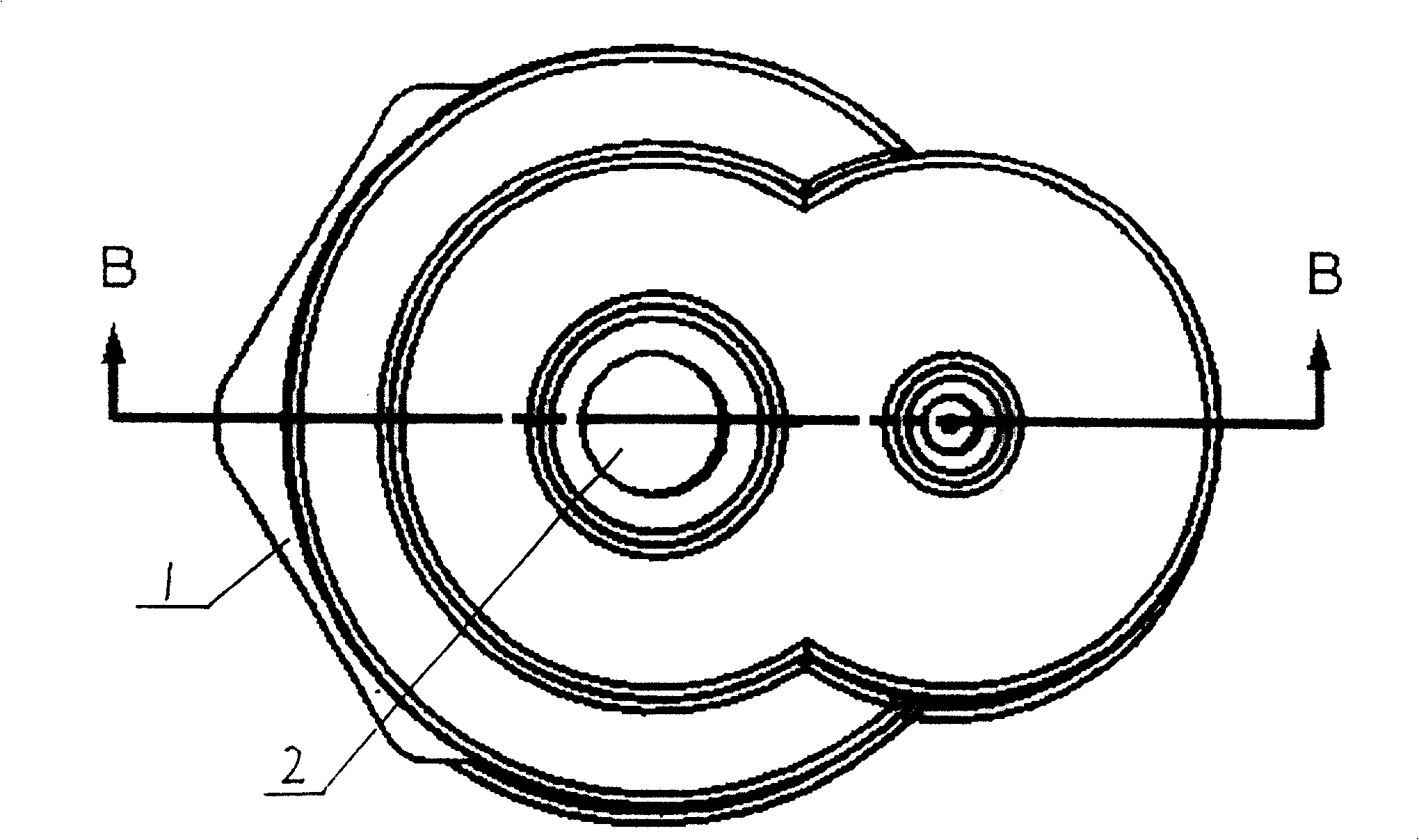

[0012] As shown in the drawings, the engine shaft 2 is fixed in the casing 1 through bearings, and the left and right blades 5, 6 are vacantly sleeved on the engine shaft 2 in the casing 1 through the bushing 12. The left and right blades 5 and 6 are slidingly matched with the casing 1 in a small gap, and there are cylindrical grooves on the left and right blades 5 and 6. 1 cooperate to form four chambers 7, so that the left and right blades 5 and 6 can move at variable speeds within the scope of the four chambers 7. Fixed left large spur gear 8 on the left blade 5, as Figure 5 As shown, the left small cylindrical gear 11 meshing with the left large cylindrical gear 8 is fixed on the casing 1 through a bearing, and the oval gear 10 is coaxially fixed with the left small cylindrical gear 11, and another transmission parameter meshing with the oval gear 10 is the same Oval gear 9 is fixed with described engine shaft 2. The transmission ratio of the left large cylindrical gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com